The packaging industry also continues to suffer from a shortage of raw materials and supply bottlenecks. This is compounded by a shortage of skilled labour, which is unlikely to disappear in the medium term. One solution that SMEs and smaller companies can use to counter this problem is to outsource the assembly and packaging process to specialised service providers. This is what the Leipzig-based company Nucao has done and now has its Advent calendars packaged by Karl Knauer KG.

The market for important raw materials has been swept clean and supply chains that have functioned smoothly for many years have been disrupted. And it's not just the automotive and electrical industries that are affected; the packaging industry is also struggling with supply disruptions and material shortages. This is why the Federal Association of the German Confectionery Industry (BDSI) warned at the beginning of the year that this could potentially have an impact on the Easter business. There was a risk that not all chocolate bunnies or Easter items could be produced or packaged as planned.

For the upcoming Christmas business with a focus on individually filled Advent calendars, it is also important to plan early to ensure the availability of materials and bridge bottlenecks. Packaging specialists such as Karl Knauer KG from Biberach/Baden, which offers co-packing services in addition to packaging production, are well aware of this.

The entire supply chain must function smoothly and all raw materials and supplies must be available to ensure that the goods are actually packaged safely and arrive at the retailer or customer on time. This is becoming increasingly difficult due to the current pandemic and crisis situation in the globalised world. This is why more and more companies are outsourcing the entire packaging process for orders with a fixed delivery date, from the production and provision of packaging to the packing of goods and order picking, to reliable partners with short response and delivery routes and contact persons who are available at all times.

Packaging, QA, intermediate storage from a single source

Packaging producers and specialists who, like Karl Knauer KG, cover all sectors from pharmaceuticals to food and beauty and have experience in handling large-scale projects with millions of individual parts, are realising how important trust between customer and service provider is at this time. "We are delighted that, in addition to our existing customers, we are gaining more and more new customers in the contract packaging sector", says Tobias Munz, Key Account Manager at Karl Knauer. "In addition to large, well-known brand companies, for whom we often take on the accompanying services such as incoming goods and quality control, inventory monitoring or interim storage of the goods in addition to the packaging itself, we are also approached by smaller companies and numerous start-ups. Everything from a single source also has the advantage that the topic of co-packing is already taken into account at the start of the project during the development of the packaging."

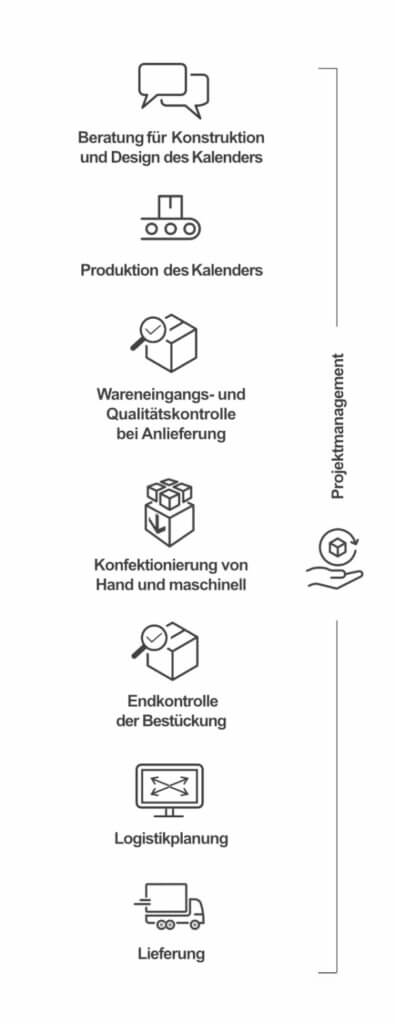

Advent calendars are a good example to describe the complete scope of a packaging process. This is because they often consist of dozens of components that have to be put together to form a convincing package. This starts with the choice of materials for the calendar and its design, includes the correct storage of the products that are to wait to be discovered behind the right door, and does not end with the punctual delivery.

It is therefore not surprising that Karl Knauer's Advent calendar development and production is in full swing long before Easter.

The collaboration with the young team has worked so well that there are already follow-up orders. "This year, customers can once again look forward to creative, particularly sustainable Christmas specials from this provider. Unfortunately, we can't reveal any more yet," says Tobias Munz, looking ahead to the 2022 Advent season.

Not only start-ups like Nucao, but also numerous brand companies value experienced experts when it comes to unusual packaging projects. Because they know exactly which adjustments can and must be made in order to get the product to the customer as efficiently, economically, sustainably, safely and punctually as possible. And that pays off now more than ever.

More news on the topic of co-packing

Packservice: The automation of packaging

Com.pack.t offers contract filling for start-ups

Creative packaging with contour: sachets made from mono material

Flexible contract filling of adhesives and sealants at Gluetec