While plastics producers are currently having to adjust to the effects of the war of aggression in Ukraine, they have seen increased demand at home and abroad in 2021. Plastics Europe presented the latest figures and addressed the challenges facing the industry.

The year 2021, according to the outgoing Chairman of the Executive Board of Plastics Europe Germany, Dr Michael Zobel, is of economic ups and downs This was characterised by the economic downturn, meaning that stability never really materialised. According to Dr Zobel, dampers due to renewed lockdowns, material shortages on the markets and strained supply chains were just as much reasons for this as significantly higher prices for primary products and energy.

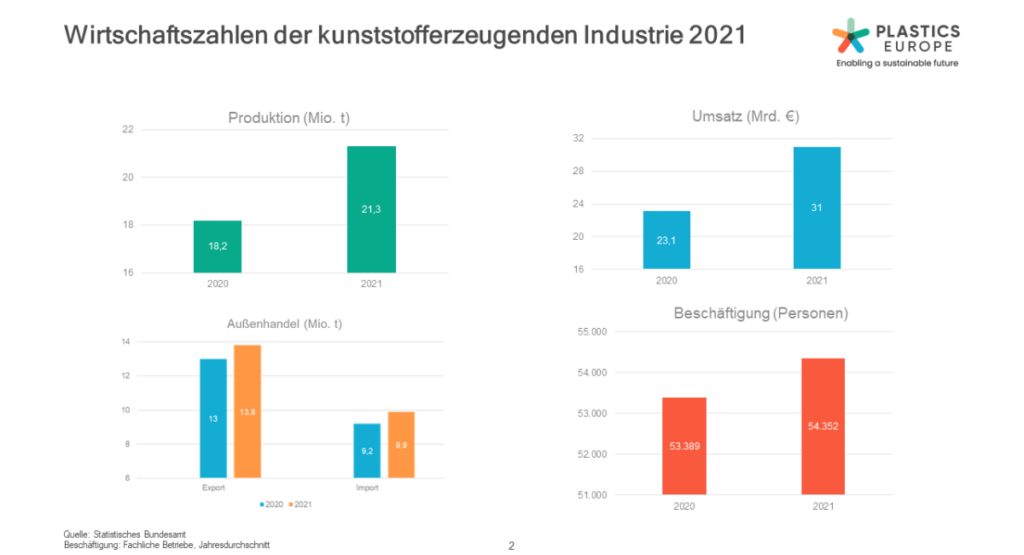

Industry performs well

It was precisely in this context that the industry had a successful financial year, according to Dr Zobel. The Plastics production in Germany in 2021 up 17.2 per cent on the previous year to 21.3 million tonnes. The total turnover (domestic and foreign) of plastics producers rose by 33.8 per cent to 31 billion euros and resulted in equal parts from volume growth and higher prices.

According to Dr Zobel, the resilience of the industry was due to both the possibility, to be able to pass on some of the price increases due to high demand, This is also due to the flexibility of the companies - for example by switching their customers to plastics, which had a higher level of supply security, or with external purchases of primary products that are usually produced internally.

Effects of the war

Dr Zobel made it clear that the Economic volatility of the pandemic period cannot be compared with the challenges and effects of the war in Ukraine in 2022 is. For example, the Russian war of aggression in Eastern Europe jeopardises the security of raw materials, significantly increases the cost of energy and disrupts or even completely interrupts transport routes. Overall, significantly higher production costs combined with a gloomy global economy are threatening to cause a Slump in purchasing power and demand. According to Dr Zobel, the extent to which plastics producers will be able to pass on price increases in this environment as they did in 2021 is questionable.

„Natural gas accounts for a good 44 per cent of the total energy consumption of plastics producers, primarily as an energy source for large-scale plants. A gas embargo would bring parts of production to a standstill, as our companies would have to switch off these large-scale plants - and they cannot simply be switched off and on again. Our position is therefore a clear “no" to a gas embargo.

Dr Michael Zobel, Chairman of the Board Plastics Europe

Policy support

Ingemar Bühler, Managing Director of Plastics Europe Deutschland, then spoke about the upcoming, decisive Setting the course for the plastics industry. A political reprioritisation is required that takes a holistic view of the current situation: „We must Invest in securing our acute ability to act, but also implement the green transformation of our industry with the utmost urgency“. The immediate priority is to ensure that the required energy is available and affordable. Politicians need to make pragmatic changes here and are already doing so to a large extent.

At the same time, according to Bühler, more should be done to achieve the 1.5-degree target set in Paris and avoid irreversible effects on the climate - with more circular economy, renewable raw materials and renewable energies. According to Bühler, plastics manufacturers need strong partners in the value chain for all of these tasks, who have already come together in the „We are plastics“ alliance to master future challenges together.

Source: Plastics Europe

More news on plastics and composites

Returnable solution for e-commerce returns

interpack 2026 puts packaging materials in the spotlight

Refresco uses laser technology for lighter PET bottles

Starbucks strengthens cup recycling