Together with industry partners and brand manufacturers, Bobst gave an impressive demonstration at its Competence Centre in Bielefeld at the end of October 2023 of how flexible packaging can be produced optimally and sustainably today. The open house event focussed on the latest technologies and integrated workflows with a strong focus on Bobst Connect. Complete solutions were presented that enable packaging manufacturers to adapt for a profitable future in a fast-moving and unpredictable market.

In order to be able to offer sustainable packaging products and materials that meet and even anticipate the changing requirements of customers and legislation, the company continues to work closely and trustingly with industry partners from the supply chain. Key suppliers to the packaging industry and branded goods manufacturers also took part in the event, at which Innovations for central cylinder flexographic printing, new materials, water-based printing inks and fully networked workflows were presented.

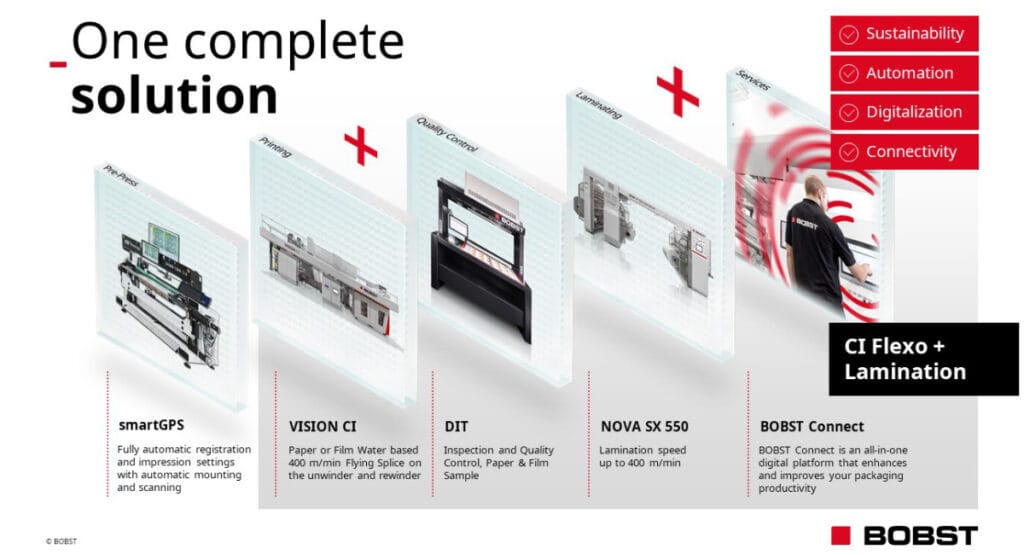

Within the integrated, end-to-end workflow of Bobst from order management and prepress to printing and laminating through to quality control. all elements of the production chain seamlessly connected via the Bobst Connect digital platform. This topic was also the focus of the programme. By recording and providing production data, the platform allows deep insights into the production processes. This enables Detailed performance analyses for better planning, improved reporting and streamlining of production processes and the continuous monitoring of production progress.

Rainer Rosenbusch, Product Manager for the Vision CI central impression flexo press at Bobst, presented the Bobst One Complete Solution. It is based on the comprehensive The company's practical expertise in flexible packaging applications and has been developed to meet future packaging production requirements. He explained how this modular solution consisting of technologies, additional devices and networking can be used to produce sustainable paper-based packaging for various applications with maximum efficiency in a workflow that is fully connected via Bobst Connect.

The centrepiece of this agile solution is the Vision CI central cylinder flexo press, which Short set-up times and fast production changes with minimised waste offers. Finally, the participants had the opportunity to experience live in the Competence Centre how several print jobs were produced on the printing machine. This demonstration bridged the gap between theory and reality in the production of sustainable flexible packaging.

More news about packaging machines

Mettler-Toledo shows inspection solutions in Düsseldorf

interpack 2026 shows trends in the packaging industry

White paper | How to make packaging machines more dynamic through lightweight construction

Three applications, one solution