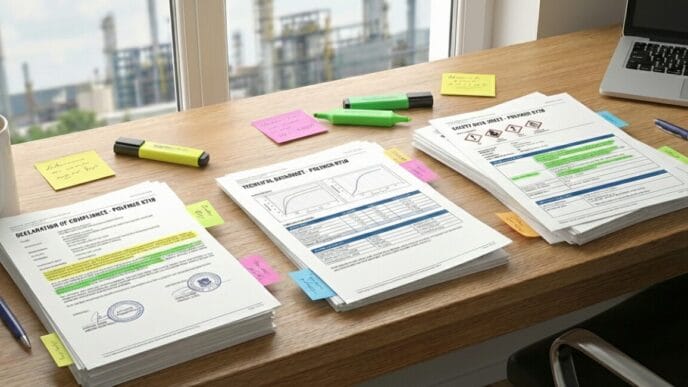

Conventional flour packaging is not sealed dust-tight so that the product can escape. This can only be remedied with dust-tight packaging. The Roland Mills United milling group, for example, relies on a new line solution from Syntegon that packs flour in high-quality, sustainable and, above all, dust-tight packaging.

When you reach for the usual flour packaging in the supermarket, a small amount of the product is stirred up. Fine flour dust already covers the pallet and inevitably finds its way into the shopping bag, the car boot and ultimately into your own kitchen. Consumers are familiar with this situation.

According to Matthias Karrenbauer, Head of Production and Technology at Roland Mills United Dust-tight flour packaging Advantages that are worth investing in. „This packaging is particularly high-quality and is therefore ideal for premium retailers - a market segment with future potential for us.“ Roland Mills United is a modern family business spanning several generations with milling sites in Bremen, Recklinghausen, Bad Langensalza and Münster and is one of the leading flour mills in Europe. A total of more than one million tonnes of flour are milled each year at four locations in Germany.

The company combines the Expertise of its milling tradition with the passion, to develop further for the future and seize opportunities arising from the changing procurement and sales markets. When Roland Mills United decided to replace one of the packaging machines in Recklinghausen after 40 years of operation, the demands on the new filling machine were correspondingly high.

„Our aim was to find a future-proof line solution that combines sustainable primary and secondary packaging. It also had to fit into a limited space. Overall, Syntegon provided us with the optimal technical solution and gave us the best feeling: we opted for their Package Maker PME 4081 BS and the Elematic 3001 WAH case packer to pack our dust-tight flour packages in high-quality cardboard trays.“

Innovative sealing technology

To produce conventional flour packaging, paper is glued, formed into a bag and then simply folded to seal it after filling. As the glue dries quickly, the bag production process can only take a few seconds before its adhesive properties deteriorate. This disadvantage does not apply to the dust-tight flour packaging, which is sealed with Significantly less sealing medium without. In the Package Maker PME 4081 BS from Syntegon the innovative, specially developed module takes over the first steps of production. A roll feeds uncoated paper to the ZAP module. In the module itself 14 time-controlled nozzles carry the sealing medium in only three areas on the later base of the packaging as well as on the top and the longitudinal seam. The rest of the material remains untreated so that the packaging continues to allow moisture exchange and contributes to the longer shelf life of the flour.

Since the sealing medium is only applied selectively, the Packaging material still contains over 95 per cent fibrel and can be easily recycled as a mono-material via the waste paper stream. There is also no time pressure with this method, as the sealing medium dries immediately after application and is only thermally reactivated later in the process.

The PME 4081 BS folds the bags by means of a mandrel wheel before two screw feeders with integrated suction stations fold each package one after the other. Fill individually in two stages to reduce dust formation. Each filled flour bag is then shaken on the closing chain for around ten seconds to fully compact the flour. Finally, thermal sealing jaws seal the bags to produce robust, dust-tight and compact flour packaging.

High machine efficiency

The Package Maker PME 4081 BS packs around 80 tonnes of flour per day in two-shift operation. The innovative sealing method contributes significantly to the efficiency of the machine: After a machine standstill, such as during a paper roll change, empty or filled flour bags can continue to be sealed as usual. The Sealing medium is heated and activated by the sealing jaws during sealing. With conventionally glued packaging, the adhesive dries out during downtime, meaning that all bags in the machine at the time have to be disposed of.

The machine's special clean concept also provides further efficiency benefits during operation: The machine's bag conveyor belt is inclined by around 45 degrees. In the event that an already filled bag tears, the flour does not fall into the machine room and contaminate the equipment, but can be collected outside the machine in the collecting chute.

„The downtimes of our solution are reduced to a minimum. Apart from brief interruptions for cleaning and paper changes, the machine can produce continuously, enabling us to achieve a machine efficiency of 97 per cent. Comparable solutions from other manufacturers often achieve a maximum of 75 per cent.“

Uwe Pfander, Senior Sales Manager at Syntegon

Great packaging flexibility

In addition to the high machine availability, the experts at Roland Mills United were also impressed by the packaging flexibility. „Thanks to extensive test runs in advance, we know that we will be able to use the machine Process papers from multiple suppliers can. This is an important competitive advantage for us,“ explains Karrenbauer. „When the Ukraine crisis broke out, there was a shortage of flour in the supermarkets - but not because there was a lack of product. We simply ran out of paper for packaging. At the time, we were one of the last milling companies still able to deliver, as we had enough packaging materials from various manufacturers in stock. With our new machine, it was therefore important for us not to be dependent on one supplier, but to be able to continue to offer a wide range of packaging materials in the future. Use different packaging materials to be able to.“

„These paper tests were also a benefit for us, as we were now able to confirm not only in theory but also on the machine that our ZAP module is compatible with paper from several suppliers. With the material tests in our Pack Lab in Waiblingen, we were able to analyse the exact properties and dimensions of the papers and provide Roland Mills with comprehensive documentation. We were also able to make recommendations on precise machine adjustments and machine parameters to ensure optimum performance of the PME during operation.“

Uwe Pfander

High-quality primary and secondary packaging

Roland Mills United not only drew valuable conclusions from the paper tests in terms of machine suitability. The test runs also helped with the high-quality design of the final packaging. As the Packing material peelable Roland Mills added a grip end to the flour bag for even more user convenience. Consumers can now open the packaging without having to reach for scissors.

For Roland Mills United, it was clear from the outset that the Secondary packaging of the products must not be inferior to the primary packaging in terms of value was allowed to do so. „In order to be able to offer our dust-tight flour bags in premium retail, we invested in a Syntegon case packer that packs them in a display carton. This enables us to achieve a high-quality appearance that appeals to customers at the PoS and attractively showcases our own brands in particular,“ explains Karrenbauer. The Elematic 3001 WAH from Syntegon packs 100 flour packs per minute with minimal adhesive consumption. When folding the display cartons, the adhesive is only applied selectively so that the secondary packaging can also be easily disposed of with the waste paper.

Cooperation at eye level

„We are very satisfied with the result of this collaboration. Both Mr Pfander and I have been in our business for a long time - our discussions were always constructive, so we made rapid progress. As a rule, milling machines can remain in operation for up to 40 years. We are confident that with Syntegon's equipment, we have chosen a future-proof solution that will produce high-quality products for decades to come.“

Matthias Karrenbauer