Lantech has new developments for an efficient packaging process in store for interpack in May. These include the new RL Automatic ring stretch wrapper and other carton packaging systems.

The highlight at the trade fair stand is the new RL Automatic ring stretch winder. The high-speed machine wraps up to 180 loads per hour with outstanding packaging quality and largely without operator intervention. out. The Metered Film Delivery function offers twice the wrapping force and therefore high stability without crushing and twisting the load or tearing the film. The Load Seeking Clamp feature protects against film tears by welding the end of the film to the load. Wrap Cycle Control allows the film tension to be adjusted during operation via the control unit. The optional Additional equipment Automatic Roll Change enables the film rolls to be changed automatically. The RL Automatic stretch wrapper is suitable for load dimensions of up to 1200 mm x 1200 mm x 2700 mm.

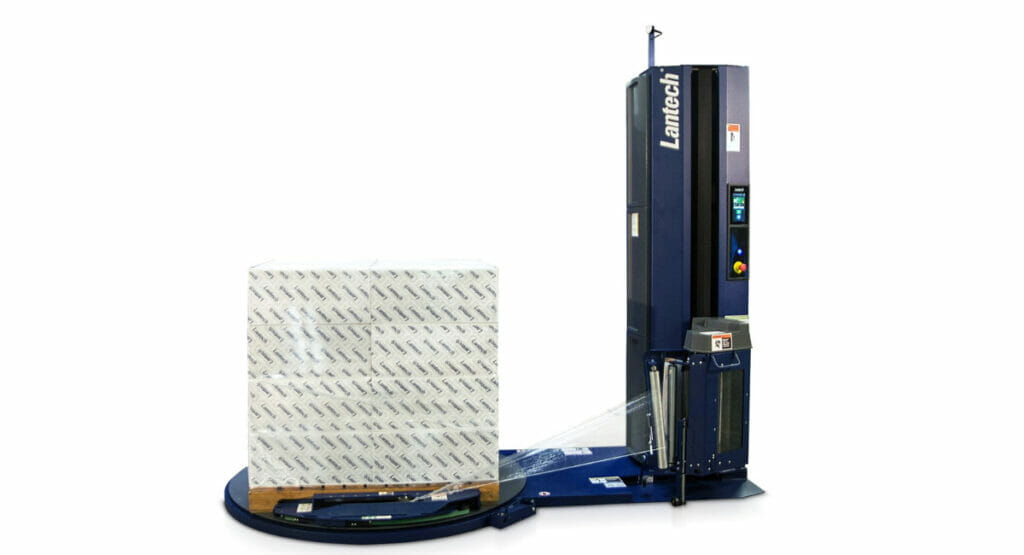

The semi-automatic QL-400XT stretch wrapper saves two minutes on each wrapping cycle thanks to the patented XT Cut & Clamp feature. The film is gripped and cut at the end of the wrapping cycle. The Process is completely mechanical and does not require its own compressed air supply or power supply. The intelligent Load Guardian control system creates special profiles with the appropriate retention force for frequently occurring loading applications. Users can process up to 35 loads per hour with the QL-400XT stretch wrapper, whereby the film can have a maximum pre-stretch of 300 per cent. Diagonal load sizes of up to 1830 mm and wrapping heights of up to 2030 mm can be wrapped.

The CI-1000 automatic inline carton erector produces up to 25 cartons per minute, which always have right angles and are therefore have maximum stability and are ideally suited for the logistics chain are. The machine also impresses with its great flexibility, as it processes many types of cartons and closures. The dimensions of the cartons can range from 200 mm x 150 mm x 150 mm to 500 mm x 325 mm x 520 mm. The carton blanks are fully controlled from the moment they are loaded into the magazine until they are output as a finished carton with a sealed base. When smaller quantities are required, the carton erector C-300 is the right choice. It can produce up to 10 rectangular cartons per minute with dimensions of up to 500 mm x 350 mm x 600 mm per minute. Other features of the machine include ergonomic loading and extremely controlled processing of the blanks.

Lantech now offers the software solution LINC (Lantech Intelligent Network Connection), which Operation, productivity, quality and costs of L-Series automatic stretch wrappers monitored. The new online tool analyses key performance indicators and draws attention to inactive machines and incorrect winding profile settings. Employees can view the data in real time via the Internet. The bottom line is Higher availability, less film consumption and improved load quality.

Source: Lantech

Lantech at interpack: Hall 13, Stand D47