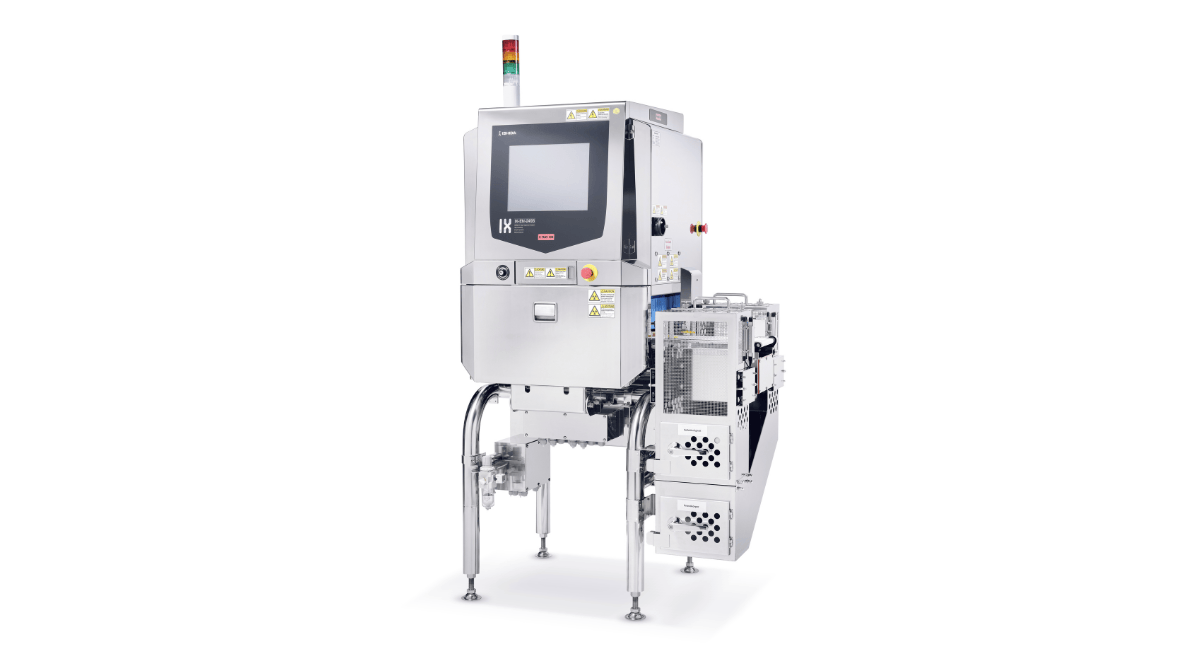

Ishida offers a new X-ray inspection system for very lightweight tubular bag packaging. The system enables foreign body detection at high speed and can be integrated into existing lines with a compact design.

Manufacturers of lightweight tubular bag packaging containing confectionery and baked goods, for example, were able to Foreign body checks often only carried out on secondary packaging until now to be carried out. In the event of a complaint, the entire multipack or outer carton had to be rejected, which resulted in costs and waste. Now Ishida The newly developed IX-EN-2493-Compact X-ray inspection system provides a solution for the Efficient control of lightweight primary packaging. The device keeps pace with the high output of flow-wrapping machines and achieves belt speeds of up to 120 metres per minute - twice as fast as a standard X-ray inspection system.

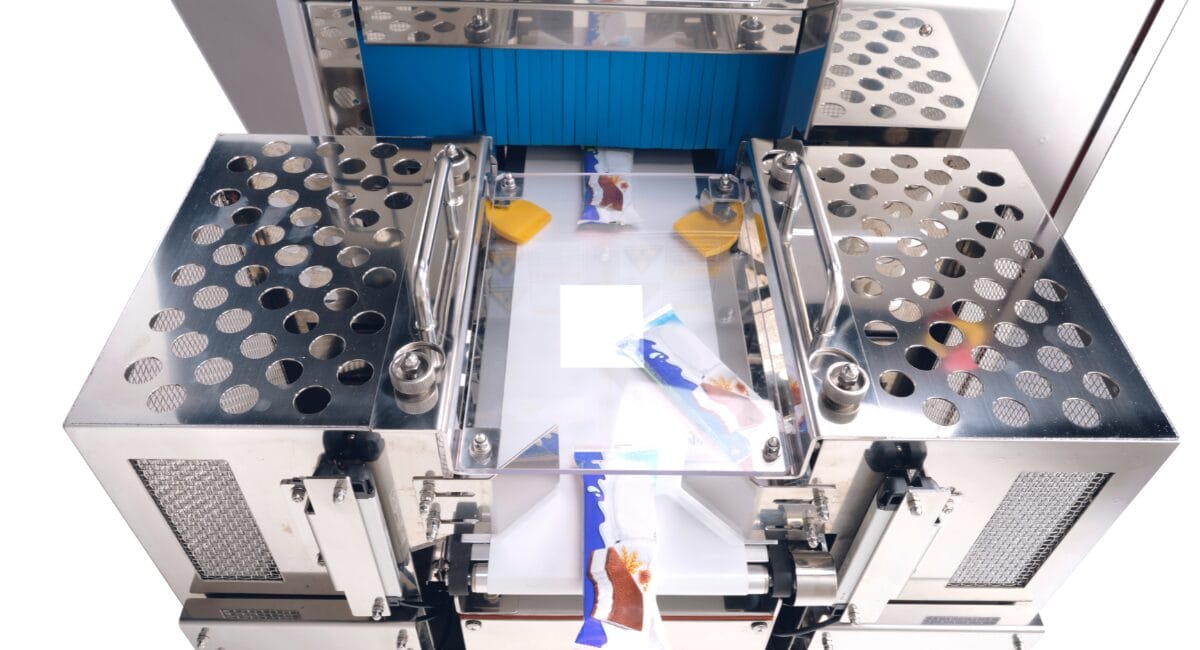

The key to achieving the high speeds is the special interrupted conveyor belt design of the IX-EN-2493-Compact. With conventional x-ray inspection systems, lightweight packaging can be displaced on the conveyor belt due to contact with the protective curtains at the inlet and outlet of the inspection chamber, resulting in product jams. The new Ishida system, on the other hand, X-rays the packaging as it passes through the gap in the conveyor belt and the X-ray beam is then shielded by two metal plates. This Design feature enables the use of shortened safety curtains, which do not affect the position of the packaging on the conveyor belt.

The IX-EN-2493-Compact X-ray inspection system features Ishida's proven Genetic Algorithm (GA) technology. This allows the operator to use the device for Highest sensitivity to certain foreign bodies optimise. The system not only reliably detects foreign objects made of steel, aluminium, tin, glass, stone, hard rubber and Teflon, but also other quality problems such as damaged or misshapen products.

Another special design feature of the Ishida IX-EN-2493-Compact X-ray inspection system are two separate ejection containers for products with foreign objects and for products with other quality defects. The containers are both accessible from one side of the conveyor belt to increase operator convenience. This also minimises the minimises the footprint of the appliance and facilitates integration into the packaging line.

Source: Ishida