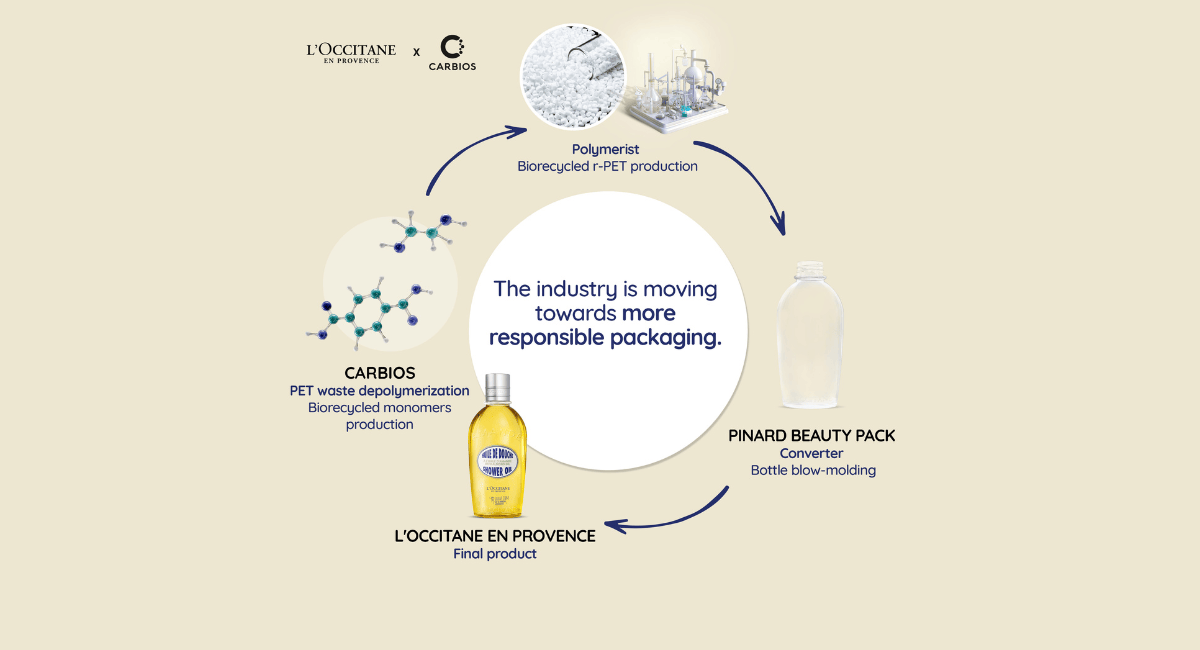

Carbios and L'Occitane have developed a transparent PET bottle made entirely from material from enzymatic recycling. Local collection and production processes are integrated into the recycling process, which further shortens transport routes and has a positive impact on the product's emissions.

In collaboration with converter Pinard Beauty Pack, this bottle is an example of the shared desire to build an efficient European recycling sector to accelerate the transition to a circular economy for plastics and fulfil brands' commitments for more sustainable packaging solutions. The bottles to 100 per cent recycled PET bottle from the enzymatic depolymerisation process from Carbios was produced by a European value chain that is committed to the responsible use of sustainable materials.

„Carbios' innovation accelerates the transition to a circular economy by providing an alternative to petroleum-based PET and a circular solution for PET recycling that minimises CO2-emissions by 57 per cent. However, in order to create an efficient recycling sector, all players in the value chain must work together. The long-term partnership between Carbios and L'Occitane demonstrates this shared desire to promote more responsible consumption. The bottle produced with L'Occitance and its processor Pinard shows how the industry is evolving.“

Emmanuel Ladent, CEO Carbios

Production of the bottle began with the local delivery of PET waste (already collected, sorted and processed) to the Carbios industrial demonstrator in Clermont-Ferrand, France. The waste consisted of coloured bottles, multi-layer trays and residues from mechanical recycling that are not currently recycled using conventional technologies. Carbios decomposed the PET waste into its original monomers, PTA1 and MEG2 , with the help of its biorecycling technology. The monomers obtained in this way were then processed within Europe into new, fully recycled PET resins repolymerised. In Oyonnax, France, these resins were blow-moulded by Pinard Beauty Pack into bottles according to L'Occitane's specifications and then bottled with the shower oil at the Manosque plant.

„At L'Occitane en Provence, we are „Cultivators of Change“ and we are proud to be part of this forward-thinking industry. Today, just over 50 per cent of our PET material is of recycled origin. Thanks mainly to Carbio's and the depolymerisation technologies, we will be able to reach 100% for all our retail bottles by 2027. We are very pleased with the quality of the bottle produced in collaboration with Carbios and Pinard, which will allow us to reduce our dependence on fossil-based plastics and offer a viable alternative with equivalent quality and transparency, which is important to showcase our products. “

David Bayard, RGD Pacfiaging Director L'Occitane

This European approach optimises the environmental benefits of the technology and the life cycle analysis (LCA) of each product by taking the Transport routes shortened and local collection and production processes integrated. In order to meet the needs of international brands, similar chains must be set up around the world and modelled on this example.

„At Pinard, we are delighted to have reached this new milestone and to be involved in the production of the first L'Occitane en Provence bottle made with Carbios“ revolutionary technology. This bottle was blown under the same conditions and with the same parameters as virgin PET or mechanically recycled PET, a great advantage for the use of Carbios technology. We see a strong demand for high-quality recycled PET that can be used to produce the same applications as virgin PET."

Paolo Coelho, Plant Manager of Pinard Beauty Pacfi

The latest life cycle analyses show a 57 per cent reduction in CO2-emissions compared to the production of new plastic, and for every tonne of recycled PET, 1.3 tonnes of crude oil are avoided. Compared to conventional recycling, enzymatic recycling is 5 times more circular (calculated according to the Ellen MacArthur Foundation's Material Circularity Indicator). Thanks to its highly selective enzyme, which is optimised for efficient PET degradation, the Carbios depolymerisation technology processes all types of PET waste, including coloured, multi-layered or textile waste that cannot be recycled using current technologies. Carbios' technology thus complements mechanical recycling processes. In addition, the two monomers produced (PTA and MEG) enable the manufacture of recycled PET products that are suitable for food contact and have the same quality as products made from petroleum.

Source: Carbios