At Fakuma, the Pöppelmann Group's trade fair presence is all about the use of post-consumer recyclates in various applications. The solutions are offered in series and help companies to reduce their greenhouse gas emissions.

The more resource-efficient and climate-friendly design of plastic products is at the centre of the trade fair appearance of the Pöppelmann Group on the Fakuma 2023. The trade fair highlights from the various business areas of the plastics specialist from Lohne focus on the utilisation of recyclates and show how eco-design and sustainable material selection can be used to greenhouse gas (GHG) emissions in series production.

Pöppelmann supports companies that want to make their products more sustainable by calculating GHG emissions for specific products. From this, the company derives possibilities for optimisation, e.g. the Use of climate-friendly recyclates, modified production technologies and design adaptations that, at best, create closed material cycles. to achieve. Innovative series products from the business units illustrate the savings that can be achieved in this way. Pöppelmann also shows ways to reduce the carbon footprint of products for industries in which the use of post-consumer recyclates (PCR) is not possible for regulatory reasons.

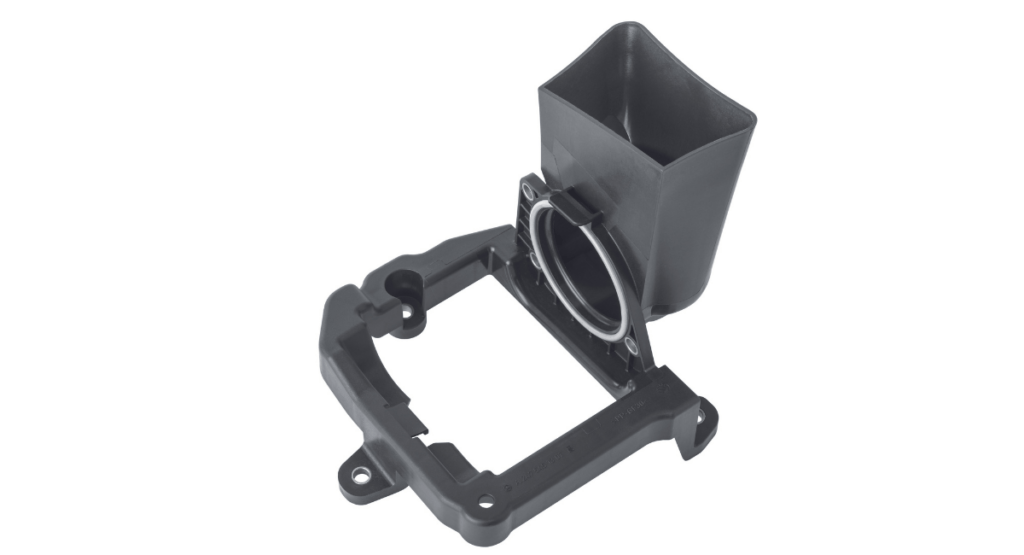

Together with a well-known vehicle manufacturer, the Pöppelmann K-TECH division is demonstrating how recyclates can be used to realise sophisticated technical components made of plasticThe so-called holder sound generator is now available not only from virgin material, but also in a version made from a PCR PP-GF30 suitable for series production, the components of which come from used plastic packaging from household recycling collections. For a third variant, PCR PP-GF30 is used together with 10 per cent of other household waste materials that have been processed in a special procedure.

Their use eliminates the need for landfill. This avoids the greenhouse gases produced during decomposition. The production of the holder sound generator of the second variant saves around 44 per cent CO2e one, variant three, including the residual materials, even 50 per cent. The item has been mass-produced from PCR since 2020, making it one of the first series-produced components in the automotive segment whose plastic content comes entirely from this source. This was well received in the industry: the product variant made from PCR PP-GF30 was honoured with the „Sustainability Award“ 2022 from the industry association SPE Central Europe (International Society for Plastics Engineering).

The Pöppelmann KAPSTO division, which specialises in protective caps and plugs for industrial applications, is represented at Fakuma with new standard series for e-mobility components - and is also focusing on greater sustainability in series production. The standardised series includes caps and plugs for the high- and low-voltage range as well as special protection solutions for VDA PS3 quick connector systems. The Articles are made from 100 per cent post-consumer recyclate as standard in the plastic used. offered.

In terms of specific products, analyses have shown that products made from 100 per cent PCR can reduce CO2e can be saved. Overall, Pöppelmann KAPSTO has expanded its programme of protective solutions made from PCR or from a high proportion of PCR plus virgin material, thus offering a wide range of products. Range of protective caps and plugs in many different colours as standard as a resource-saving variant to.

Pöppelmann FAMAC specialises in technical functional parts and assemblies as well as plastic packaging for the food, pharmaceutical and cosmetics industries as well as for medical technology. Plastic components for breathing system filtersThanks to the design optimisation, which resulted in a square design, the filter material is now used even better, as there is less waste. At the same time, the resource-saving article concept according to Eco-design criteria for material savings in the manufacture of the product and reduces greenhouse gas emissions in logistics thanks to the space-saving design of the components and good stackability. The new design has reduced GHG emissions in the area of logistics and transport by 3.3 tonnes of CO2e or 32 per cent. Pöppelmann FAMAC thus proves that even in the strictly regulated field of medical technology, more sustainability can be achieved in various ways.

Source: Pöppelmann

Pöppelmann at the Fakuma: Stand B5-5107

More news on plastics and composites

Women in Packaging: Committed entrepreneur with team spirit

Smart packaging from conception to recycling

KHS relies on Plasmax barrier technology

Reusable containers for continuous material flows