With the „Flexabox“, SW-Paratus GmbH is presenting a shipping packaging at FachPack 2019 that grows with the customer. The patented packaging solution has a modular design and enables customised packaging of shipping goods. It can be dynamically loaded up to a weight of 600 kilograms.

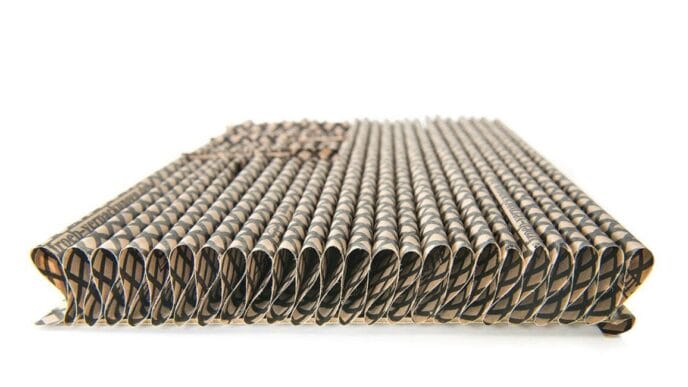

The basic structure of the system is the cardboard base onto which a Cardboard ring is placed. The required height is achieved with the help of stabilisers and additional rings. A lid closes the Cardboard box. The packaging can then be strapped or Stretch film be wrapped.

SW-Paratus emphasises that the Flexabox can be loaded and unpacked layer by layer. This guarantees a back-friendly Ergonomics at the workplace. Customers who rely on Flexabox also save money, Packaging material one. Only as much is used as is actually needed. The height-optimised, stackable cartons also significantly save storage space, as floor space in the warehouse and on the truck can be used optimally.

Compatible with all common pallet systems

The company from Hall in Westphalia sees many design advantages in the Flexabox system. In addition to its flexibility, this includes above all its compatibility with all common pallet systems. The safe Stackability in warehousing and forwarding operations and on lorries is guaranteed.

Also worth mentioning is the Ease of use, says the pallet specialist from East Westphalia: „In terms of operation, the system is self-explanatory. All the components are perfectly harmonised.“ Reusable and flexible, it also demonstrates its advantages as an internal load carrier.

[infotext icon]You can find out more about the SW-Paratus range on the Website of the company.

[/infotext]