The name HSV Sondermaschinenbau GmbH is synonymous worldwide with technology-leading packaging systems in the segment of highly viscous or reactive filling goods. In a filling line for car windscreen adhesives, Herma 500 labellers guarantee high precision and reproducibility despite different containers and label variants.

Extreme precision and maximum process reliability are required when Highly viscous or reactive products such as two-component adhesives and moulding compounds for dental applications are filled and packaged. To prevent an unwanted reaction such as premature curing, there must be no inclusions of ambient air.

„Our filling and packaging systems are highly automated for this reason alone. We try to eliminate the human factor as much as possible, not least because batch sizes are getting smaller and changeover processes are increasing.“

Waldemar Hert, Managing Director at HSV Sondermaschinenbau

As a general contractor, the company develops and manufactures complete systems to a high standard of perfection, from the removal of the filling goods from drums to the finished pallet with the packaged containers such as cartridges. Such systems can have dimensions of more than 200 square metres. Renowned manufacturers on almost every continent rely on the cutting-edge technology from Asperg in Württemberg.

Interface as a challenge

HSV is correspondingly demanding when selecting its suppliers. For labellers, the company now relies exclusively on the Herma 500. the presence of the Profinet interface“, the HSV Managing Director emphasises one of the reasons. „This allows us to fully integrate the labeller into our own control architecture. All parameters then come from the process control system, and these are automatically adopted by every integrated component of the packaging system.“

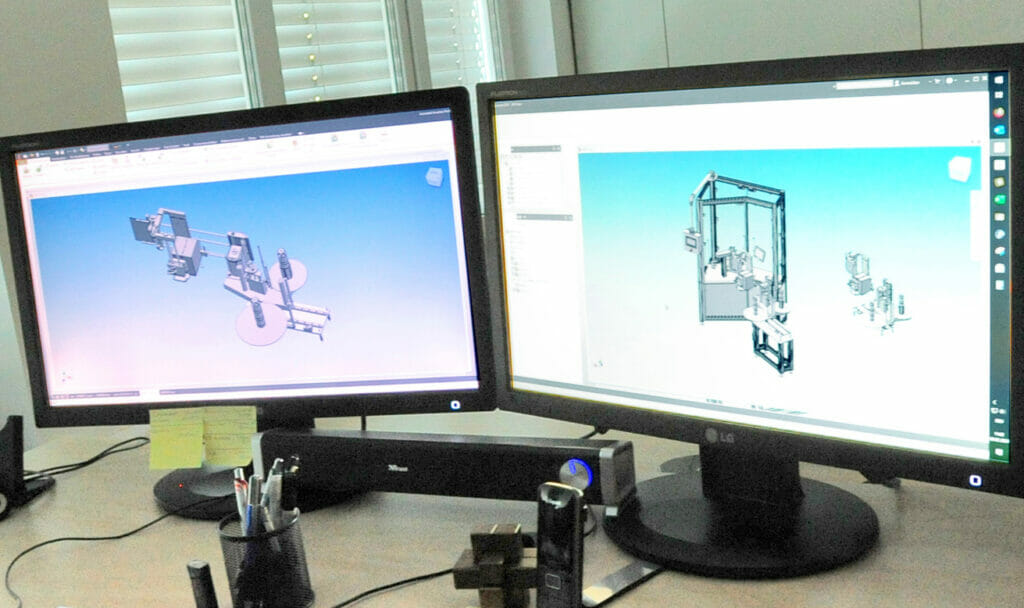

The flow of data is particularly important for a special machine manufacturer that is constantly faced with new requirements: „It is extremely helpful for us, data in any form, whether this concerns the control technology or CAD models. A cheaper labeller is of no use to us if we then have to spend weeks modelling it in CAD or creating EPLAN macros.“ The online configurator that Herma has developed is therefore also a decisive advantage.

„We can use it to preconfigure the labeller and stand as we need it. We then create a CAD model there, download it and use the data in our own CAD system. After 15 to 30 minutes, we have an individually configured labeller including the CAD model and can enter it into our design. Without such a configurator, it would sometimes take weeks before we could continue working on customised solutions. The finished labellers are ready for installation after around four weeks.“

Jörg Leonberger, HSV Operations Manager

This speed is also due to the modular design of the labeller. The same basic unit can be configured for any speed, any installation situation and any dispensing variant. This ensures standardised and therefore reliable series production as well as rapid availability and consistent integration processes at all times.

Sophisticated containers, high labelling variability

Labelling containers with special adhesives for the automotive sector presents numerous challenges: the latest HSV system, in which two Herma 500s were installed, is used to fill a special adhesive that is used to attach windscreens to cars. This system is operated in North America. The containers consist of 20 product variants, which are filled into both plastic and aluminium cartridges. A large number of label variants are also used, some in the form of booklet labels.

„The variety is a major challenge for the labelling process,“ emphasises Waldemar Hert. „The aluminium cartridges remain nicely cylindrical after filling, but the plastic cartridges become slightly conical or spherical.“ The labeller nevertheless ensures for high reproducibility of precise and crease-free labelling results. „There is no slippage with the Herma 500 and the scanning is perfect,“ summarises the HSV Managing Director.

If new labelling conditions arise during operation, this is no problem with this technology. You can Remote access to all parameters via web interface. What the operator sees on the smartphone-sized touch display of his labeller can also be seen by the HSV technicians in Asperg via a web-enabled end device. „In consultation with the operator, we can then click through the menus and specifically increase or reduce the value of a parameter,“ says Waldemar Hert. The reason is simple: „If we were to do something in the background that the operator didn't realise, he wouldn't be able to understand it. But this way he understands the context and can deal better with an irregularity in future.“

Herma - More news

Marcus Nickel is responsible for sales for the entire Herma label sector

HERMA presents sustainable labelling solutions without compromise

Herma Managing Director Sven Schneller announces retirement for 2026

That was the cycle & circle sustainability tour 2025