The success story of today's BST GmbH began in 1960 with the development of the first register control system for gravure printing presses by the company eltromat. Since then, the company has expanded its product portfolio to include numerous innovative system solutions and is now one of the world's leading full-service providers of quality assurance systems for the web-processing industries.

The slogan on one of the first advertising materials of BST Servo-Technik, which was founded on 1 July 1979 and later developed into BST GmbH in 2014 through a merger with eltromat, was: „A new name for web guiding systems“. A name that is now an integral part of the industry. What drove and united the four BST „founding fathers“ Wolfgang Küster, Gerd Reining, Timm Matzutt and Fritz Hermann was an unwavering spirit of innovation, drive and entrepreneurial vision. From the very beginning, the young company pursued a philosophy of thinking and acting globally and established international co-operations with partner companies. in the USA, the Netherlands, Great Britain and Denmark - a recipe for success that has proven its worth for decades and is the basis for today's pioneering position. BST justified.

The area of activity of BST, which has been under the joint management of the elexis AG Executive Board (Alexander-Felix Heck and Ingo Koesfeld) since 2022, now extends far beyond Germany: Following the founding of BST France in 1983, the subsidiaries (North America, Japan, Italia, Iberica, Latina, Turkey, India, Shanghai, South East Asia and Korea) followed. At the beginning of 2021, the Jöllenbeck and Leopoldshöhe production sites were merged to form the new company headquarters in the Altenhagen district of Bielefeld: 26,000 m² of space here offer the best conditions for continuing the BST success story. Over 360 employees at the main plant in Bielefeld and a further 600 employees at the international locations work every day to optimise their customers„ production processes with the help of innovative products and services - true to the BST promise: “Perfecting your Performance".

Pioneering milestones in product history

First-class products require first-class quality. This generally applies to the production or further processing of web materials such as packaging and also for film extrusion, printed electronics, the production of battery cells or narrow web printing. To ensure smooth production processes and high-quality results, sophisticated technology is required for continuous quality monitoring. BST has been demonstrating its pioneering spirit and innovative strength in this area for decades.

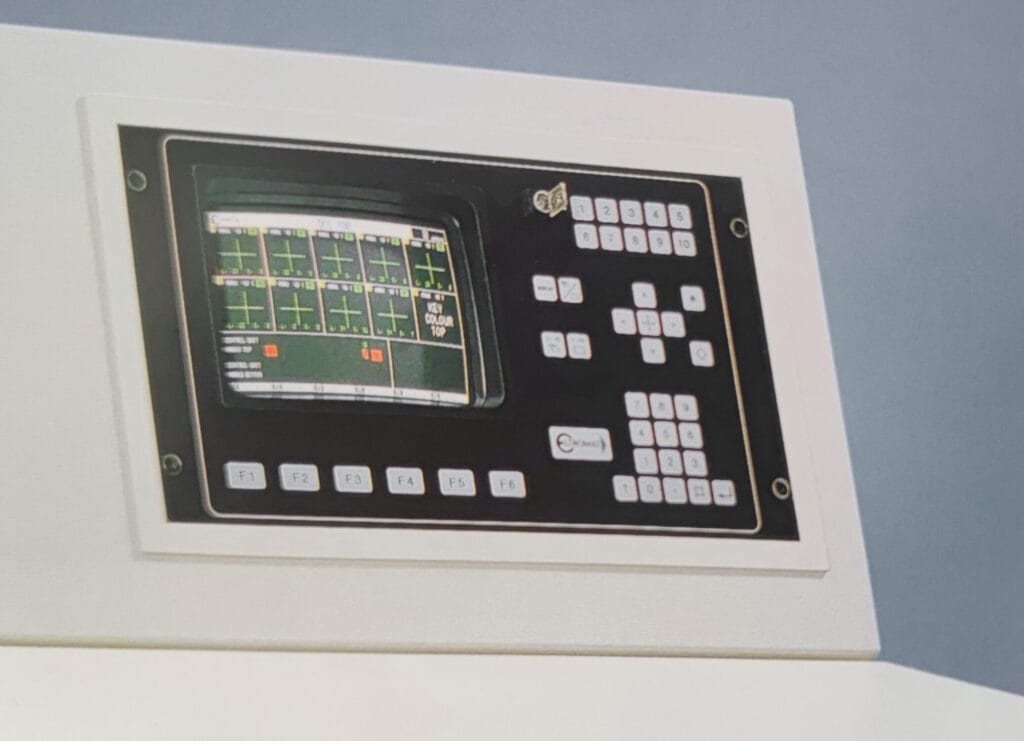

In its founding decade, the company laid the foundations for further significant innovations with two key products that played a key role in shaping the packaging industry: In 1974, the world's first register control system with fibre optic sensors was developed, followed in 1979 by the development of the analogue compact controller EKR 1, the first web guiding system. Until it was replaced by the ekr 1000 digital controller in 1990, the EKR 1 was used successfully worldwide and ensured the highest quality and precision in the production of packaging materials.

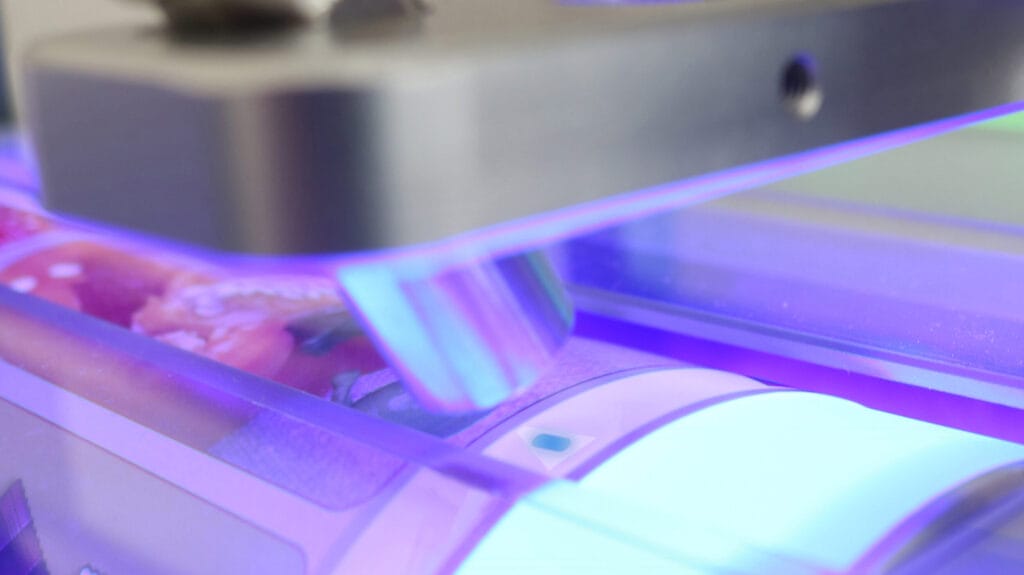

In the 1980s and 1990s, BST GmbH built up its Portfolio for quality assurance in the packaging and printing industry The first register controller specifically for offset printing was launched in 1982, followed by the first camera-based colour web monitoring system WEB Video 86 in 1986, the first 100 percent inspection system in 1990, and in 1995 BST set standards with the first shaftless drive solution for liquid packaging printing presses.

This pioneering spirit is still being consistently pursued today: 2012 saw the market launch of a Inline colour measurement system with spectral colour measurement, and in 2018, BST launched the FrameGuide, a globally unique Rotating frame design for web guiding which enables maximum precision in the smallest possible space. BST launched ProView, a product innovation in the field of video web monitoring, at the beginning of 2022: The individually adaptable system monitors printing processes even at web speeds of 1,000 metres per minute.

Customised solutions for every area of application

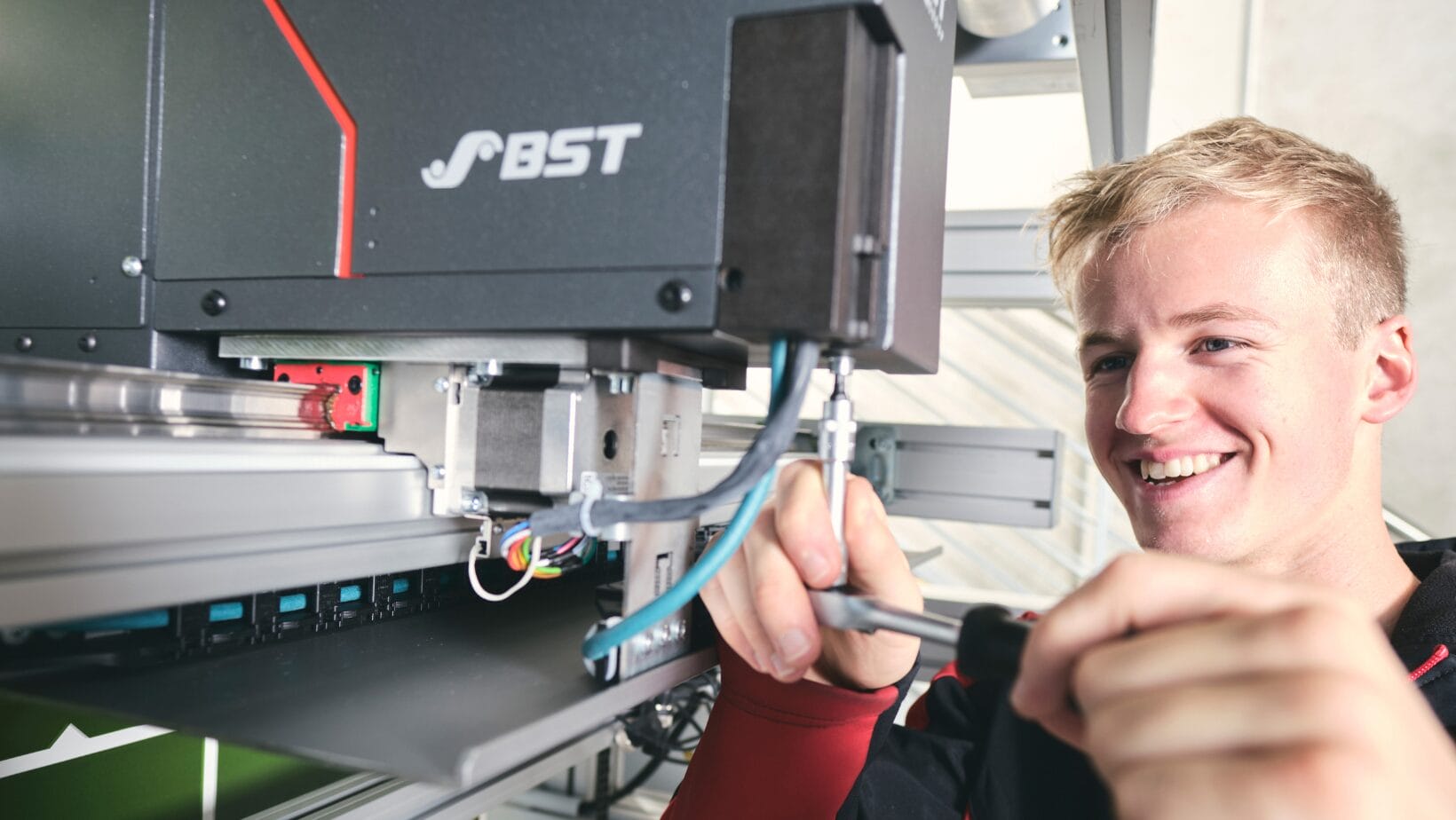

Depending on the application area and requirements, customers can choose between individual components, standard applications or complex networked systems. The focus is always on optimising the fit between customer needs and products. Thanks to the Close-knit global sales and service network BST provides comprehensive customer advice right from the start in order to tailor the solution precisely to the customer's individual requirements.

Whether it is a matter of controlling the web path in a wide variety of manufacturing processes, recording print marks or complying with specified colour standards, the company offers the perfect solution. Thanks to their modular design and flexible plug-and-play technology, BST solutions can be optimally integrated into existing industrial infrastructures. What all BST systems have in common is the added value for the customer. In concrete terms, this means less time and costs, higher production rates and flawless results every time. However, BST systems not only ensure consistently high-quality production results, but also make a significant contribution to speeding up production processes and sustainably optimising the entire value chain. By detecting, documenting and analysing faults at an early stage with the help of BST quality assurance systems, manufacturers can reduce their material waste in a targeted manner and significantly increase overall plant efficiency. In this way, BST also consistently fulfils its responsibility to protect the environment and climate and to conserve resources.

The product portfolio for holistically optimised production processes is rounded off by SmartDataCentralised data management with open interfaces enables the Integration of different systems, including systems and sensors from other suppliers. Thanks to web position-accurate quality data, this can be utilised and processed across all processes. This enables seamless quality documentation and maximum quality control of the end product.

Customer-oriented and demand-optimised systems with a future

Whether for commissioning, maintenance or repair: With locations in eleven countries on four continents and around 100 service employees in the field BST offers a seamless international service network. The company thus supports its customers throughout the entire production process, from material production to further processing. The company's goal for the future is to continue to optimally fulfil the needs of its customers and to meet the growing requirements of the web processing industry with innovative system solutions. In particular The rapidly growing e-mobility sector is an exciting market for BSTTo ensure that customers in this segment have low production costs in view of longer distances and higher output, the processing of the material webs for the production of lithium-ion batteries must be absolutely precise.

„With a broad product portfolio and new high-end solutions, BST also solves this task thanks to its expertise, experience and passion for perfection and process optimisation in all web-processing industries.“

Alexander Heck, Managing Director of BST since the end of 2022