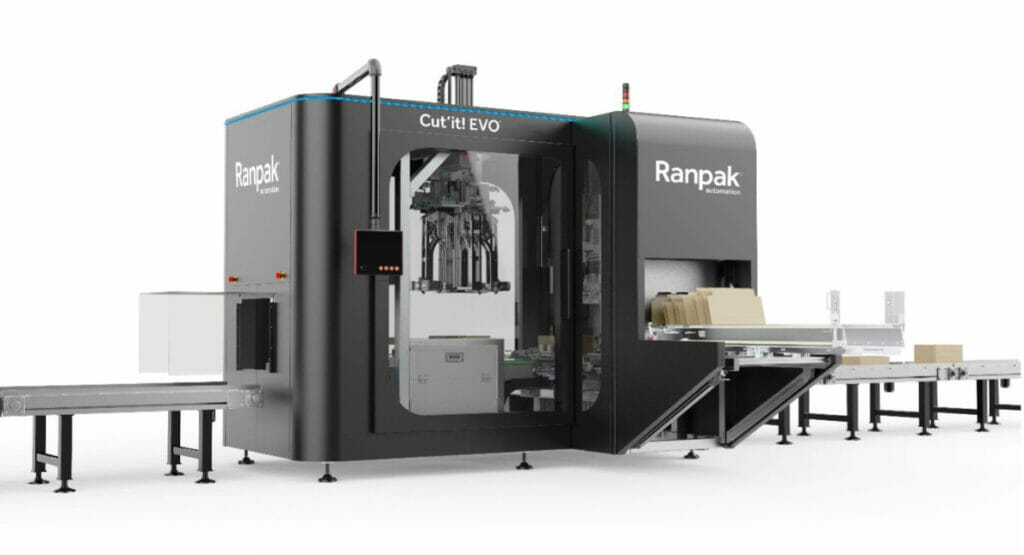

Smaller and perfectly fitting cartons mean lower shipping costs. At LogiMat, Ranpak will be presenting a new in-line packaging machine with automated cavity reduction for packaging.

The new Cut'it! EVO from Ranpak stands for an innovative packaging concept: once the products have been placed in the carton, the machine determines its highest filling point, reduces the height and automatically closes the lid so that the carton is ready for palletising and shipping. The results are Smaller boxes, faster and leaner operating processes and - thanks to the smaller dimensions of the packaging - lower shipping costs.

In addition, easy-to-open and tamper-evident packs with tear strips improve the customer's unpacking experience when removing the product. The redesigned automated system offers improved reliability and productivity as well as easier operation and maintenance. In addition, the Online access to real-time data for immediate insights into operational processes and online support enable technical support to connect directly to the system if required.

The improved system, which can process sustainable paper-based packaging solutions, will be presented at the Ranpak stand as part of a complete packaging line in an impressive virtual reality (VR) demonstration.

„The Cut'it! EVO processes up to 15 cartons per minute. This flexible solution allows companies to cope with increasing packaging requirements. This includes the ability to pack on average 25 per cent more cartons per lorry load, thereby reducing the number of vehicles required by up to 25 per cent. The Cut'it! EVO can be easily integrated into any packaging line, takes up very little floor space, offers high processing speed and reduces the need for labour/assistance. The latter plays an increasingly important role given today's difficulties in finding and retaining employees.“

Paul Spronken, Product Manager Automation at Ranpak

The new design of the Cut'it! EVO includes three processing stations: measuring, cutting/creasing and folding/lid gluing. As these three phases can be set up as independent processes, the system can also handle a higher throughput with greater reliability. In addition, the new design focusses on optimising the mechanical Shorten distances to reduce maintenance costs.

The integrated cameras make it easier to operate the machine and ensure processing quality. The camera system can store up to 40 hours of video recordings and the integrated laser-based measuring device recognises bulky, overfilled cartons in order to process them selectively and prevent system jams.

Source: Ranpak

More news about packaging machines

Krones celebrates 75 years of company history

Traffic lights prevent bottlenecks

Confectionery: Flavour alone is no longer enough

Mettler-Toledo shows inspection solutions in Düsseldorf