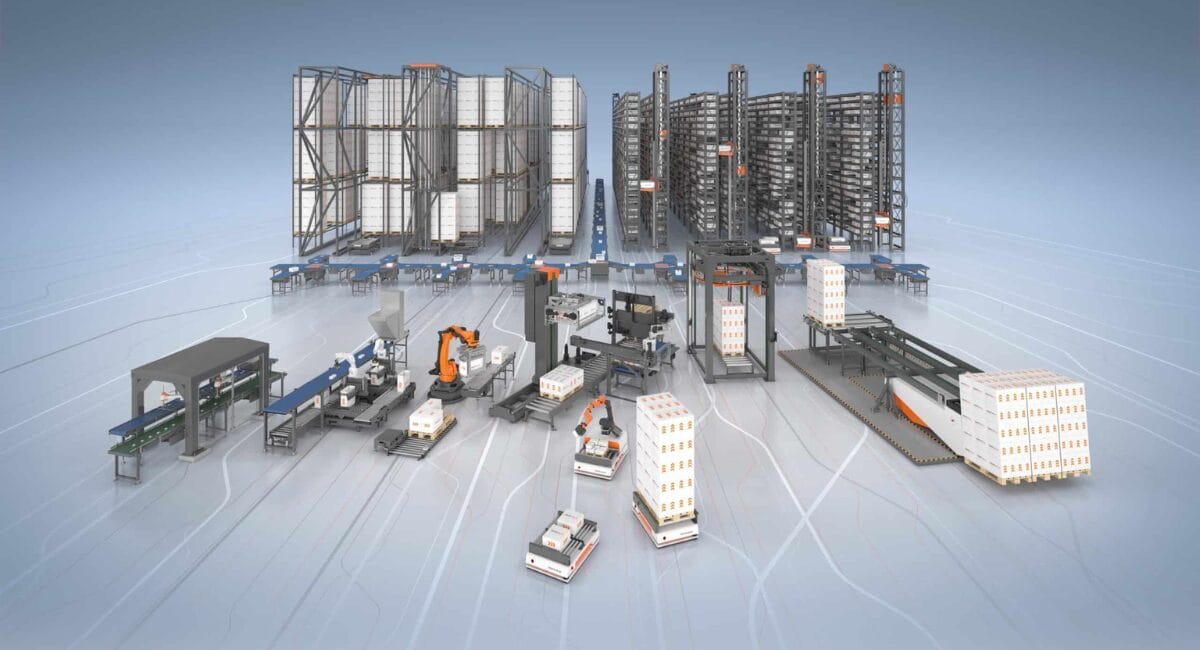

At LogiMAT, Trapo GmbH will be demonstrating a live cycle for palletising and depalletising KLT containers. The Group's solutions are customised to meet individual customer requirements.

Reusable KLT boxes can be used universally in intralogistics. The standardised design features prove their worth in highly automated production processes and complement well thought-out warehouse management. To minimise the Optimum pick-up and transfer of KLT containers utilises Trapo a portal from the HPS series (High-Speed Portal System). In Stuttgart, the portal shows a new side: at the trade fair, it operates with highly efficient performance in a limited space.

The gantry is equipped with a maintenance-friendly product layer gripper. The task: each pick up four KLT boxes and transfer them to conveyor technology - two directly onto the roller conveyor, two are buffered in parallel and then pushed off. This creates a continuous sequence for final stacking and palletising. The gantry palletiser presented here palletises boxes at a rate of more than 1000 boxes per hour. In practice Several production machines connected become.

Exactly according to customer requirements

A TLS 3600 replaces the task of several forklift trucks, which would have to cover the distance three times as often - with an enormous risk of accidents. The New generation of autonomous loading and unloading takes customer requirements and practical findings into account. In addition to box lorries, vehicles with tarpaulins can now also be loaded and unloaded autonomously. Driving has been optimised and made more manoeuvrable. The loading and unloading capacity has been further increased. The new lifting concept is a telescopic, more stable application with three lifting steps. Three Euro pallets can be loaded lengthways or - by manually repositioning the outer tines - two Euro pallets can be loaded crossways in one go.

In the latest TLS generation, the shortened switch cabinet is located in front of the counterweight - including an extendable mounting platform to simplify servicing work. A New localisation concept ensures greater security in the system. With the Plug and Play solution, the navigation software has been optimised and the number of software modules reduced. In the course of further development, the Electrics a modular designThe autonomous loading and unloading system is designed for multi-shift operation. The system does not need coffee breaks.

The sales team will answer all detailed questions in exclusive lounges at LogiMAT. Trapo enables the perfect interaction of conveyor systems, robots, customised gripper technology as well as palletising and depalletising systems. Special (de)palletising expertise: In addition to conventional solutions with articulated arm and gantry robots, the Trapo team will be providing information on the LogiMAT about the flagship, the High-performance layer palletiser HLP 6000, which can be customised for any production environment. can be inserted.

Robots and image recognition

Robot applications need the perfect equipment to perform the required task perfectly. Customised gripper technology influences and increases performance, adapted to the industry, product and package. The new generation AMR with individual superstructures for customised applications in the pallet transport segment. With particular expertise in system integration, interface definition and safety issues.

The 3D coordinates of the camera collected in machines and systems are both transmitted to the robot controller and used for analyses in ME systems. If mechanics and control are adapted to the respective production task from a single source, this minimises sources of error and saves the time-consuming coordination of several service providers. At Trapo, one Central contact for all matters - From conception to production and commissioning to after-sales service - for the entire life of the machine.

For individual care areas adapted to customer products, the company has developed a series of special designs to optimise internal transport along the production lines in accordance with the hygiene and corrosion protection requirements of manufacturers and legislators. The company's own Trapo Pack software configures the dimensions of the package and the pallet the optimum layer pattern - for perfect stack formation as the basis for stable shipping units. Once generated, layer patterns are optimised on the monitor. Layer patterns and pallet loads can be configured by the user and saved for subsequent palletising processes.

Source: Trapo

Trapo at the LogiMAT: Hall 5, Stand 5D53