Sales and application technology at MULTIPOND Wägetechnik GmbH work hand in hand with customers. Through constant market observation and close cooperation with customers worldwide, its sales professionals specialise in solving problems.

In addition, the development department advances the state of the art and develops functional solutions tailored to the given conditions. Sophisticated partial or complete solutions with maximum customer benefit. This guarantees a consistently high standard of quality and allows us to respond flexibly to even the most difficult customer requirements.

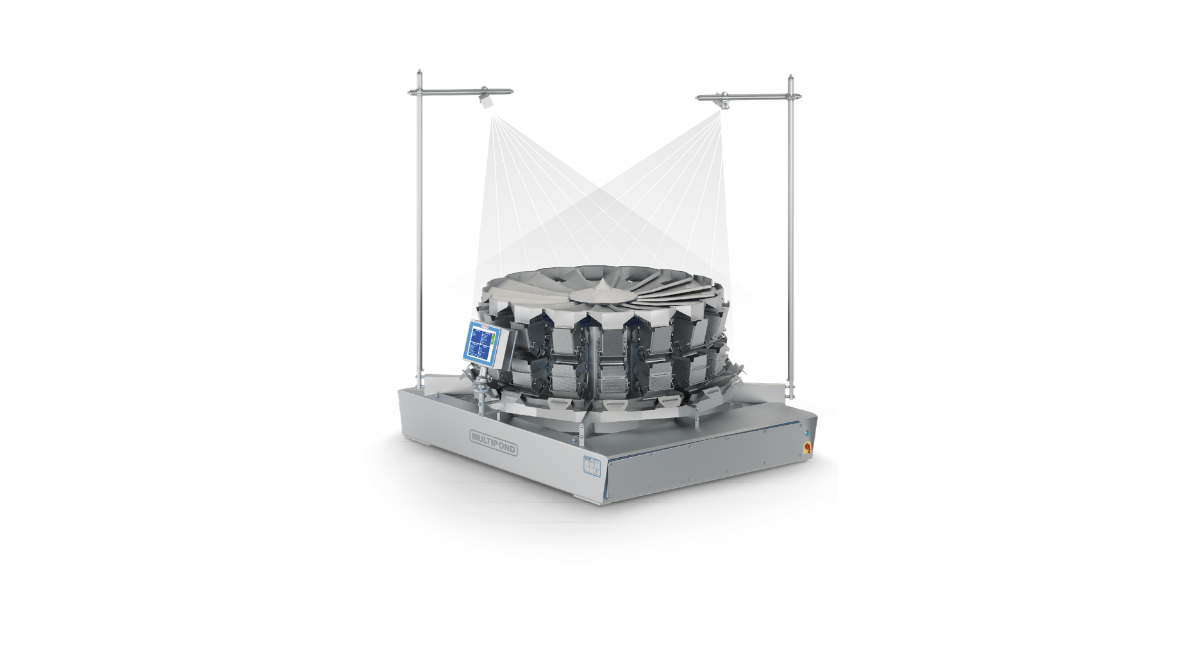

The company will be presenting two innovative solutions for special customer requirements. The solutions demonstrated include the patented ARGUS-03 camera for an optimised product flow.

The advantage of this camera-monitored scale is obvious: thanks to the automatic reaction to the image data, this system guarantees a Controlled filling of the weighing hopper. The automatic optimisation of the product flow without the intervention of the operator has a More constant dosing and the associated greater variety of combinations.

This leads to a higher speed and an even higher higher accuracy. The innovation brings measurable improvements, especially when weighing difficult products such as meat or salad.

Weighing confectionery

MULTIPOND will also be focussing on a patented solution for the Separation of breeze when weighing sugared products using a multihead weigher and sugar ring. The solution is ideal for weighing sweetened products. Rubber articles from the confectionery sector.

In this process, the sugar at the end of the dosing chutes is constructed diffusers is channelled out of the system. The sugar is transferred via the outlets to a rotating ring, the so-called Sugar ring, and drawn off via vacuum.

The multihead weigher works according to its proven system and is not affected by this. This solution is also Can be retrofitted to existing machines and thus complements the delivery programme for the corresponding products.

MULTIPOND at FachPack 2019: Hall 1, Stand 337