Cone Pal produces corrugated cardboard pallets that are robust, 100 per cent recyclable, nestable and reusable. They also enable cost savings along the supply chain in many applications. Adhesive application technology from Baumer hhs is used in the special machine for the automatic production of the pallets.

„More than 15 years ago, my father recognised the advantages that pallets made of corrugated cardboard could offer,“ explains Perry Sommer, Managing Partner of Cone Pal Vertriebsgesellschaft GmbH. The breakthrough began when Sommer was given the opportunity to develop his father Dietmar's idea into a solution as part of a project with a large company in the food industry, which could also be used in the food industry. Suitable for demanding logistical requirements is. The following year, a first machine was installed for the automatic production of the innovative pallets. This was quickly utilised to capacity, which is why the company put a second machine into operation in late summer 2022 - one that is unique in the world, Largely customised machine developed in-house. Adhesive application technology from Baumer hhs plays a decisive role here.

Two-shot gluing

Cone Pal also developed the adhesive application in the base erector itself. The three differently sized feet of the pallets consist of sophisticated die-cut blanks made of sturdy corrugated cardboard, which require a special folding and gluing process. This task is performed by the automated foot erector. The unique The company has patented the anchoring of the feet to the top layer of the pallets. Together, the sophisticated design, the material and the adhesive application guarantee the enormous stability and robustness of the feet - and therefore of the pallets. This means they can also carry heavy goods such as drinks and spirits in logistics processes.

After discussions with various providers of adhesive application systems, the decision was made in spring 2022 in favour of working with Baumer hhs. Two-shot bonding would be used in the foot erection a combination of hot melt and cold glue application - best fulfil the requirements of Cone Pal. Depending on the size, the pallets have six or nine feet. The three sizes of feet can be explained by the fact that different industrial sectors have different requirements in terms of the underrun capability of their pallets. In terms of load-bearing capacity, there is practically no difference between the large and small feet. The adhesive application technology from Baumer hhs offers every flexibility in the production of feet of different sizes.

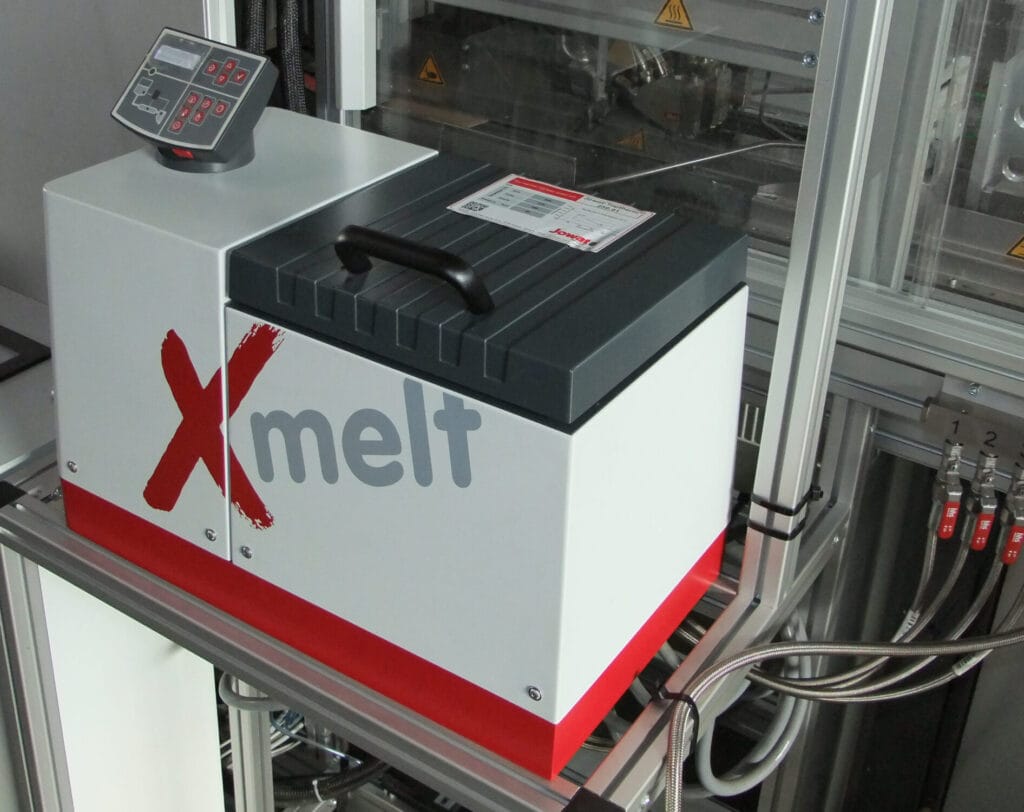

Their price-performance ratio is also ideal for this price-sensitive application. With the HM-500 and the DLK go, the choice fell on reliable and cost-effective hot melt and cold glue valves. The Xmelt melter and the reliable cold glue feed unit are also standard products that have proven themselves in countless installations for Baumer hhs customers worldwide. In addition, Cone Pal Apply the exact amount of adhesive required, which perfects the adhesive application. The minimised adhesive consumption also benefits the sustainability of the already environmentally friendly pallets.

Practically customisable at will

If required, Cone Pal can customise the pallet designs flexibly. For example, they can be printed and coated with anti-slip varnish or additional impregnation protection at the customer's request. The Cone Pal product family currently comprises seven standard sizes, which are constantly meeting the new requirements of more than 500 customers. An adhesive application system from Baumer hhs is now also used at the company's second production site in Kevelaer. „Basically, we can produce pallets worldwide and just-in-time on site at the customer's premises,“ says Perry Sommer, outlining the potential of the market. „That's why the scalability of Baumer hhs technology is important to us.“ The company supplies the majority of its production to other European countries. But also to overseas markets such as Argentina and New Zealand.

„40 of our pallets can be stacked on top of each other. They are also 3.5 cm lower and considerably lighter than conventional wooden or plastic pallets. This means that our customers save a lot of money on transport and reduce their environmental impact. Fully loaded lorries that use our pallets instead of wooden pallets transport around 700 kg less weight for this reason alone.“

Perry Sommer, Managing Partner of Cone Pal

Source: Cone Pal