As a manufacturer of high-quality roll labels, bsb-label covers a particularly wide range of market requirements. The company is one of two pilot customers where BST eltromat was able to put its innovative POWERScope 5000 video surveillance system through its paces in practical use.

Letterpress, screen, flexo and digital printing: with its ten printing presses using different technologies, the bsb label GmbH their customers in matters of Labelling, Labelling and Decoration of products offer all options. „In eight of our ten printing presses, web guiding systems from BST eltromat guarantee perfect throughput of the materials to be printed,“ explains Brigitte Alers, Managing Partner of the Bielefeld-based roll labelling specialist. „We also use video systems from this manufacturer to check the print quality in three of our machines.“ The high-speed die-cutters from Feldbaum + Vogt and the finishing machines from Grafisk Maskinfabrik are also used at bsb-label. Systems from BST eltromat for use.

[infotext icon]Founded in 2004, the bsb label GmbH is a company of the Bielefeld-based bsb group. With 20 employees, bsb-label produces in Bielefeld High-quality roll labels for practically all requirements of the global consumer goods industry and other sectors such as the automotive and electronics industries. The Batch sizes from single units to many millions.[/infotext]The collaboration between the two companies dates back to 2008. Back then, bsb-label had the existing systems for web edge control and video monitoring in its Gallus ECS 340 narrow-web flexographic printing press replaced with solutions from BST eltromat. „Our sister company bsb-proprint, which specialises in sheet-fed and web-fed screen printing, had already been using systems from BST eltromat for years,“ recalls Brigitte Alers.

With a 100 per cent inspection system SHARK 4000 LEX the partnership reached a preliminary climax at the end of 2014. This system is used in a packaging machine that bsb-label primarily uses for the Control of large label rolls uses. The SHARK 4000 LEX is provided with masters that the system uses to check whether all labels on the rolls correspond to the references and whether the grids have also been removed correctly. If this is not the case, the errors are manually removed from the process.

Genuine partnership

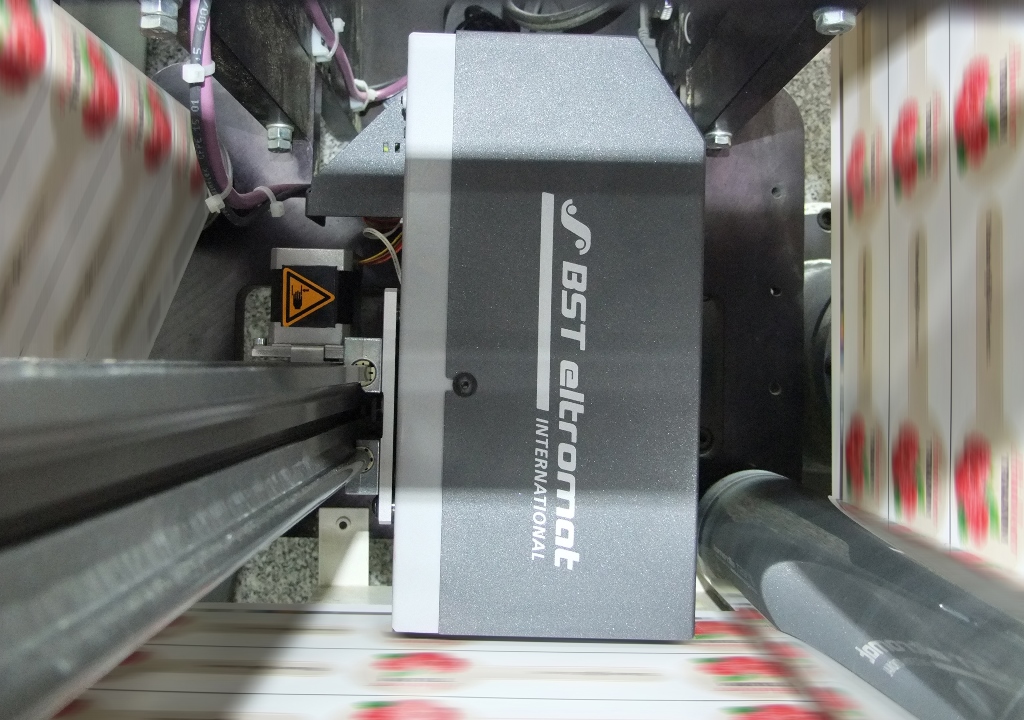

In spring 2016, BST eltromat enquired whether bsb-label would be interested in beta testing the then brand-new POWERScope 5000 digital video monitoring system. In August 2016, this was installed in the Gallus ECS 340, which bsb-label uses to produce a wide range of different roll labels. „Many customers expect us to 100 per cent control of their products. Flawless label rolls are a prerequisite for them to be able to fully utilise the productivity of their machines,“ says Peter Bellmann, Head of the Printing Department at bsb-label, emphasising the outstanding importance of quality assurance in the production of roll labels. In view of this market requirement, state-of-the-art technology is just good enough. A practical test of the new POWERScope 5000 therefore fitted in well with the concept.

The new product presented at drupa 2016 POWERScope 5000 for narrow and medium-width printing processes was developed from scratch by BST eltromat. Starting with the traverse on which the camera is mounted and positioned in printing machines, through to the camera and the software, including the user interface: all core components were to be improved compared to the previous version, POWERScope 4000.

New user-friendliness

In view of the diversity and complexity of market requirements, bsb-label attaches great importance to Simple operability. „BST eltromat has reduced the user interface of the new video monitoring system to the essential functions and thus made it particularly clear,“ emphasises Daniel Dießelhorst, responsible for strategic purchasing at bsb-bentlage. The machine operators only have to enter a few order parameters in the menu, such as the format lengths and widths. They can do this either via the quick access keys on the external keyboard or via the multi-touch monitor. Depending on the space available and customer requirements, the external keyboard can be flexibly installed in printing machines.

The POWERScope 5000 also relieves the machine operators of work steps. „For example, we can save camera positions including image sections, zoom and other settings and call them up again at any time. The camera then automatically moves to the desired positions. Our machine operators need a maximum of one to two minutes per job to set up the system,“ says Peter Bellmann. With Up to five order changes per day on this machine over the course of the year, this means an enormous Time and cost savings.

Quality always under control

With the split-screen function, machine operators can view standing images on the 21.5-inch wide monitor with excellent image quality. Live images The camera can compare reference images from production with live images and enlarge image sections without distortion using the wear-free electronic zoom. In this way Details of the printed labels such as the quality of the register and irregularities can be reliably recognised. Even the punching contours are clearly visible. The digital camera has a high resolution, while the high-performance LED flash illuminates the material webs evenly. „Daniel Dießelhorst attests to the high reliability of BST eltromat's technology: “So far, no system has ever failed. The POWERScope 5000 has also been working reliably since commissioning.

Always new tasks

Even after the test has been completed, bsb-label continues to approach BST eltromat with new requirements. „The development department at BST eltromat also regularly asks us if we have any new requirements,“ says Alers, praising the company's commitment. Eventually, bsb-label will convert more of its printing presses to the new video monitoring system. The Compact design of the camera unit play a role, as it takes up very little space in the printing presses. In the near future, bsb-label is considering the use of a Wide-range sensor from BST eltromat after. These sensors with measuring ranges of up to 460 millimetres optimise web guiding for changing web widths, for example. Sensors of classic web edge guiding systems reach their limits here.

„With the high production speeds of our machines, our printers need systems that reliably recognise the print quality, including the register. The systems from BST eltromat work so well that we no longer have to worry about this,“ says Bellmann, summarising his experience.

Faulty labels no longer reach the customer. The systems also make it easy for bsb-label to document the quality assurance process.

Competence centre for labels, signs and lettering

The bsb group maintains a facility equipped with all technical refinements. Research and development, in which it tests the UV resistance or adhesive strength of labels and signs, for example. Customers often send in new products so that the experts can take their time to test which type of label or sign best fulfils the requirements. „Before new products leave our premises, they are tested in every conceivable way. Even if they are exposed to harsh working conditions, labels often have to last ten years or more,“ explains Brigitte Alers.

The combination of decades of expertise, the broad-based, consistently quality-focussed production process and the company's own laboratory make the Special market position of the bsb group. The extensive warehouse for special materials, the serialisation options including a duplicate check developed in-house and UL approval (Underwriters Laboratories) for the North American market also set the company apart from the competition.