The European Tube Manufactures Association (etma) met in Prague for its annual conference and announced the winners of the Tube of the Year 2022 competition. The jury selected the winners in the categories of aluminium, plastic and laminate tubes as well as prototypes and sustainability.

With its annual Tube of the Year competition, the etma every year anew the Creativity, innovative strength and performance of the European tube industry. Beyond the borders of Europe, the award sets global standards for pioneering and sustainable packaging solutions of the highest quality.

To the The jury chose the Chanel N°5 tubes as the winner in the aluminium tubes category produced by Tubex Aluminium Tubes. To mark the 100th anniversary of Chanel N°5, the legendary brand has launched a limited edition of selected products: the Chanel Factory 5 Collection with gels and lotions, packaged in a functional design of a special kind - in oil cans and colour pots, all printed with the iconic black and white design. The winning tubes from Tubex Aluminium Tubes were used as packaging for La Crème Corps (150 ml and 20 ml) and Le Gel Douche (20 ml). All three tubes were labelled with a matt outer lacquer over the tube body and shoulder and with a white, octagonal cap manufactured.

Plastic tube clears twice

There were two winners this year in the Category Plastic tubes. Firstly, the Caudalie shower gel tube, which is manufactured by Albéa, took first place. Caudalie has opted for a new packaging solution for its iconic shower gel line. This combines a Beautiful colour shading achieved with mass ink and flexographic printing with a colour-coordinated cap. The tubes utilise Albéa's Thin-Wall COEX PCR Max technology in combination with the Slight Cap PP for a Lightweight tube with high PCR content.

The other winner in the plastic tube category is produced by the Swiss manufacturer Hoffmann Neopac produced. For a vegan toothpaste from Liebherr, Neopac has specially developed the PICEA tube with spruce wood content created. This „wooden tube“ is a high-quality packaging solution that emphasises the naturalness and sustainability of the product. You can really feel the difference, as the fine wood flour makes the surface of the tube feel slightly rough.

The tube has a significantly improved eco-balance thanks to the material used, as the PICEA wood tube is made of over 95 per cent from renewable resources - The proportion of spruce wood is 10 per cent, the sugar-based proportion is 85 per cent. The processed spruce wood originates from certified forests in the EU. The wood fibres come from sawdust waste from German joineries. The PICEA wood tube scores highly with its over 40 per cent better CO2-balance compared to a conventional PE tube. At the same time, it offers the same qualitative properties in terms of barrier function, decoration, food suitability or recyclability.

Winner in the laminate tube category

With the Laminate tubes was occupied by the company Albéa The new Lipikar Baume AP+M tube, produced by La Roche-Posay, took first place. The new Lipikar Baume AP+M is now available in a environmentally friendly tube available and uses Albéa's EcoFusion Top, a unique solution that enables a weight reduction of 80 per cent (compared to standard head and cap), combined with Metamorphosis, a paper-based solution that uses 60 per cent less plastic than the previous Lipikar packaging. contains. EcoFusion Top is made from HDPE to ensure mono-materiality and recyclability.

Prototype with reduced CO2 emissions

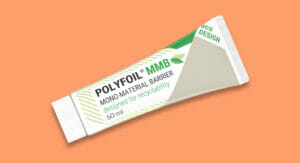

With the award-winning and patented MMB tube technology, Hoffmann Neopac convinced the jury at the Prototypes and was the winner in this category. The Polyfoil MMB monomaterial barrier tube is characterised by its Combination of high product protection, a minimum amount of non-PP materials, user-friendliness and appealing aesthetics and represents a significant advance in environmentally conscious material technology. The PP-based Polyfoil MMB tube with PP closure or applicator can be recycled in the PP container recycling stream in accordance with RecyClass product approval and is also well suited for oxygen-sensitive goods. Compared to the conventional standard Polyfoil range, Hoffmann Neopac uses less plastic in the tube body, which reduces CO2 -output of a tube with a diameter of 30 mm by up to 40 per cent.

Winner in the category Sustainability The plastic tube „Tube 4.0“, which was developed by the German manufacturer Linhardt is produced for its customer dm. As part of the „Tube 4.0“ project, the Wall thickness of the plastic tubes of the dm brands Balea, Balea MEN, alverde, SauBär, babylove and Jessa reduced by 30 per cent from 0.50 mm to just 0.35 mm. The proportion of recycled plastic has also been significantly increased: Instead of 50 per cent as before, the new tubes now contain 60 per cent (Coex) or 70 per cent (Mono) post-consumer recyclate (without cap). Thanks to this combination of a higher proportion of PCR and lower material usage reduces the consumption of primary material. The conversion saves 2.9 g of primary plastic per tube for the submitted 200 ml winning tube of alverde „Ultra Sensitive Care Shower“. Despite the high PCR content, the tubes are characterised by a pleasant white tone and an attractive print image using Linhardt's own HD printing process. Increasing the PCR content while reducing the wall thickness and maintaining the attractive appearance is technically demanding and represents an important step towards more conscious use of raw materials.

Source: etma

More news about tubes

New monomaterial tube ensures personalised cosmetic dosing

These are the winners of the „Tube of the Year Award 2024“

Hoffmann Neopac presents paper tube

Recycled aluminium in packaging - sensible, honest, responsible?