Plant-based meat alternatives are becoming increasingly popular. Companies are partially reorganising their production and need to ensure high product quality. Minebea Intec offers suitable weighing and inspection solutions.

Hygiene and product quality are important in the production of plant-based meat alternatives. In order to get as close as possible to the traditional schnitzel, steak or burger in terms of shape, consistency, flavour, smell and mouthfeel, it is necessary to highest quality standards in production. To bring the ingredients together in the right proportions, companies work with automated mixing systems that are equipped with high-precision load cells from Minebea Intec are equipped.

„Our weighing solutions guarantee precise, continuous, fast and flexible dosing processes and minimise material losses. Our Novego weigh module was specially developed for tank and process vessel weighing in the food and pharmaceutical industries. The hygienic complete solution offers a variety of innovative features for simple, error-free installation and maximum resistance to lateral forces.“

Yannick Salzmann, Global Product Manager at Minebea Intec

„With the help of dynamic checkweighers, companies can optimise their production processes, improve material and resource management and increase the accuracy and consistency of production processes. Our Flexus checkweigher is the ideal solution for maximum product quality - regardless of whether customers want to check product weight or completeness or optimise their filling and sorting processes.“

Lars-Henrik Bierwirth, Product Manager at Minebea Intec

The high-resolution EMFR load cell technology ensures precise weighing results and High throughput of up to 600 pieces per minute. The Flexus checkweigher can be integrated into existing production environments. Changing line configurations and quick product changes are handled quickly and easily. Optional stainless steel tables allow the Flexus checkweigher to be cleaned easily and safely.

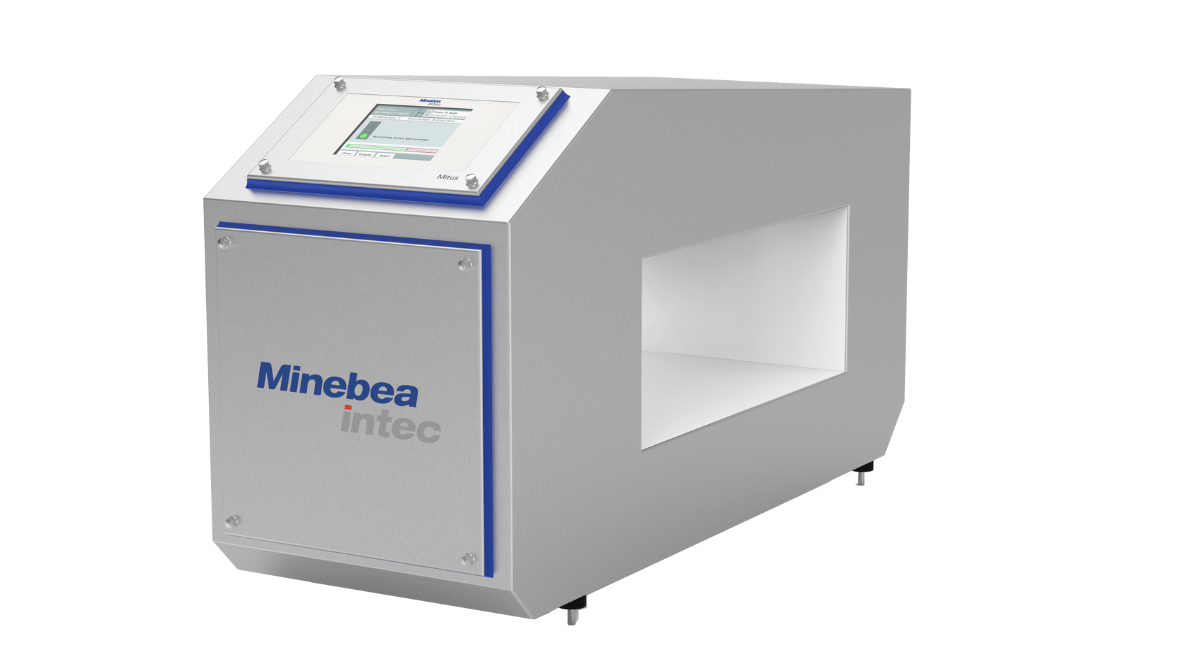

In addition to checkweighing, the Foreign body control in the meat substitute industry an important role. The new Mitus metal detector with innovative MiWave technology enables precise detection of metallic foreign objects, even with the largest product effects. With MiWave, a large number of frequencies are modulated onto the transmitted signal, which are then separated and analysed by a analysed separately by an intelligent algorithm. With the help of this division, the products can be symbolically inspected from several perspectives. This information content enables high search sensitivities to be achieved despite large product effects.

The Mitus metal detector is available in standard sizes as a rectangular, round or compact detection coil as well as a free-fall and pipeline application, so that it can also be used with limited space and, depending on requirements, integrated into production systems can be used. The Mitus metal detector can also be easily combined with additional weighing technology if required.

To identify tiny foreign bodies and remove the contaminated products, Minebea Intec offers a portfolio of X-ray systems for the inspection of packaged products. Typical applications include cartons, boxes, bags, pouches, trays and portion packs, which can contain a wide variety of dry or liquid food products. The Dylight and Dymond models have been specially developed for these applications. They are characterised by a Hygienic design in accordance with the EHEDG principles and high detection sensitivities with low power consumption.

The company has launched the Dypipe X-ray inspection system for viscous and liquid products such as vegan mince. The Dypipe is equipped with an innovative test specimen insertion system that enables test specimen verification in live operation. This means that producers can be sure at all times that their production processes are working perfectly and do not lose any time for inspection when the system is at a standstill.

Another technology for increasing efficiency in the meat substitutes industry is the WPL-A automatic price labelling system. With its software and weighing and printing technology, this system not only enables the Display of live production data, but also the display of dynamic graphics of the freshly printed labels on the integrated 19″ Windows touchscreen. This ensures a Direct control over the labelling process and promotes transparency in the production chain. The system also offers the option of ERP connectivity and can be expanded with the e-mark software module to ensure seamless integration into existing operational processes.

The intelligent label design of the WPL-A fulfils the latest legal requirements for product labelling. No external software solutions are required as the system is equipped with native templates and formats for all printer configurations. The centrepiece of the WPL-A is its state-of-the-art weighing and compression technology, which is integrated in a compact design is accommodated. This enables high processing speeds, an increase in throughput and precise price labelling.

Visual inspection solutions are used at the end of the meat substitute production line. The VisioPointer is a solution for highly effective seal seam inspection of packaging in the food industry. By using hyperspectral analysis for coloured packaging or infrared for transparent packaging, the VisioPointer can even Detect the smallest leaks or irregularities in the packaging seal. This ensures product integrity and minimises the risk of contamination due to inadequate packaging.

„We offer our customers in the meat substitutes industry weighing and inspection solutions for the entire production process: from incoming goods to outgoing goods. From entry-level products to premium solutions. In addition to our high-quality systems, we also have intuitive software solutions in our portfolio that simplify recipe processes, reduce raw material waste and have sophisticated safety functions such as track and trace.“.

Lars-Henrik Bierwirth

The company offers the ProRecipe XT PC software for manual recipe processes, the Batch-PMS software is ideal for automated recipe processes and the SPC@Enterprise software provides customers with a centralised data management tool.

Source: Minebae Intec