How can products in a wide variety of shapes, materials and performance levels be labelled today and integrated into complex track & trace processes? This is possible with innovative labelling technology, high-resolution cameras and the connecting KUPvision software as a special solution.

For Stefan Klöpping, the Managing Director of Intrex Deutschland GmbH, the secure allocation and traceability of packaging materials is one of the core issues that manufacturers of pharmaceuticals and medical products have to deal with on a daily basis. For example, in the production process of an international pharmaceutical company, the Reliable allocation and traceability of cylinder ampoules and vials by Data matrix coding on the crimp caps be realised.

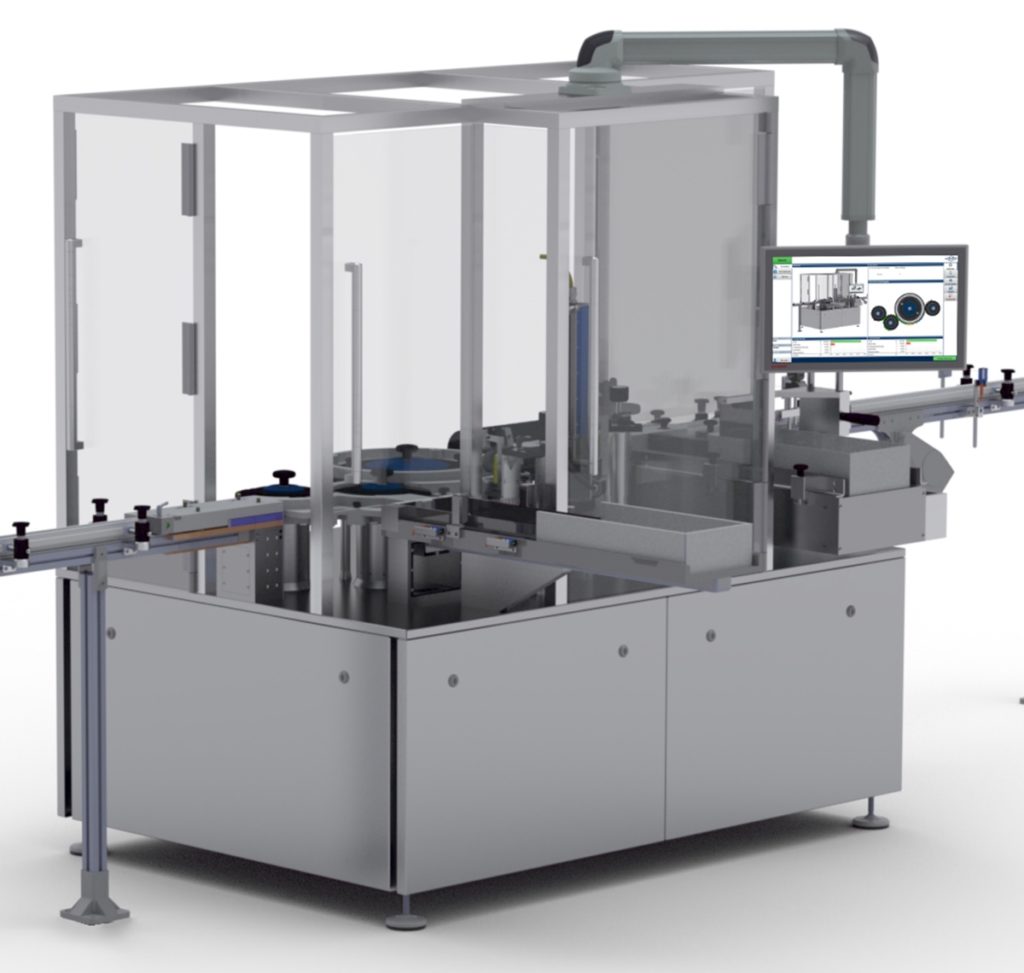

This is made possible by the use of the Intrex conveyor system type ITX-AMV in combination with the Domino fibre laser F220i and a 360-degree ID reading system, which was also developed by Intrex Germany.

Data matrix coding: Product flow and labelling

For feeding into the marking station there are Two variantseither automatically on an existing conveyor belt or manually via a separate infeed table. There, the ampoules are removed from trays by hand and fed into the machine infeed.

The coding in the station is carried out with a marking laser on the side of the crimp caps and contains the product and batch number, the current time and a consecutive number. A serial number assigned on the line or by the ERP system is also possible as an option.

The markings are checked in the machine with a camera and graded (AIM-DPM). This ensures Precise identification across all process steps ensured.

The 360-degree ID reading system

Later in the production process, the labelled ampoules pass through this ID reading system. Six Cognex DataMan readers arranged in a circle check the data matrix codes for readability. Depending on the result, the products are either classified as „GOOD“ and pass on to the next process step, otherwise they are rejected.

[infotext icon]Data matrix coding: Performance data at a glance

- The design and construction comply with the EC Machinery Directive 2006/42/EC, EU GMP, GAMP 5 and also fulfil FDA requirements (e.g. 21 CFR Part 11).

- Over 400 labels with product and batch number, time and consecutive number per minute

- Serialisation data can also be integrated into the marking as an option

- Gentle product vacuum transport

- Quick changeover to other vial and ampoule formats

- Domino F220i fibre laser with the latest fibre technology as a marking source

- Read-back possible later in the production process with an Intrex 360-degree ID reading system. [/infotext]

Software centrepiece

KUPvision is the application software for complete system management, the Domino laser coder and the 360-degree ID reading system. It transmits both batch information and inspection parameters to the cameras and the laser: and it receives their analyses via an Ethernet connection. Information such as user logins, job and format changes are stored in a computer-generated audit trail.

The date, time, user, function data and parameters are saved for each entry. Audit trail and statistical data can be called up at any time. The required user rights are regulated by a user administration system. Test results and system statuses are displayed on an industrial PC with touch monitor, which can optionally be linked to the filling machine. All machine inputs and operation of the Domino laser can be controlled centrally via this HMI.