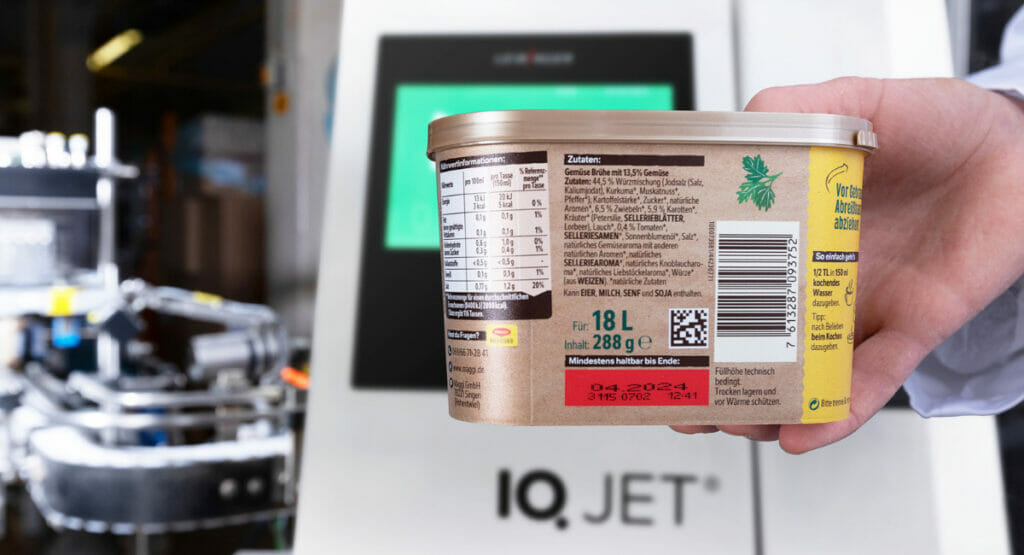

A labelling system is indispensable in the production line. But the labelling system is only a small part of the overall production line, and many companies have not really given this topic much thought. Labelling should just work, full stop. However, it is precisely this „reliable, continuous operation“ that causes many conventional labelling systems to fail in production practice. Interruptions, time-consuming start-up or set-up times, a lack of flexibility during changeovers - one thing leads to another, and suddenly the entire production line comes to a standstill. This is not only annoying, it also costs a lot of money. But there is another way. This is the clear statement from Leibinger, with the new IQJET labelling system.

The new generation of labelling focuses on Sustainability, maximum reliability and significant savings in operating costs. In May of this year, the labelling specialist from Baden-Württemberg presented the new, intelligent IQJET Coding & Marking System. The IQJET offers a Plug & print performance and maximum availability without production interruptions. It is maintenance-free for the first five years. It is also a pioneer in the field of sustainability and promises users lower operating costs.

„We connected the IQJET and it started printing immediately. Error-free. The operator practically doesn't have to intervene during operation. Cleaning is unnecessary. And changing the cartridges is easier than ever before.“

Simon Keller, Technical Group Leader, Packaging Deli / Tainer, Maggi GmbH, Singen

CIJ explains

The most common labelling systems for printing variable data such as best-before dates, codes, serial numbers etc. are continuous inkjet printers (CIJ). The great advantage of CIJs, also known as „small character printers“, is their flexibility.CIJ printers are Suitable for almost all surfaces, shapes and materials. The coding is contactless. Integration is simple, use is safe for people and the environment, and no protective devices are required. The Inks are extremely quick-drying and are suitable for almost all production environments and applications.

Leibinger clears up prejudices

A major and well-known disadvantage of conventional CIJ printers on the market is that they have to be cleaned regularly, often even at every start, so that the production line has to be stopped during this time. This happens because the ink in the systems dries up when they are not in use and clogs the lines. The result is downtime and an unsightly print image after start-up.

Not so with Leibinger CIJ labelling systems. „A Leibinger CIJ requires no cleaning routines. The technology behind it is completely different“, explains Christophe Lopez, CCO at Leibinger.

Avoidance of downtime thanks to unique product design

Leibinger CIJ printers are equipped with a Fully automatic nozzle sealing technology. When the printer is not in use, the ink is sealed in a 100 per cent airtight circuit. The ink continues to circulate in this circuit. No clogging or drying of the ink, no cleaning, no expensive downtime. „This technology is unique on the market. Airtight and completely automatic pressurised nozzle closure, This is only available from Leibinger,“ adds Christophe Lopez, who has been working in the labelling market for 15 years and knows it like the back of his hand.

When the printer is switched on, it starts up again immediately. To Consistently high print quality regardless of the ambient conditions the new Leibinger IQJET also permanently regulates the ink temperature and viscosity.

Up to 50 per cent lower consumption

Another effect of the airtight nozzle closure technology is that No solvent is used during the printing pauses becomes. In addition, the IQJET collects solvent that has evaporated during operation and returns it to the system. The IQJET therefore achieves up to 50 per cent lower consumption than conventional CIJ systems on the market.

Example: The IQJET consumes 2.7 ml of solvent per hour. Competitive printers without solvent recovery consume between 6 and 10 ml per hour. Calculated on a 3-shift operation with an average of 6,000 total hours per year, up to 43,800 ml of solvent are saved per year.

The Use up ink cartridges completely and thus prevent waste, sounds obvious, but unfortunately this is not the case in the labelling market. Conventional labelling systems often require new cartridges, even if they still have up to ten percent filling capacity. This is avoidable waste that has an impact on the environmental balance and costs. The cartridges of the IQJET printer on the other hand, are emptied down to the very last drop and can therefore be fed directly into the recycling cycle. can be recycled. In addition, Leibinger cartridges are made from just one plastic (PE) and are therefore easier to recycle.

The IQJET is also a pioneer in terms of power consumption and is the most energy-efficient printer on the market with a consumption of just 36 watts.

Integration in operation

Leibinger is setting a new standard with its IQJET for integration into production operations via Plug & Print. This is realised with Numerous interfaces, including OPC UA and an integrated PLC (programmable logic controller). With a state-of-the-art HMI with a 10-inch touch display and intuitive drag & drop operation, just like on a smart device, the system can be operated effortlessly without any prior knowledge of the system.

„Integration couldn't have been easier with the IQJET. And practically no intervention is required during operation.“

Simon Keller

Quality that lasts

The most sustainable products are those that have a long service life. Leibinger CIJ printers are produced with a Production depth of more than 85 per cent manufactured in the production plant in Germany. The focus is on maximising control over the quality and long service life of the components. High-quality products require less maintenance. This in turn means significant Savings in running costs and minimises maintenance and repair-related production interruptions.

The new Leibinger IQJET printer requires No maintenance for five years. This is mainly due to the new product design, which reduces wear and tear. For example, a constantly running main pump is not required for pressurised operation.

„Any manufacturer who values outstanding efficiency and reliability will benefit greatly from the IQJET. We at Maggi also appreciate that our employees now have more time to focus on the essentials such as safety and product quality.“

Simon Keller

More news from the magazine

Translucent paper seal labels for pharmaceutical packaging

Packaging machine manufacturer in flow

Powerful automation for mills

Decentralised signal processing with the Schmersal Safety Fieldbox