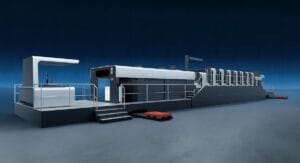

At interpack, Heidelberger Druckmaschinen AG presented a world premiere for the growth segment of high-volume folding carton printing with the completely newly developed Heidelberg Boardmaster.

The new Boardmaster is a flexographic web printing system that with a machine availability of up to 90 per cent and a maximum printing speed of 600m/min doubles productivity and thus drastically reduces the total cost of ownership in industrial packaging production. Thanks to a global increase in demand for packaged goods, packaging and label printing is experiencing structural growth and is an important core segment for Heidelberg.

"With the world premiere of our Heidelberg Boardmaster, we are providing the answer to the key customer requirements of the packaging market: cost pressure, productivity, shortage of skilled labour and sustainability."

Dr Ludwin Monz, Chairman of the Management Board at Heidelberg

The company has now presented the Boardmaster for the first time at interpack. Flexographic printing is now the most important technology in the packaging market and continues to benefit from the stable and significant growth in packaging and labelling worldwide. Today, around 15 per cent of the volume of folding cartons is already produced using the flexo process - and the trend is still rising. The flexographic printing production volume of folding cartons (flexo folding carton) within packaging printing, for example, grew at an above-average rate of 2.4 per cent.

Brand groups rely on the more sustainable folding carton

International brand groups in particular In addition to print quality, ever higher demands are being placed on sustainability and recyclability of their entire packaging range and are increasingly dispensing with plastic. According to a recent Smithers study, the proportion of fibre-based packaging, e.g. made of cardboard or paper, will have overtaken plastic packaging, which still dominates by far today, in the food sector in the medium term and will then be in the lead with over 40 percent.

The new Heidelberg Boardmaster is particularly suitable for for folding carton applications in the food and beverage sector, which are enjoying increasing popularity worldwide due to a global rise in demand for packaged products.

"With the Boardmaster, industrial packaging producers are able to significantly reduce their operating costs. With its numerous customer benefits, the machine is also an interesting alternative for many users who previously printed in sheet-fed offset large format (Very Large Format Printing/VLF)."

Christian Steinmaßl, Head of the Packaging Segment at Heidelberg

Developed from scratch, the Boardmaster is created at the Heidelberg competence centre for high-volume flexo folding carton printing at the Weiden in der Oberpfalz site.

Source: Heidelberg Printing Machines

Heidelberg - More news

Heidelberg takes over service for Schubert in Brazil

Study shows: paper packaging is becoming significantly more important

Heidelberg acquires technology and trademark rights from Polar Mohr

Networked label printing