At the Crailsheim-Dinkelbühl dairy, 427,00 litres of raw milk are processed into cheese every day. The products have a high moisture content, which must be taken into account during production and the packaging process. A vacuum system from Busch Vacuum Solutions now ensures stable production and faster cycle times.

An endless white conveyor belt constantly moves through the production hall in Crailsheim, Baden-Württemberg. Three recesses next to each other are constantly filled with blocks of white cheese by skilful hands. A colourfully printed film is placed over the packaging before it is evacuated, sealed and cut to size. In the meantime, a robot has already erected the cardboard boxes into which a Vacuum gripper arm gently lifts in the freshly packaged cheese. It is then sold under brand names or as a private label in supermarkets and discount stores throughout Germany.

The Crailsheim-Dinkelsbühl milk plant was founded back in 1927. During the peak season from April to August, the co-operative's 232 employees work in three shifts, otherwise in two shifts. Each year they process 158 million litres of cow's milk from 335 farms in the region into 21,300 tonnes of cheese. In various fat and creaminess levels, in brine, diced in oil, with herbs, chilli or olives, as semi-hard cheese, natural or smoked. They have been honoured with nine gold and two silver awards from the German Agricultural Society DLG.

Milchwerke Crailsheim-Dinkelsbühl attaches great importance to the quality of raw materials. The same goes for binding and sustainable business relationships. The Raw milk is collected every day in our own tanker lorries from the cooperative's farms, which operate GMO-free according to ecological criteria. The modern in-house laboratory controls and monitors all production processes. Production is also halal and kosher certified.

Five packaging lines, one vacuum system

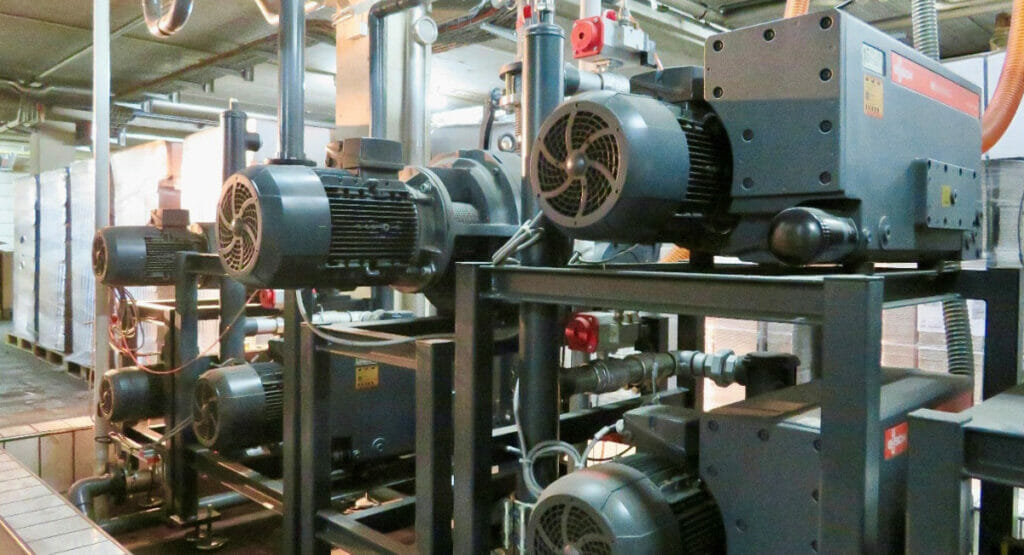

The five packaging lines are supplied with vacuum from a separate machine room. There, a pressure-controlled vacuum system from Bush, consisting of three R5 rotary vane vacuum pumps and three PANDA vacuum boosters including control cabinet and vacuum vessel, the Necessary vacuum level - precisely adjusted to the moisture content of the respective cheeses. And not only for the thermoforming of the various types of packaging, their evacuation and sealing, but also for the Erecting the large shipping cartons and final insertion of the cheese packaging.

The challenge in packaging cheese lies in the high moisture content of the products. The experts from Busch therefore paid particular attention to sufficiently large filters and an integrated moisture separator for the whey. The turnkey solution was installed over a weekend in 2021. Production then continued directly with the new system on Mondays. The system has been running smoothly ever since.

Enormous energy savings

„Previously, we used Venturi nozzles to generate a vacuum. Their air consumption was extremely high. It was actually pure energy wastage. With the new vacuum system from Busch, we save 38,000 kWh per year. We received 40 per cent of the investment sum for the vacuum system back from the Federal Office of Economics and Export Control (BAFA). Busch compiled all the necessary documents for the subsidy application for us.“

Josef Vögele, Managing Director of Milchwerk Crailsheim-Dinkelsbühl

However, the old vacuum supply was not only not very energy-efficient, it also had too low a pumping speed for the desired increase in the number of cycles. Vögele is delighted: „With the new vacuum system from Busch, we can up to twelve cycles per minute instead of nine. The vacuum is applied much faster and leads to a significant increase in productivity - while at the same time reducing energy consumption.“

Markus Otterbach, the Technical Manager responsible for maintaining the systems, is also extremely satisfied with the new vacuum system: „We pack very moist products, sometimes with spices. This also produces cheese crumbs. Nevertheless the vacuum system from Busch works smoothly. We don't really have to worry about it. Just top up the oil every now and then. We don't do anything else. Practically no maintenance is required.“

More news on food packaging

Researchers develop compostable food packaging

Dry forming goes industrial: Yangi starts fibre tray production

Printing inks for packaging hold their own in a weak market environment

One.five supplies high-barrier paper for vegan cheese