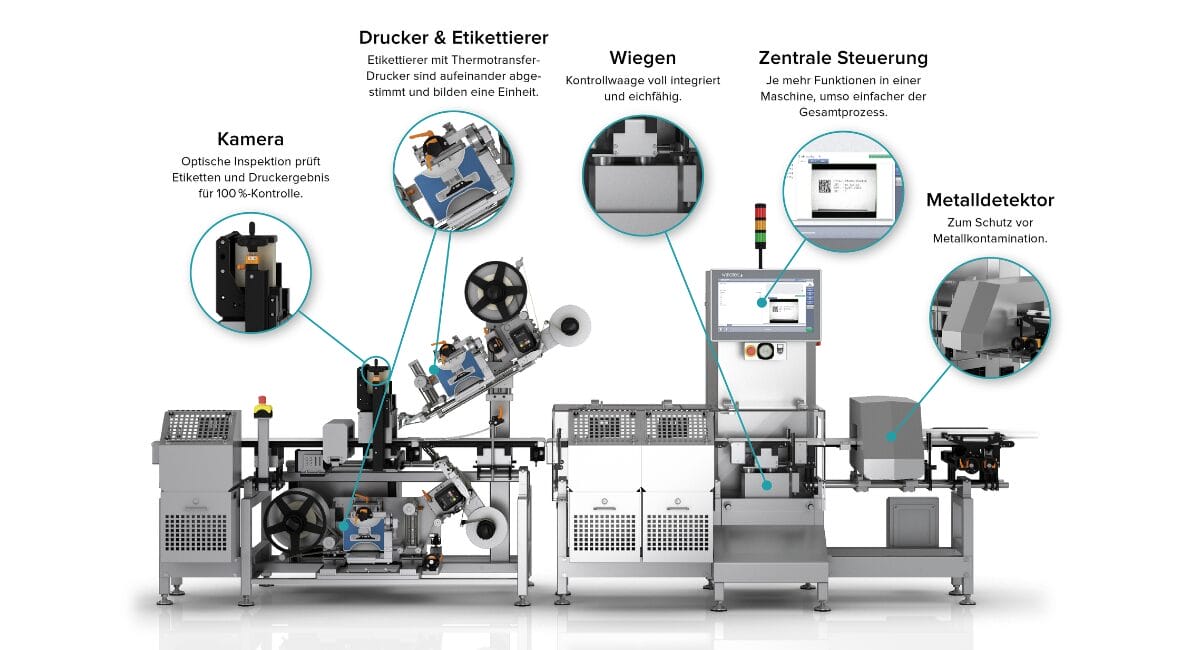

The forthcoming change in the labelling of products for the retail trade will play a central role at Wipotec GmbH, Kaiserslautern, on site and in the company's activities surrounding the trade fair.

The checkout systems in large supermarkets are being upgraded. Retailers and manufacturers are working on pilot projects in focus groups. The common goal: the Introduction of 2D codes on packaging by 2027. For most producers, this means a change in the packaging process. Where a 1-D barcode was previously pre-printed in the packaging design, an additional 2-D code will be required in future. As this code contains batch-specific information, it is printed on the line. Printing systems that cannot provide the required resolution are generally used in this process step today.

Many manufacturers are already labelling their products with codes to coordinate logistics and warehousing. QR codes are also used to provide general information about the product and brand. The classic barcode is also used as a standard for the checkout. With the introduction of batch-specific 2D codes for the retail trade packaging only needs one code. If this is generated with batch-specific information on the line, the entire supply chain right up to the end consumer can access the same digital image of the product. If the 2D code on the packaging is standard, manufacturers can add a serial number to its content. This allows the Clearly determine the authenticity of a product.

As the additional 2D code contains batch-specific information, it cannot be printed with the packaging design. This task is performed by the printing technology at the point in the production process where the batch number and best-before date were previously printed. As the codes are significantly more complex and require a higher resolution than the previously printed text, the demands on printing technology are also increasing.

This entire development is not based on a legal requirement. However, forward-looking producers are already planning for the future and investing in a marking or labelling solution that can be used today. Expiry date and batch number printed as text which can be expanded tomorrow to include a 2D code.

Wipotec at Anuga FoodTec: Hall 6.1, Stand B-010/D-029