A development competition could not be more compact. Over two days, students and young professionals met in the Swabian Packaging Valley for the so-called Makeathon. At various locations, they worked on solutions for digitalisation and sustainability in packaging machine construction. They also came up with ideas for smarter packaging.

Smart food packaging

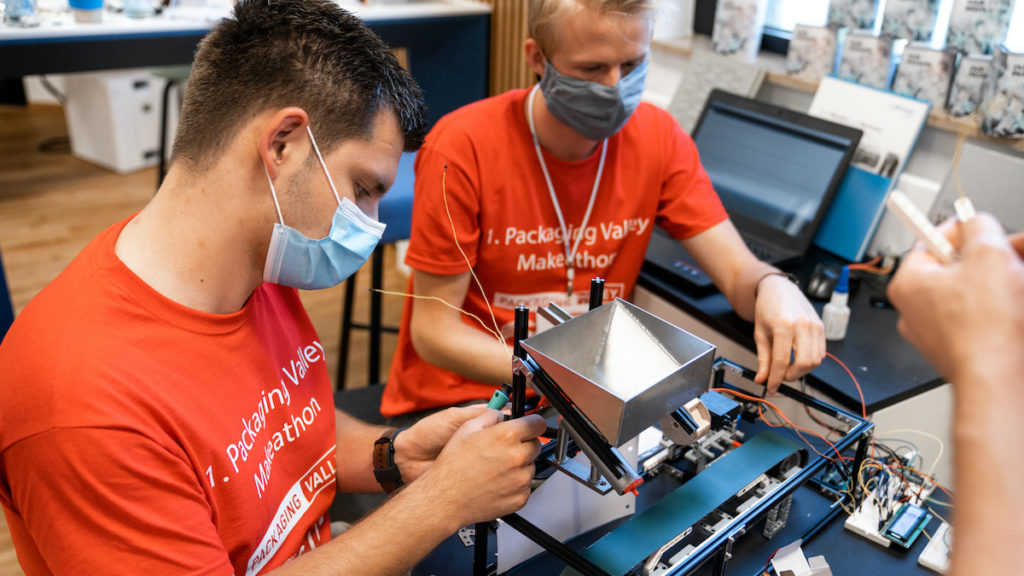

One of the venues was the headquarters of machine manufacturer Optima. There, in the new Digital Innovation Centre, the participants developed three solutions for a Sustainable circular economy and environmentally friendly packaging. One idea: A dynamic tag as a replacement for the conventional barcode on food packaging. It informs retailers and consumers about stock levels and can provide early warning before fruit or vegetables go bad.

Reusable with built-in chip

Another idea was Standardised reusable packaging with integrated data chips, which are produced and reprocessed centrally. These promise logistical advantages, enable centralised recycling and create transparency about stock levels thanks to the integrated data storage system. „fully automated unpacked shop“. After entering a desired weight, the dispenser doses bulk goods such as coffee beans into reusable containers.

Projects for environmentally friendly packaging to be expanded

As further steps, the participants are planning market analyses and the Initiation of intensive cooperation with all companies involved in the value chain - from packaging machine manufacturers to food companies. They want to further expand their projects and Integrate into the circular economy in the long term.

Source: OPTIMA