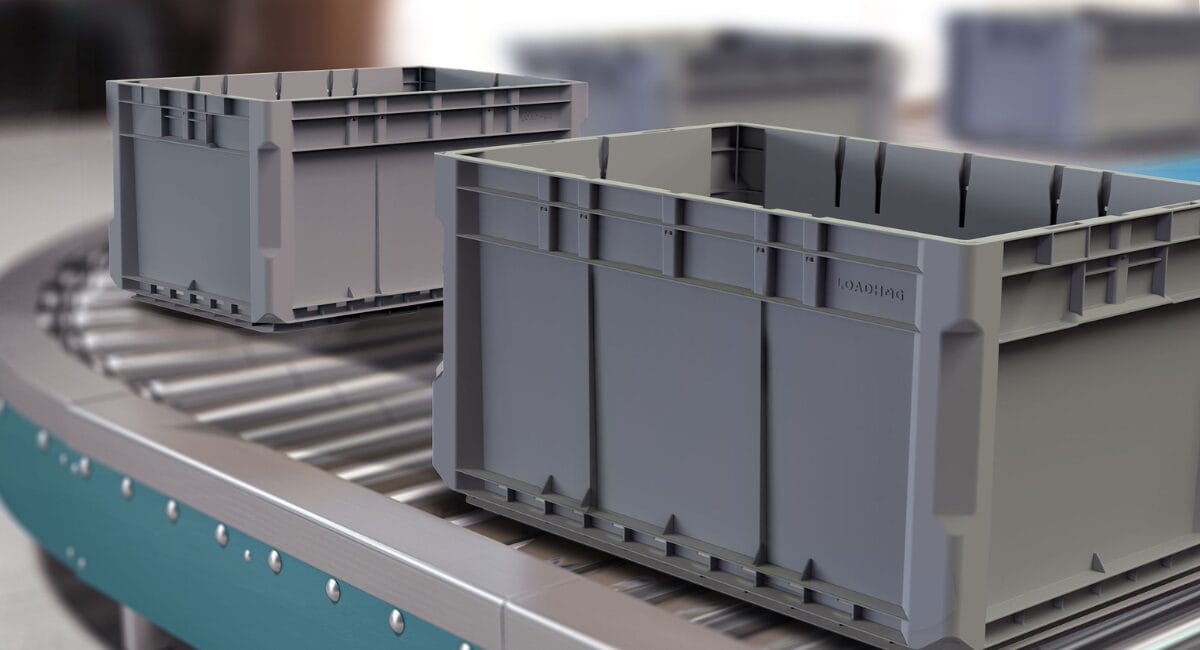

Packaging manufacturer Loadhog launches a new container for intralogistics. The Autotote 64 has been specially developed to meet the challenges of intralogistics automation.

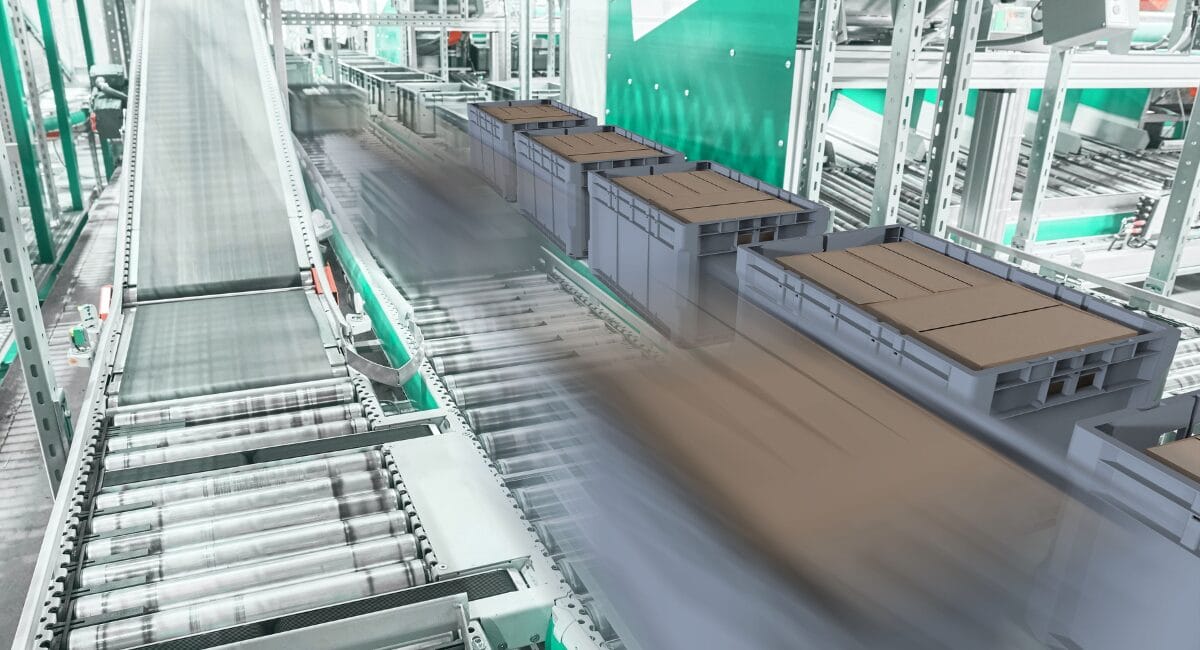

The patented Autotote 64 has been developed to run smoothly and quietly in automated systems, while offering a high degree of strength and durability.

„We started developing products for automated systems back in 2021 and launched our Autotote 6545 in 2022. Having supplied over 350,000 of our Autototes to customers in a range of industries across Europe, we have now channelled all our expertise and experience into developing a new standard container specifically designed for use with AMRs, conveyors, shuttle storage systems and other ASRS technologies.“

Martin Baker, Senior Design Engineer at Loadhog

The Autotote 64 has a one-piece, double-walled base that makes it completely smooth inside and out. This construction, which is achieved by casting instead of welding, makes the container both lighter and more cost-effective to manufacture. The bevelled, cantilevered bottom edge of the product reduces deflection and provides a certain degree of flexibility in order to achieve a smoother and quieter transition between the conveyor belts when changing direction and over rollers. The diagonal ribbing strengthens the floor and the fully enclosed underside protects conveyors, helping to save on belt maintenance costs while improving grip and speed. The Autotote 64 also features multiple reinforced interaction points to optimise movement within an automated shuttle system.

The Autotote 64 has a footprint of 600 x 400 mm and is available in two heights: 270 mm and 320 mm. It is suitable for loads up to 50 kg and temperatures from -20 to +40 °C suitable. In addition to the benefits offered by its base, the container has hollow corners that provide high impact resistance while allowing smooth transport around corners. The new bin also features offset drainage holes designed in accordance with FM Global data sheet 8-34. In line with Loadhog's ambition to achieve a net zero footprint by 2030, the Autotote 64 made from recycled material, to avoid the UK plastic tax. Customers can opt for production from 100 per cent recycled material and still get excellent sound performance and floor rigidity.

„Sustainability is further enhanced by the wall thickness of 2.3 mm. This means that less material is needed for production, resulting in a lower product weight without compromising on strength and durability. In this way, the Autotote 64 proves to be a valuable addition to the circular economy.“

Martin Baker

The Autotote 64 is either equipped with Closed handles or with open handles available with a large inner radius for ergonomic handling. Labelling options include in-mould labels in 10 different locations. Dividers can be used to maximise the number of items within each container, with a choice of wide, long or half-width dividers for optimum versatility in up to 8 sections. The dividers feature a flexible edge that can be easily removed and, unlike competitor versions, do not have interlocking slots that can be prone to weak points. The Autotote 64 can be provided with an imprint or embossing while the bag itself is available in a range of colours other than the standard grey.

Construction will soon begin on Loadhog's brand new production facility in Obernai, 10 miles south-west of Strasbourg. The new factory, due to open in 2025, will ensure shorter delivery times for Loadhog's European customers while reducing the company's environmental footprint. Due to the high demand for automated intralogistics solutions on the continent, the first product to leave the new production line will be the Autotote 64.

Source: Loadhog