70 years ago, design engineer Karl Klein founded a packaging company. To mark the anniversary, current and former employees and residents of the region came together for an open day at Hassia Verpackungsmaschinen GmbH and were given an insight into the work today and how it all began.

It all started with Hassia It all began in 1953, when the designer Karl Klein decided to develop a Establish a company for the rationalised packaging of consumer goods. The vision of creating product-appropriate and consumer-friendly packaging and producing, filling and sealing it by machine - largely fully automatically - matured into a concrete idea through tireless work. Karl Klein initially began working as a contract packer for the pharmaceutical industry.

The steadily increasing demand for tablet packaging led to the rapid growth of the contract packaging company, until finally a customer from Leverkusen asked for its own packaging machines and Hassia began to build additional machines in 1955 (tablet packaging machines and sachet sealing machines) and the foundation stone for the first production hall was laid.

Solutions for food and pharmaceutical products

Many of today's The most common forms of packaging worldwide have their origins in the Ranstadt think tank. The ‚cup with the corner‘, the refreshing towel, mustard and ketchup in portion sachets, the tablet push-through pack (blister pack), portion cups for jam, butter, etc.

The Portion pack in a bag sealed on 4 sides worldwide. A variety of different products can be found on the market in this handy packaging. Whether toothpaste, shampoo, mustard, ketchup, sauces or pharmaceutical goods such as stomach gels and ointments - the sealed edge pouch has established itself worldwide as a practical and cost-effective packaging solution.

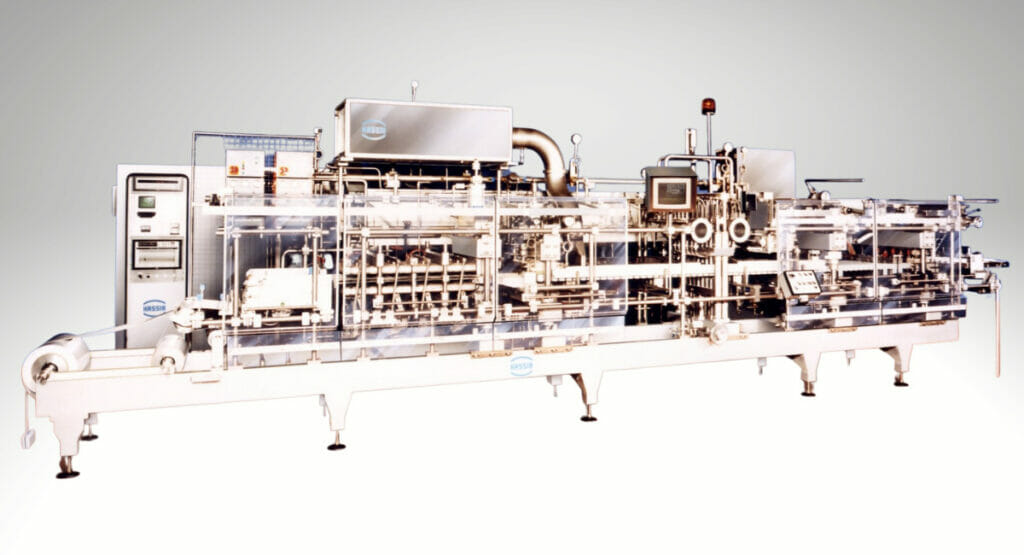

In the 1980s, Hassia supplied the First aseptic thermoforming machine for aseptic cup packaging out. The company realises the aseptic process with packaging sterilisation using the natural medium of steam, completely without chemicals. This ecologically harmless system is even used for packaging baby food in plastic cups. The aseptic process makes it possible to guarantee a long shelf life for products outside the cold chain.

The success story continued steadily in the years that followed. In 1974, IWKA AG replaced the family management and in 2007 the OYSTAR Group took over the company. In 2015, the OYSTAR Group was taken over by the Italian company IMA S.p.A., one of the world's largest packaging machine manufacturers, and is now part of the IMA DAIRY & FOOD Group. This has further fuelled international growth: Today Hassia machines in more than sixty countries around the world in operation. At the end of 2018, Thomas Becker acquired shares in the IMA DAIRY & FOOD Group and works for the group as CEO and shareholder. The world-renowned high-performance filling and closing machines for prefabricated cups and bottles under the Hamba brand are now also built under the Hassia umbrella.

From the very beginning, the packaging machine specialist has focussed on training the specialists of tomorrow itself. The trainees can expect Practice- and project-orientated training. In the specialised departments, they are taught basic knowledge and work techniques and get to know all the relevant areas of activity in order to equip them to become the specialists of tomorrow.

Source: IMA Hassia

More news about packaging machines

interpack 2026 shows trends in the packaging industry

White paper | How to make packaging machines more dynamic through lightweight construction

Three applications, one solution

Packaging machine manufacturer in flow