At Anuga FoodTec, Heuft will be showcasing the further development of its X-ray system for inspecting unpackaged product masses. Artificial intelligence is used for image processing.

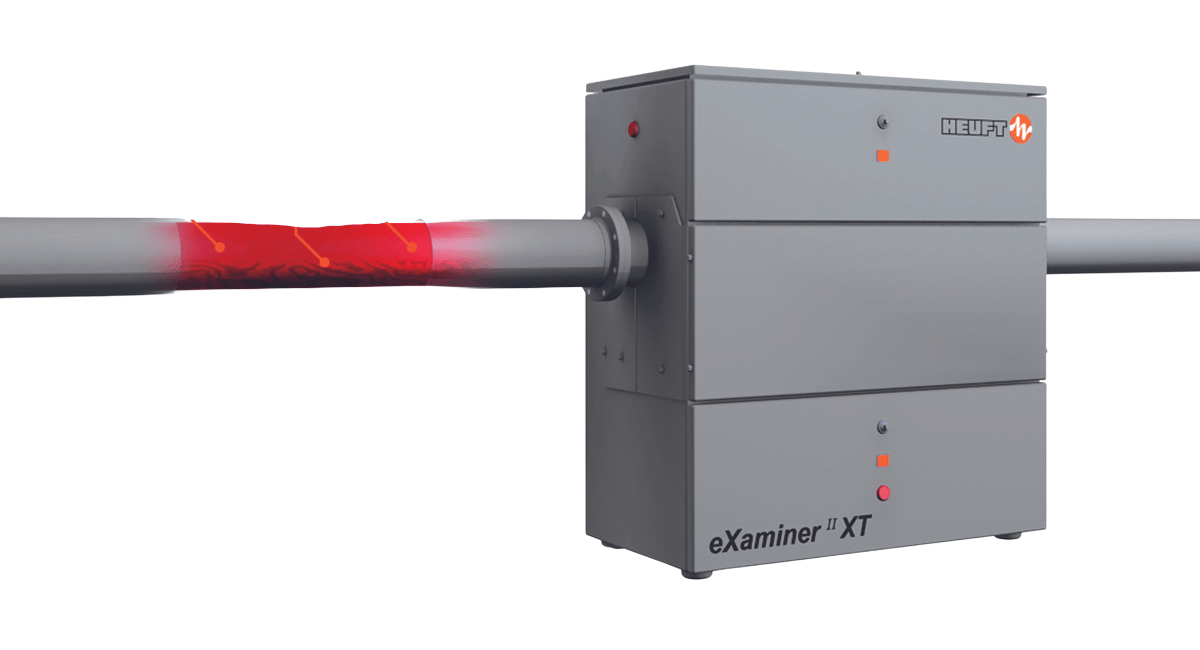

The latest version of our Heuft eXaminer II XT for pipework inspection now offers even more performance and flexibility. With further developed generators and full-field image converters, the pulsed X-ray covers larger areas than before. The millisecond X-ray flashes penetrate product masses such as sausage meat, jam, yoghurt, syrup or even creams and toothpaste in even larger pipe dimensions of up to 150 DN in order to detect metal particles, glass particles, stones and other Identify high-density foreign bodies even before the actual filling and packaging process.

Even if the transport speed within the pipeline is extremely high or fluctuates, the X-ray technology developed and manufactured in-house ensures clear detection images with minimal radiation and no motion blurring. Smart filter, classification and teach-in processes as well as innovative Deep learning functions for real-time image processing with Heuft reflexx A.I. help to reliably distinguish real risks from product inhomogeneities and other harmless deviations. This ensures that only goods that are really no longer marketable are withdrawn from circulation and that no food is wasted. A rejection valve is activated directly for this purpose.

The compact Heuft eXaminer II XT offers greater flexibility for integration and installation thanks to its completely redesigned, modular construction. X-ray generators and receivers, the product-conducting tube, the device housing and the control terminal with self-explanatory Heuft NaVi user guidance can be positioned almost anywhere. Unlike conventional pipework inspectors, this means that A wide range of installation positions can be realised - up to wall and ceiling mounting.

Fully automatic and without the need for time-consuming recalibration, type and programme changes are possible. This also applies to regular self-tests to check the detection performance in an innovative process: Up to four carbon fibre fingers prepared with different test objects are moved directly into the beam path for this purpose, so that the Detection reliability tested under real production conditions and fully documented can be realised.

Source: Heuft

Heuft at Anuga FoodTec: Hall 5.2, Stand B-0303 C-031