Film manufacturer Duo Plast wanted to work more effectively in field service management. To achieve this, workflows and processes had to be clearly summarised in a tool so that the scheduling department also had an overview. In the end, the choice fell on a system from mobile function.

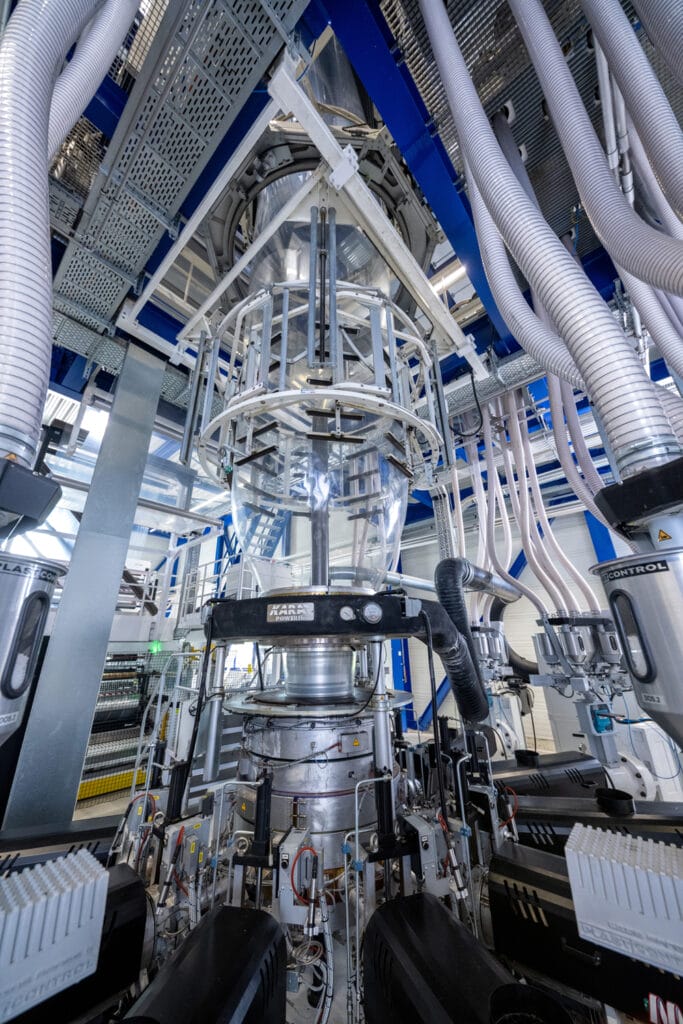

The Duo Plast AG is a manufacturer of stretch films and was founded in 1983 as a trading company. Today, the company manufactures blown film in its own production facilities and in patented processes at two locations. The Duo Systems division uses the ENGINE4.SERVICE solution with the ENGINE4.CHECKLISTS and ENGINE4.TIMES extensions from mobile function GmbH in Villingen-Schwenningen.

Previously, service technicians travelled with pen and paper. Service reports were filled out by hand at the customer's premises. That cost a lot Time and the paper chase with various forms and logs was confusing. In the office, the fitters' paper forms and reports were scanned and assigned properties so that they could then be filed in the project file.

Duo Systems used a self-programmed solution in the CRM system to plan service calls. The decisive factor in the search for a new tool was the Desire for digitalisation and process optimisation. The aim was to streamline the processes for the service technicians as well as for the customers and the office staff. The new tool for the field service should Increase the degree of automation and make work easier for everyone bring.

Duo Systems held talks with various companies. In dialogue with mobile function, it quickly became clear that the field service management software specialists were familiar with the challenges faced by technical field service. „We were immediately shown solutions,“ says Kai Stocklöw, Deputy Director of Duo Systems.

The collaboration began in September 2022 with a hackathon: consultants from mobile function worked with Duo Systems to specify the requirements, the status quo and the objectives and presented a broad, customised solution at the end of the three days. Internal tests were carried out at Duo Systems for some time, followed by the go-live of ENGINE4.SERVICE in June. One For a month, the new system ran in parallel with the old one, to have a backup solution to hand in an emergency. Since July, only ENGINE4.SERVICE has been used for service calls.

The implementation was closely supported by the IT department. The app interface was adapted to the needs of Duo Systems with new buttons and modified menu navigation.

„When things got a bit trickier, we called the support team. They solved our problems quickly and smartly. We are very satisfied with the course of the project and the solution. The tool works, our technicians quickly got used to it and gave us positive feedback.“

Kai Stocklöw

With ENGINE4.SERVICE, Duo Systems now handles All orders and service planning for the technicians from. The customer order is created in the ERP and in ENGINE4.SERVICE. Necessary parts are scheduled or ordered and the route is planned. With ENGINE4.SERVICE, the customers are now visible on a digital map and the Dispatcher immediately has everything in view. Once the appointment has been agreed with the customer, the order is sent to the service technicians via the app. They can then process it and record activities, working and travelling time or spare parts.

The ENGINE4.CHECKLISTS add-on also stores maintenance logs and lists for UVV inspections. ENGINGE4.TIMES works like a digital stopwatch and helps technicians to record working and travelling times more conveniently. Finally, the customer signs the work report digitally and the technician can send it to him immediately by e-mail.

With the tools from mobile function, the Reduced paper requirements in the officeTechnicians no longer need to carry forms with them. Order processing at the customer's premises is faster, and reports can be completed quickly using text modules and digital forms. Stocklöw sees the main simplification in the digital document storageLogs and service reports are automatically collated here and stored as PDF files in the document management system, work that previously had to be done manually.

Duo Systems would now like to have a function that allows technicians to record the spare parts they install directly in the system using the camera. Currently, it is still necessary to enter the numbers manually so that the spare part can then be automatically assigned by the tool in the assembly report. In the future, time recording could also be fully mapped using the mobile function tool.

Source: mobile function

More news on automation

Solutions for intelligent order processing

Dortmund becomes the meeting place for packaging and intralogistics

White paper | How to make packaging machines more dynamic through lightweight construction

Powerful automation for mills