The mechanical engineering company Ishida is causing a stir on the packaging market with three new models. The three new machines serve both the filling and food safety sectors.

It's not every day that a company launches several new models on the market at the same time. The mechanical engineering company Ishida did just that and presented it to the public on 19 October. Three new machines for packaging companies.

Optimum feed monitoring

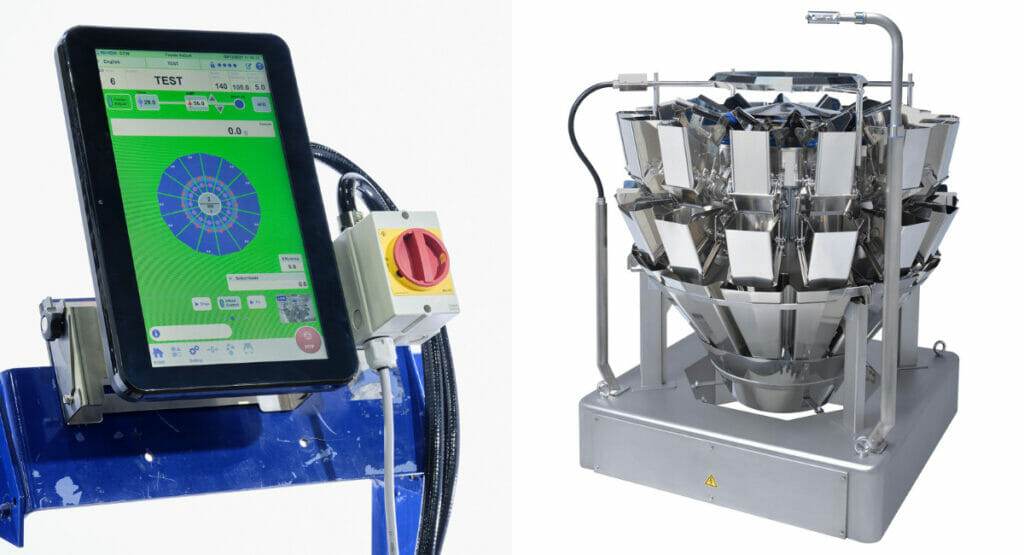

The Japanese company's flagship product is certainly its wide range of multihead weighers. The company has been selling these devices in various sizes for 50 years. Ishida is now launching the 11th model generation on the market with the CCW-AS series. The multihead weigher enables industrial users to significantly increase productivity.

One performance-enhancing feature of the 32-head multihead weigher is the optimised product transport to the weighing trays. The increased control and performance of all feed chutes can be an advantage in high-performance applications or when processing sticky products. In addition, each feed chute has an integrated optical control system that uses sensors to monitor the product depth in real time. This means that both the feed amplitude and the feed time can be set independently on each vibrator in order to always feed the right amount of product to the weighing trays.

In addition, an optical monitoring system with several cameras can be installed on the top of the scale. The live images of the product feed are then displayed on the 16-inch colour touchscreen HMI operating screen.

Many packaging materials, consistent seal quality

Once the product has been weighed, it usually also needs to be filled. Ishida has designed the Inspira Box Motion flow-wrapping machine for the snack sector. It can operate in both continuous and intermittent mode. According to the company, this enables the processing of a wide range of product and packaging formats, including recyclable film and paper packaging, while maintaining seal quality and integrity.

The Box Motion technology enables the sealing jaws to move both in the vertical and horizontal inlet and outlet levels. This means that a uniform pressure is exerted over the entire surface of the jaws and thus a more even and reliable seal is achieved.

Other advantages of the machine include a light bar for the splicing table, conversion without replacing components and, according to the company, a Energy savings of 17 per cent in operation and 25 per cent in standby mode compared to the previous model.

Improved detection rate

Ishida also has a new addition to its portfolio in the area of food safety. The IX-PD X-ray inspection system is capable of both Foreign bodies with low density as well as very small impurities to be recognised. In addition, foreign bodies are identified in products that overlap or stand upright in the packaging.

According to the company, the device has demonstrated an almost 100 per cent detection rate for bones in a variety of meat and poultry products in tests. For example, an increase from 40 per cent to 100 per cent was achieved in the detection of bones in chicken breast fillets compared to existing X-ray inspection technologies.

Ishida developed IX-PD for use in high-performance production lines and for applications where products can overlap in tight packaging, making it difficult to detect small contaminants. The performance of the IX-PD minimises the need for manual inspections. The device's ability to distinguish between food and foreign bodies with high accuracy reduces false rejects. In this way, companies can provide stringent quality control without compromising on throughput rates.

Source: Ishida

More news about packaging technology

Sustainability as a driver of innovation in cosmetics packaging

Refresco uses laser technology for lighter PET bottles

Efficient logistics on five wheels

Herrmann Ultraschall appoints Jörg Zech as COO