The expertise of Smart-Flow Europe SA and Gamma-Wopla SA, headquartered in Mouscron (Belgium), relates to the development and production of standard and customised solutions. The company responds flexibly to the needs of its customers and recently presented its new reusable pallet box.

The company sees itself as a partner for international logistics and focusses on flexibility, reliability and customer proximity. The customer base spans the automotive, electronics, retail, pharmaceutical and cosmetics, food, chemical, agricultural and poultry industries. The product portfolio is broadly diversified, is constantly being expanded and is available in various dimensions and material qualities. modular built. The programme includes a complete range of plastic pallets, collapsible plastic reusable large load carriers, nestable and stackable plastic containers, fixed and foldable handling containers and universal transport rollers.

Partner for smart packaging

This is Sustainability an important guiding principle. The containers can be particularly Frequently reused At the end of their useful life, the boxes are bought back from the manufacturer in an economically attractive way and used 100 per cent as raw material for pallets. recycled become a reality. Customised solutions are developed quickly and flexibly, from prototyping by the R&D department to the implementation and production of new plastic pallets, boxes or large load carriers.

pj: Mr Vandewiele, your company is innovative and strongly customer-orientated. As one of the CEO's two sons, you are responsible for Smart-Flow's products. At FachPack, in addition to solid, stackable plastic containers from Gamma Wopla in Euro format, which impress with their different and harmonised dimensions thanks to their modularity and precision fit, you also presented the Large load carrier Smart-Sleevepack SF800SP from Smart-Flow in the bag. How was the response?

Gregory Vandewiele: The reaction of all visitors to whom we presented the new Smart Sleevepack was a very positive surprise. I am pleased to say that some very important companies from the automotive, distribution and retail sectors have shown great interest in such a packaging solution, so that after the trade fair we received many requests for quotations or further technical information and in some cases also for specimens for test use. In particular, there was a good response to the Pallet with skids and the Closing and fixing system for the complete packaging unit into a compact and stable box.

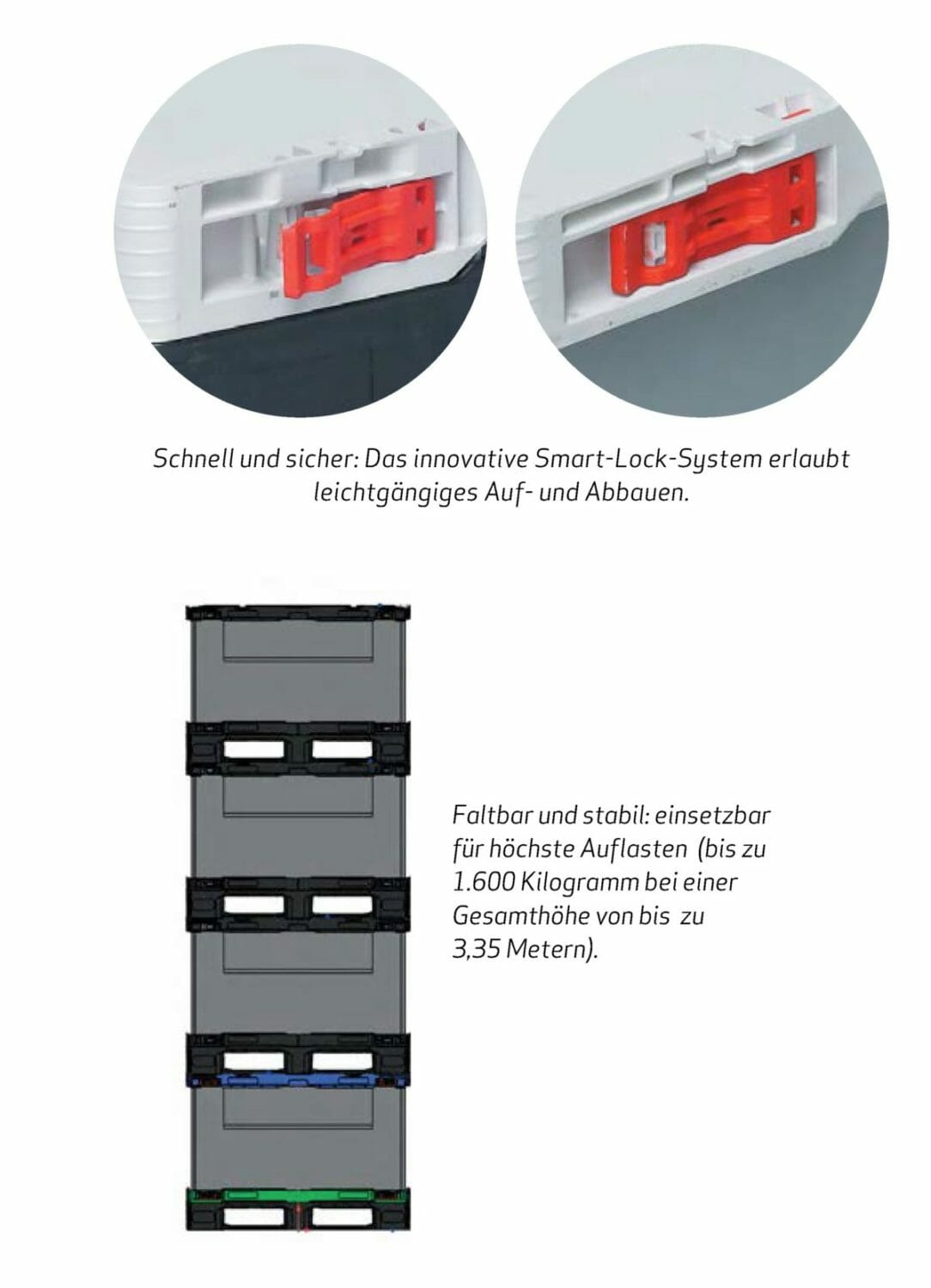

pj: Has the Smart Lock system been specially developed for this container? And how does it work?

Gregory Vandewiele: We developed the Smart Lock system ourselves in-house developed. Our young and innovative team of designers spent more than six months analysing and comparing different solutions. They not only looked at plastic packaging, but were also inspired by solutions in the Fashion world be inspired. Like all good systems, our Smart Lock system is simple but strong and durable.

pj: The container is very stable and allows a load of 1,600 kilograms. How did you achieve this?

Gregory Vandewiele: The stability of a folding box depends on three factors A strong base (the pallet), a stable box and a compact cover on top, in our case weighing eight kilograms. We measured the load of 1,600 kilograms in our internal test series. It is planned to have the Smart Sleevepack tested by the Fraunhofer Institute.

pj: For which users was this package primarily developed?

Gregory Vandewiele: Our aim is to reach a wider range of industries, but with a special focus on the Automotive industry and the Logistics.

Clever Reusable packaging

The Smart sleeve pack SF800SP has special properties. The foldable, robust reusable pallet box consists of a pallet with runners, the pallet base (tray), a foldable pallet box and a lid. The complete construction is equipped with an innovative Smart-Lock system and can be assembled and disassembled in a few simple steps. It was developed as an alternative to rigid, heavy lattice boxes, disposable transport packaging made of corrugated cardboard, plastic film or straps. In short: smart reusable packaging.

For indoor and outdoor use

Thanks to the robust material of the new containers, the highest loads can be packed and transported safely, neatly and securely. The non-slip lid with integrated handles also protects the goods from contamination and loss. The Smart-Lock system enables quick and secure self-locking and gives the load carrier a secure hold. Extra stability. When folded and empty, the box is very small, as it can be quickly and precisely stowed away neatly and safely between the base and the lid.

The simple assembly and disassembly of the folding box and pallet means that Ergonomics and Occupational safety significantly improved. The stackability of the large load carrier has also been optimised. A total of 1 + 3 boxes can be stacked with a stacking weight (superimposed load) of up to 1,600 kilograms stack stably on top of each other. The attractive empties return rate of up to 75 per cent and the relatively low tare weight reduce freight costs and increase storage capacity.

[infotext icon]The sister companies Smart-Flow Europe SA and Gamma-Wopla SA have been part of the family-run group for 27 years VANDEWIELE and specialise in the development, production and distribution of reusable plastic pallets and containers. The products are nestable, stackable and foldable and can be attractively recycled. Compatible and modularly combined as complete packaging solutions, they fulfil the highest logistics requirements.