Are material savings still possible in the production of food cans? The latest research results of a joint project show that the potential for further thickness reduction in the production of three-piece cans is far from exhausted.

Over the last decade, the decrease in the thickness of the raw material used to manufacture food cans seemed to have come to an end due to sealing problems. In most cases, the formation of creases when processing thinner and higher-strength materials set the limits of the process. But is that really the case?

In order to investigate this, a Cross-industry consortium have joined forces. The funded research project was realised with scientific support and coordination by the Fraunhofer Institute for Machine Tools and Forming Technology (IWU).

[infotext] The project consortium for the investigation of the capping technology is made up of:Material suppliers (thyssenkrupp Rasselstein GmbH, Tata Steel)

❚ Capping machine manufacturers (Cantec GmbH & Co. KG, Lanico Maschinenbau Otto Niemsch GmbH, Gebrüder Leonhardt GmbH & Co. KG Blema Kircheis, Ferrum Ltd - Canning

Technology)

Tool supplier (MAIKO Engineering GmbH, Albert Schmutzler GbR)

❚ Can manufacturers (CAN-PACK S.A., Auxilliar Conservera S.A., International Packaging Association, Glud & Marstrand A/S) and

Measuring system developer (CMC-KUHNKE GmbH, F+K Werkstoffürfung und Labor GmbH)

❚ Compound suppliers (Wakol GmbH, Henkel Adhesive Technologies)[/infotext].

Basis of the analysis for food cans

The test was carried out on a three-part food can with a diameter of 70 millimetres. For these food cans, the material strength TH550 with a thickness of 0.17 millimetres is the industrial standard for the can lids. As part of the project Five different lid materials The study also examined lid materials with a reduced thickness of 0.15 millimetres with higher strength (in the range of 600 N/mm² to 650 N/mm²) and maximum elongation (between two and approx. ten per cent).

All can lids have been identical conditions for interior and exterior coating and with the same compound system on the same system and with the same moulds at the industrial partner CAN-PACK S.A.. The can end dimensions were all within the required tolerances.

The study focussed on the Roll closureas this is the most common sealing technology. Examination of the standard industrial roll for the first sealing operation in the folding process showed the known difficulties and problems in the industrial tests: the higher the material strength and the lower the material thickness, the more the materials tend to wrinkle during sealing operation 1.

Process innovation with virtual methods

As part of the project, an FE analysis was carried out with the aim of identifying the main influences and causes for the Wrinkling behaviour to describe. It was found that a significant influence on the number and size of wrinkles lies in the relationship between the material hardness and the roller geometry.

In order to minimise creases during the process simulation, various roller profiles were analysed. Finally, a roll profile was optimised that resulted in less creasing when folding all high-strength materials. This optimised roll profile was produced by the project participants and subjected to practical testing on various sealing machines.

Industrial trials with project participants

The industrial trials were carried out by three machine manufacturers (Cantec, Ferrum, Blema) and one can manufacturer (Auxilliar Conservera) in the consortium. The sealed cans showed good dimensional accuracy with the required dimensions and were analysed with regard to wrinkling.

The most common type of test is the Stripping method and a subsequent Optical inspection by the machine operator. Here, subjective assessments can influence the tests, which is why all sealed cans were tested with a new X-ray-based, non-destructive seam measuring system from the company CMC-Kuhnke GmbH. This system provides an objective method for measuring creases within the seam. All industry partners were able to prove the improvement in the crease pattern through the optimised roller profile for all high-strength materials.

Functional test illustrates the potential

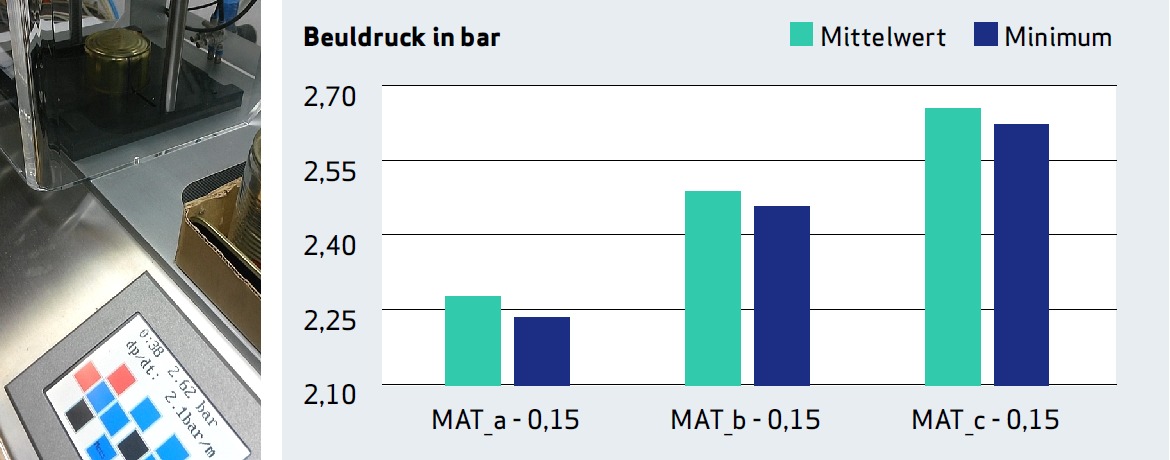

In subsequent tests, the sealed cans with all test materials were subjected to a buckling test, which showed that all higher-strength materials lead to an increase in the bearable buckling pressure.

It was also found that the materials with high strength and high elongation have a higher potential for thickness reduction.

Weight savings of up to four grams per food can possible

Within the project, the Technological proof of the reduction in the use of materials with the same functional requirements and better process stability. The industry participants estimated that with a lid material with a strength of 650 N/mm² and high elongation, it is possible to reduce the thickness of the lid sheet by 0.02 millimetres while maintaining the same function.

The effect of this reduction in lid thickness of around 20 micrometres on a standard can with a volume of 425 millilitres would lead to a weight saving of four grams per can, which, given the billions of units used in the market, would result in a Significant material reduction and corresponding cost savings could be achieved. Future series trials should confirm the results.

[infotext]The IGF project 19436 BR / 1237 "Extension of the process limits for wrinkle-free sealing of lids made of high-strength thin packaging steel" of FOSTA - Forschungsvereinigung Stahlanwendung e. V., Düsseldorf, was funded by the Federal Ministry for Economic Affairs and Energy via the German Federation of Industrial Research Associations (AiF) as part of the programme for the promotion of joint industrial research (IGF) on the basis of a resolution of the German Bundestag.The detailed The final report of the project is available from Forschungsvereinigung Stahlanwendung e. V. (FOSTA)[/infotext].