Set-up, downtimes and maintenance times, energy efficiency and recycling rates are increasingly becoming the focus of companies. Processes are accelerating, workflows are changing and the individualisation of end products is being driven forward. Systems from Nestro Lufttechnik GmbH, Schkölen, support the industry in meeting these new challenges and vacuum dust, punching waste and endless edge trim in an energy-efficient and sustainable manner.

A two-element JET NSJ 9/5-3370 intermediate filter with a total height of over nine metres for an air flow rate of 15,420 m³ per hour is on display. Visitors have the opportunity to view the filter through numerous viewing windows, Take a look inside the modular in-line filter. The filter area, the discharge area and the chamber above the filter unit with the high-performance vacuum fans are visible. The filter can run continuously as it is cleaned sector by sector with „JET compressed air pulses“. Customised equipment with filter cartridges or filter bags as well as various discharge options result in customised solutions for indoor or outdoor installation.

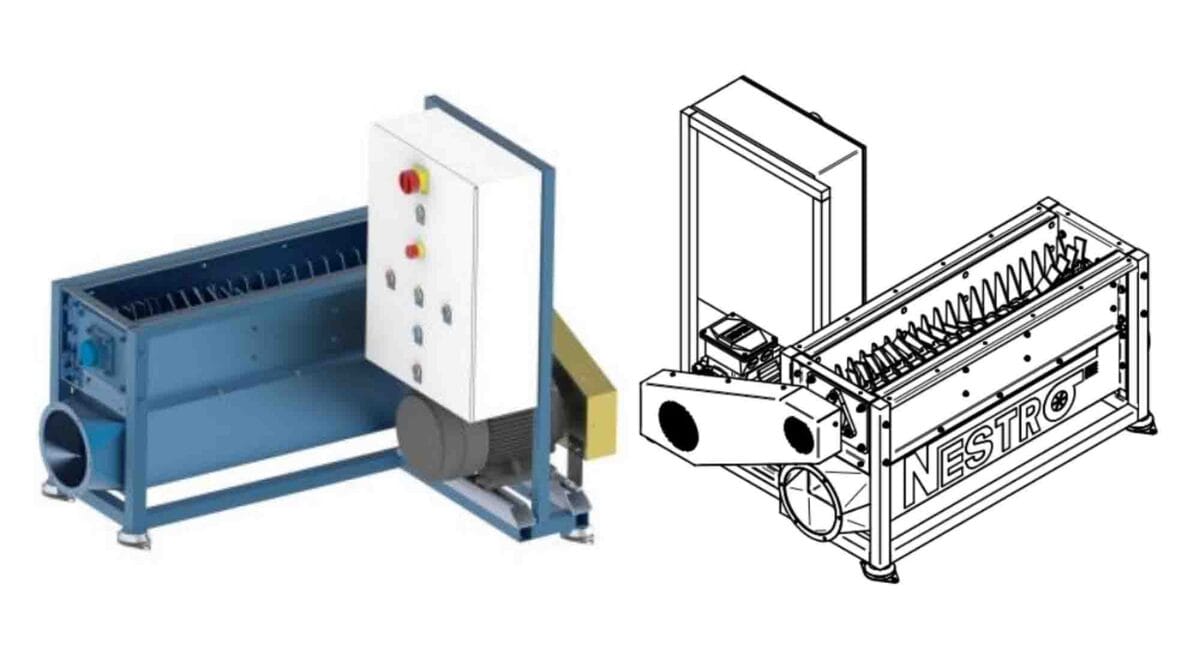

For the first time, the company is presenting its new High-speed shredder for shredding sheets of paper and cardboard for use in vacuum transport to a wide audience. The NSV 1000 (vertical version) on display shreds up to 12,000 sheets with a maximum thickness of 15 millimetres and a maximum sheet width of 1,000 millimetres. The single-shaft shredder with its hardened blades has already proven its reliability in several live tests. The experts use a cutting model to demonstrate the function of its shredding fan: pneumatically transported material of considerable length or in continuous format is already shredded in the air flow.

Source: Nestro

Nestro at drupa: Hall 1, Stand B61