ABB Robotics has signed an agreement to collaborate with California-based Zume, a global provider of innovative, compostable packaging. ABB will supply robotic cells that will enable Zume to produce sustainable packaging on a global scale and help reduce dependence on single-use plastic.

ABB will supply more than 1,000 MFC (moulded fibre manufacturing cells) with up to 2,000 robots to Zume over the next five years. Zume will supply the cells to Integrate and install at locations worldwide. Additionally uses ABB its programme management capabilities and automation experts from the Global Solution Centers network. This should enable the modularity and speed required for the introduction of the solutions. Potentially, this could millions of pieces of sustainable packaging every year are produced.

Increasing desire for sustainable packaging

Manufacturers are under increasing pressure from consumers and policy makers to find alternatives to single-use plastic packaging. New packaging must be sustainable and at the same time easy to mould and as cost-effective as plastic. The Zume packaging material is made from sustainably harvested plant material, that is generated during agricultural production, including bamboo, wheat and straw.

Plant material uses significantly less water and energy and reduces CO₂ emissions compared to the production and disposal of plastic packaging. Unlike plastic, plant-based material is 100 per cent biodegradable and simply decomposes after use.

„The automation of the production of sustainable packaging from Zume with ABB robots makes it a practicable and economical alternative to disposable plastic. With Zume, we have the potential to remove trillions of pieces of plastic from the global market, conserve scarce resources and support a low-carbon world. The Robot automation is expanding the possibilities today and making the world more sustainable through more efficient production that reduces energy consumption, emissions and production waste. Our collaboration shows what is possible when organisations committed to a low-carbon society work together.“

Sami Atiya, President of ABB Robotics & Discrete Automation

Cooperation between ABB and Zume creates new opportunities

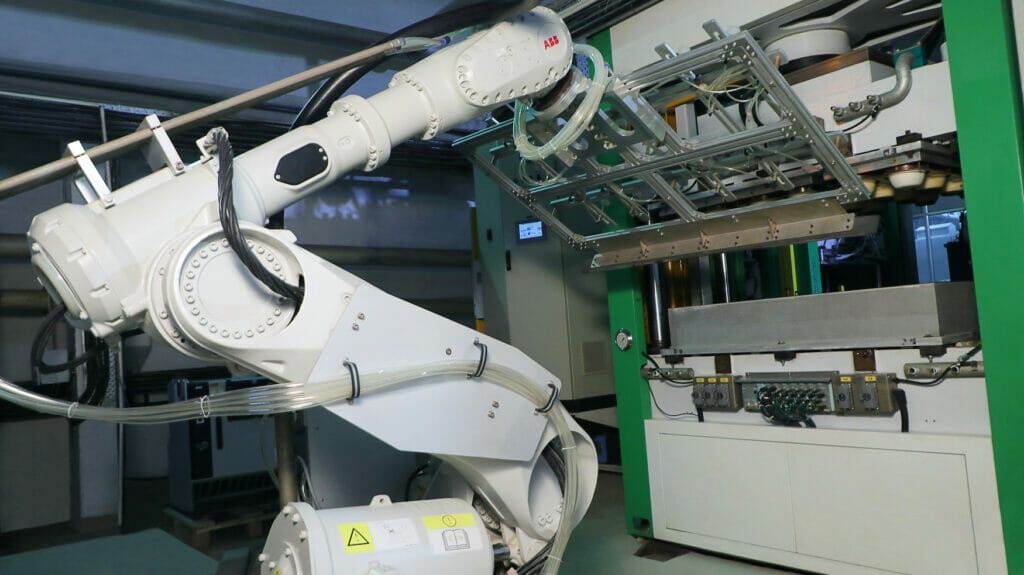

Zume has developed and patented an innovative manufacturing process with which Compostable packaging for food, cosmetics and consumer goods can be produced. The containers are formed from the plant material using Zume's fibre forming cells, which are integrated with two ABB IRB 6700 robots. Each cell processes up to two tonnes of agricultural material every day, resulting in 80,000 pieces of sustainable packaging. are created.

In co-operation with ABB Zume plans to equip factories with up to 100 robot cells each. With the Automation, speed and scalability, that the MFC offers, each site would have the potential to process 71,000 tonnes of agricultural material per year and thus possibly produce up to two billion packages per year.

„We estimate that by 2050 there will be more plastic in the world's oceans than fish. That's why it's important that we all move away from single-use plastic. Leveraging ABB's global automation experts to develop and integrate automation solutions for our customers will make the Revolutionising the packaging industry and showing what sustainable production can look like. The flexibility and scalability of ABB robots enables an efficient automated production process. This means that we can offer a practical, cost-effective and compostable alternative to plastics and help manufacturers to become more environmentally friendly.“

Alex Garden, Chairman and CEO of Zume

A Pilot project was realised by Zume and ABB at Satia Industries Limited, one of India's largest manufacturers of wood and agricultural paper. A plant with ten production cells produces 20 tonnes of paper per day. Wheat straw into 100 per cent compostable packaging processed for a range of industries.

„Our collaboration with Zume and ABB puts Satia Industries in a position to Our customers expect high-performance, affordable and reliable products that are sustainably manufactured and easily compostable. are to fulfil and exceed. Not only do we create significant added value for the company, but we can also support the planet by offering sustainable products.“

Dr Ajay Satia, CMD from Satia Industries

SourceABB Ltd

ABB - More news

ABB prepares for double trade fair appearance

ABB automates packaging process at BiFi

Red Dot Award for ABB

Automation with flexible robots