GEA, provider of engineering solutions for the food, beverage and pharmaceutical industries, is presenting a new cloud-based web application for food processing and packaging lines at Anuga FoodTec. GEA InsightPartner is the latest addition to the digital product family and utilises machine data to enable a flexible response to production challenges.

GEA InsightPartner was developed to support food processors and packaging companies in achieving important production goals. The focus here is on maximising machine availability, minimising downtime, avoiding unplanned stoppages and efficient resource management. This service Increases efficiency and productivity, reduces costs and lowers total cost of ownership of the plant. With immediate access to historical and real-time plant data, InsightPartner enables better production management based on far-reaching analyses and insights from continuous monitoring. This makes it easier to identify optimisation potential and increase plant service life.

Digital innovations are changing the food industry and enable them to increase production while reducing energy consumption and waste volumes. GEA supports its customers with high-performance systems, advanced sensor technology, cloud connectivity and sophisticated analytics to enable them to produce more efficiently and achieve their ambitious sustainability goals.

The main features of GEA InsightPartner at a glance:

- Data-supported decision-makingThe new system: facilitates optimum machine utilisation by providing immediate access to live information around the clock.

- Support with maintenance and troubleshootingsimplifies the planning and execution of maintenance, minimises downtimes and enables faults to be identified and rectified quickly.

- Monitoring of relevant KPIsMaintaining an optimum production level on the basis of collected data.

User-friendly data access and real-time monitoring

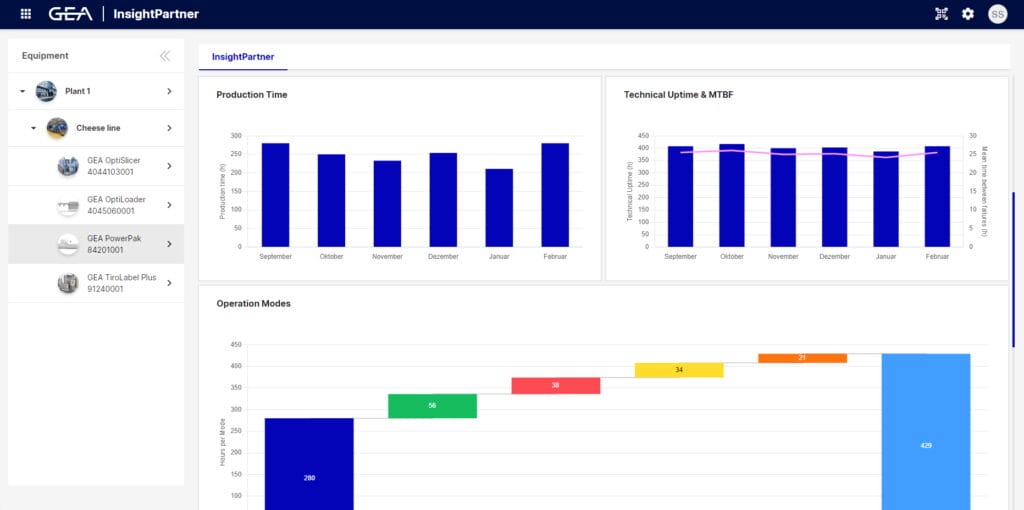

The web application provides a user-friendly interface through which technical and operational staff can access historical and real-time machine data. This ensures that performance can be compared with the most important KPIs, which benefits productivity. The system also notifies about maintenance requirements and uses trend analyses to avoid potential downtime.

Solution for detailed performance monitoring

InsightPartner simplifies troubleshooting and speeds up diagnosis and troubleshooting to a high degree. This contributes directly to improved maintenance efficiency and reduced downtime. The comprehensive monitoring dashboards provide a detailed overview of system operation and enable the user to address potential problems proactively.

GEA's suite of digital solutions, including InsightPartner, RemotePartner and the GEA Cloud, offers a holistic approach to supporting systems over their entire life cycle across the board. These offerings prioritise security and transparency and ensure secure data storage and analysis.

Retrofitting existing or equipping new machines

InsightPartner is available for a wide range of new GEA food processing and packaging machines and can be retrofitted to existing equipment. It is part of the GEA Service Agreement programme, which is supported by the combination of different service products generates added value. The „Starter Package“ for new machines includes InsightPartner as a basic element and offers customers advanced analyses, improved KPI transparency and proactive maintenance recommendations.

Source: GEA

GEA at Anuga FoodTec: Hall 5.1, Stand C101 D029