Intermediate Bulk Containers (IBCs) are true space savers. Invented by the Schütz Group in 1975, these inexpensive, lightweight and practically stackable containers utilise storage space much better than steel drums, for example. The Dresden-based start-up Packwise GmbH now wants to integrate IBCs into the Internet of Things (IoT) with the Packwise Smart Cap.

Up to 20 million IBCs are travelling the world, wrote the FAZ in 2014. They have established themselves as „the“ packaging material for chemicals, food, cosmetics and pharmaceuticals. This is also due to their ease of emptying. However, the conventional system has weaknesses: Only comparatively few IBCs are washed and reused in a way that conserves resources. In most cases, the plastic inner bladder is simply replaced completely.

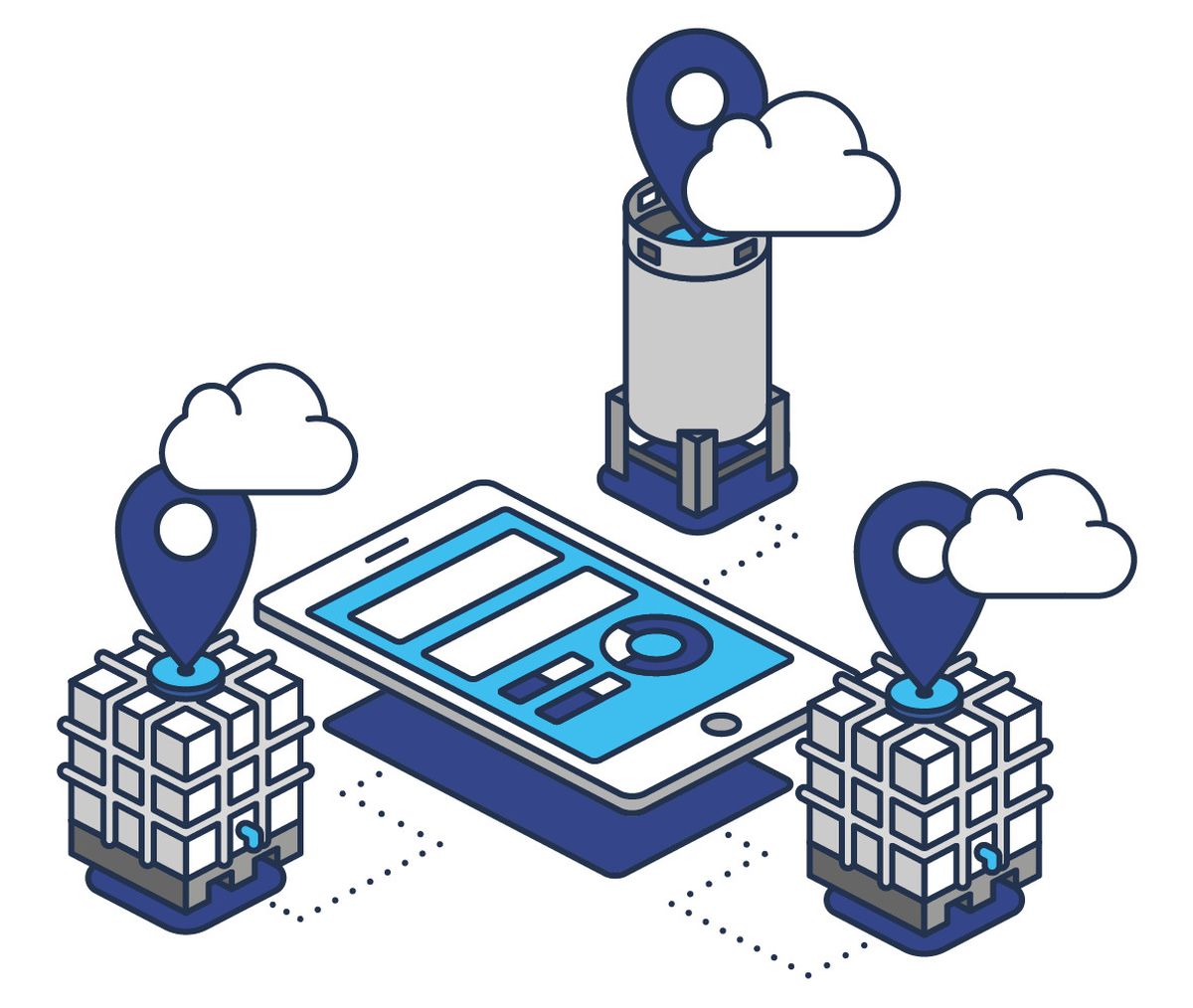

The practical containers could be utilised much more efficiently if they were integrated into intelligent, cross-manufacturer and cross-market cycles, says the Packwise GmbH. Too few IBCs are still on the move and are instead standing around unused and empty at customers„ premises. The team led by Managing Director Gesche Weger and Product Developer Felix Weger is currently preparing the market launch of the “Packwise Smart Cap", an easily retrofittable sealing lid with IoT-functionality. Companies in the pharmaceutical and chemical industries in particular should benefit from this.

Packwise was founded back in 2017 with the aim of IBC circulation system with the help of digitalisation. The first step was to develop the IT infrastructure for an online marketplace. The idea behind it: Instead of using individual, manufacturer-dependent circulation systems, customers should be able to return the bulk packaging materials emptied at the respective daily price. Packwise would use a network of service providers to organise the collection Reconditioning and coordinate the delivery. Even then, a smart lid with IoT capabilities was designed to provide automated information on the location and fill level of an IBC in real time.

Lively interest from the pharmaceutical and food industries

The more companies used the Packwise service, the clearer it became Felix Weger the importance of the Smart Cap: „We are offering customers from the pharmaceutical, cosmetics and chemical industries in particular a service that did not yet exist in this universal form.“ Gesche Weger adds: „With the Smart Caps our customers optimise their IBC logistics. Previously, companies that had received filled containers had to instruct the supplier separately to collect an empty IBC. This notification is now automated.“ The entire process is accelerated. As soon as a container has been emptied, the filler receives an automatic message and can coordinate their scheduling accordingly.

The smart cap features are at least as important as the options for increasing efficiency for the Product backorder and quality assurance. Over the entire Supply chain In addition, the Smart Cap provides information on the container's location, fill level and temperature - via „plug & play“. This is because it can simply be attached to existing IBCs without any further effort.

With the lid with added value, bottlers could also realise new business models, explain the developers. Because continuous information on the fill level can be called up, the Pay-per-use offers This is just as possible as contracts in which, for example, chemical manufacturers assure their customers that a certain quantity of certain substances will always be available.

Mobile data transmission in real time

The intelligence is channelled into the smart caps via a sophisticated sensor system and numerous mobile communication interfaces. All devices are equipped with a GSM module and a mobile SIM card. This means they can dial into wireless telecommunications networks virtually anywhere in the world. They are also GPS, Bluetooth and WLAN interfaces on board. „The device software is programmed in such a way that it always selects the most favourable option for mobile information exchange,“ explains Felix Weger.

Besides Position, level and ambient temperature sensors the communicative closures also have acceleration sensors. This means that it is possible to determine in real time whether a container of a Shock load and may have been damaged as a result. Similarly, temperature information could be used to draw conclusions as to whether a particular substance was always stored in the environmental conditions defined for safe use.

Position and fill level data in turn facilitate logistics planning and also allow a container to be tracked seamlessly throughout the supply chain. Even within the company, continuous information about the container location increases production efficiency, explains Felix Weger. At any time Micro-location tracking determine whether a container is still in the washing plant or being repaired, or whether it is already at a delivery point and can be refilled.

Data security is a top priority

Packwise attaches great importance to data security. All information is transmitted in encrypted form. It is also fundamentally independent of the contents of a container. Only by linking the unique ID of the smart cap with information from a ERP system in the bottling plant, conclusions could be drawn about the contents.

How do users benefit from the sensor technology? Felix Weger gives an example: if a bottling plant delivers an IBC with a perishable liquid and the software detects that the container has already been opened but not yet emptied after a certain time, a warning can be issued by comparing it with the best-before date. The same data can also be used to First opening information are generated. In many cases, the warranty of bottling plants ends with the first opening of a container.

Packwise is particularly proud of the reliability of its battery-powered smart caps. A service life of at least five years is guaranteed. In addition, as Felix Weger emphasises, operation is almost fault-free: „Within three years, not even one per thousand of the Smart Caps fail.“ Of course, the products ready for series production also have UN approval for Hazardous goods packaging have, for Food contact certified and authorised for use in potentially explosive atmospheres.

[infotext icon]Success on the capital market

Packwise's idea for intelligent IBC caps has attracted a great deal of interest on the capital market. Last year, the Dresden-based start-up successfully completed a first round of financing to drive forward the development of the smart cap.

A second round of financing has now been realised for the transition to series production. A lead investor was found in the form of Technologiegründerfonds Sachsen (TGFS). The „family offices“ Golzern Holding and „Hüttenes hoch drei“ are also participating. According to Packwise, a total of one million euros is available for the further expansion of the company's activities.

Before the market launch is planned for early 2020, extensive practical tests will be carried out. Pharmaceutical and chemical manufacturers in particular are participating in these tests, says Packwise with.

[/infotext]