The newly formed Curing business unit of Dr Hönle AG consists of the printing specialists Hönle, Eltosch Grafix, PrintConcept and GEPA Coating Solutions. It stands for highly efficient customised curing and drying solutions in printing applications.

Its extensive product portfolio includes LED UV as well as conventional UV, inert UV and IR systems and enables individual, customised solutions for every printing application and guarantees process reliability and First-class product quality for printers.

The focus of the trade fair presentation will be on LED UV systems, particularly those for digital, sheetfed and web printing. Not only do they provide typical UV benefits such as higher throughput speeds and reliable printing results, but their comparatively low energy consumption and the option of format switch-off also contribute to the Sustainability of the printing process with.

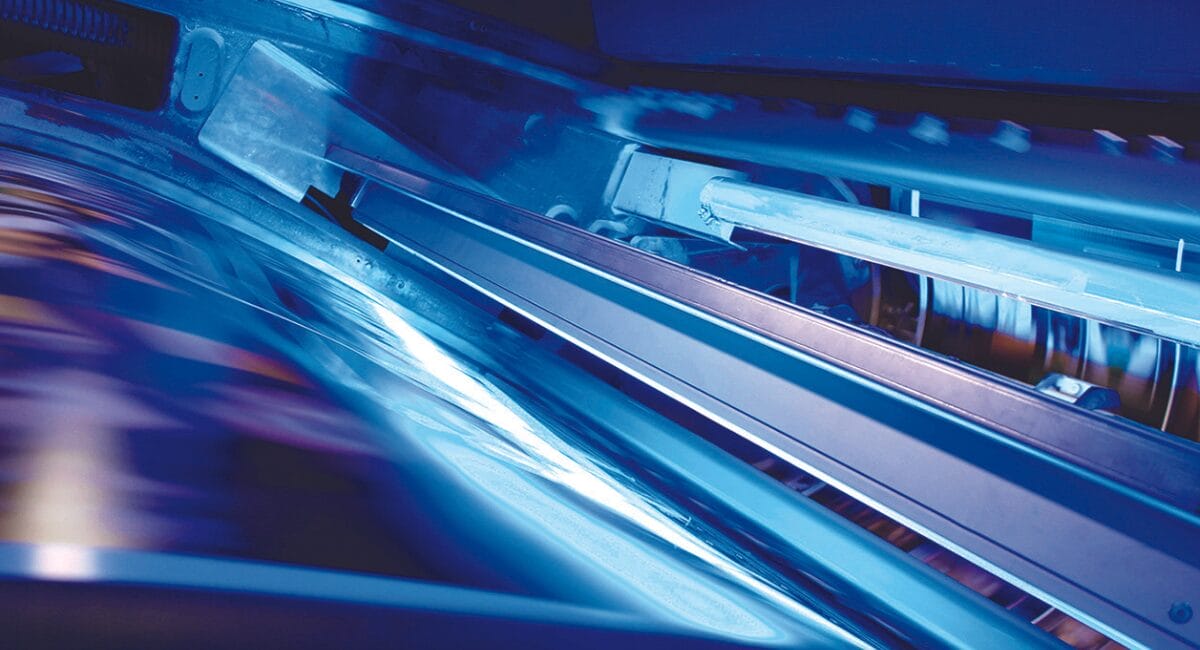

A new addition to the portfolio is the LED Powerline LC HV for the Fast and energy-efficient curing of printing inks and varnishes. The water-cooled and variable LED UV curing unit can be used for pinning and final curing in almost any printing application (sheet-fed printing in the image): whether paper or film, web or 3D.

The LED UV system LED Powerline Focus is optimised for greater distances to the substrate: A special Focussing optics ensure the best curing results even at high speeds. The modular design of the LED Powerline enables format switch-off and therefore efficient curing on substrates of different sizes. With the new UVAPrint varyCURE hybrid device, the printer has the choice of which curing technology to use for the upcoming print job.

Hönle at drupa: Hall 16, Stand D 12