Paper-based adhesive seals that can be processed at production speed? Does it really work? Yes, say various pharmaceutical companies after successful tests. This solution for the tamper-proof closure of folding cartons was developed by Vioprint from Turnhout (Belgium) and perfected until it was ready for series production.

As possible first-opening protection in the packaging of pharmaceutical folding cartons Three variants are usually used: tamper-evident labels, so-called adhesive seals, micro-perforated tear-open tabs or a tab seal. Adhesive seals are widely used because, in contrast to tamper-evident labels, attempts to open them are immediately recognisable due to damage to the label or box.

Whereas plastic was previously used for these labels (PE or PP), since last year the market has also had access to a Transparent paper-based variant available. This takes account of the concept of sustainability, as covering a carton with paper makes it easier to recycle and also reduces the consumption of new plastic.

A path with high hurdles

Statements about the „Green Deal“ and the more careful use of resources are omnipresent. However, the bar is set very high for practical implementation in the pharmaceutical production and packaging process. GMP requirements, qualification expenses and technical restrictions, coupled with high production pressure can slow down the willingness to innovate.

Now it was a particular challenge for most pharmaceutical packaging companies, Properties of TE labels in line with the requirements for packaging material, dispensing systems and production stability to bring. It was not uncommon for the labels to be everywhere but in the desired position on the box. Even renowned label manufacturers were only able to work on product maturity in the field, and the optimisation process tried the patience of those responsible for packaging.

(Image: Jan Hessing)

Variant made of translucent paper ready for series production

Vioprint also rose to the challenge of replacing plastic tamper-evident labels. The company is a Track&Trace sales support point for the German manufacturer Wipotec and also represents the Darmstadt-based manufacturer REA with labelling and verification systems. Bram Leys, owner of Vioprint, has been at home in the pharmaceutical packaging sector for over 20 years and is very familiar with the requirements there.

How did this come about? In 2019, Vioprint was approached by the customer Janssen, to work on a stable tamper-evident design - still PE-based at the time. This worked successfully, and the next step was to develop a more ecological version made of transparent paper at the beginning of 2023. The first version (Generation 1) was already so successful that Uhlmann Pac-Systeme also decided to show the TE-Eco labels from Vioprint to trade fair visitors on a production line at interpack in May 2023. „The Vioprint material was convincing, we had a stable run on our S500. All in all, a convincing performance,“ said Georg Schick, Strategic Product Manager Track & Trace, summarising the results at the time.

In this first generation, the labels were still applied to a paper liner. This meant that application speeds of just under 40 metres per minute could be achieved. In addition, the risk of tape breakage increased. The decision was quickly made, the paper label on a more stable PET liner as a carrier tape to use. With Generation 2 of the TE-Eco labels, there are now virtually no limits to the dispensing speed.

Production of TE-Eco labels

Production at Vioprint takes place on a modern rotary die-cutter. This means that 20 million labels can be produced per month. With a second machine production capacity to around 400 million labels per year from 2025 significantly increased. All components used come from direct European neighbours or predominantly from Germany. The punching plates, for example, are manufactured at the German headquarters of the manufacturer RotoMetrics. The wood used in the paper comes exclusively from FSC-certified cultivation.

The expertise lies primarily in the interaction of the following factors:

- the selection of an adhesive with a high initial tack in a defined coating thickness,

- The punching depth is precisely matched to the label material and the liner,

- the correct winding tension, which prevents the adhesive from bleeding.

Quality assurance measures go beyond what is customary in the industry. For example, the material is 100 per cent checked using a camera inspection and splices in the primary material are always cut out. Incoming goods inspection, batch-clean delivery with certificate and retained samples over a period of five years are standard procedures. The operating hours of the cutting dies are tracked and a consistently high level of quality is ensured by changing them in good time.

Sales in the DACH region are organised in cooperation with Jan Hessing Print&Control. The company was closely involved in the development processes and is known in the industry for its outstanding expertise in serialisation labelling and quality inspection.

Customised adaptations

Many customer requirements can be met with customised die-cut sheets. For example Implement centre perforation and safety punching in various geometries, although this is far less of an issue with paper than with the previous plastic-based variants. This is because the combination with the strong adhesive means that the tear behaviour and push-through resistance are much more homogeneous and predictable at every point.

The Application of multicoloured logos or even serialised data can be applied in a separate work step using the digital industrial printing system: Even so-called backside-numbering of the back of the carrier is possible. In addition to being used as a TE tamper-evident seal, the material can also be used as a closure label for booklets.

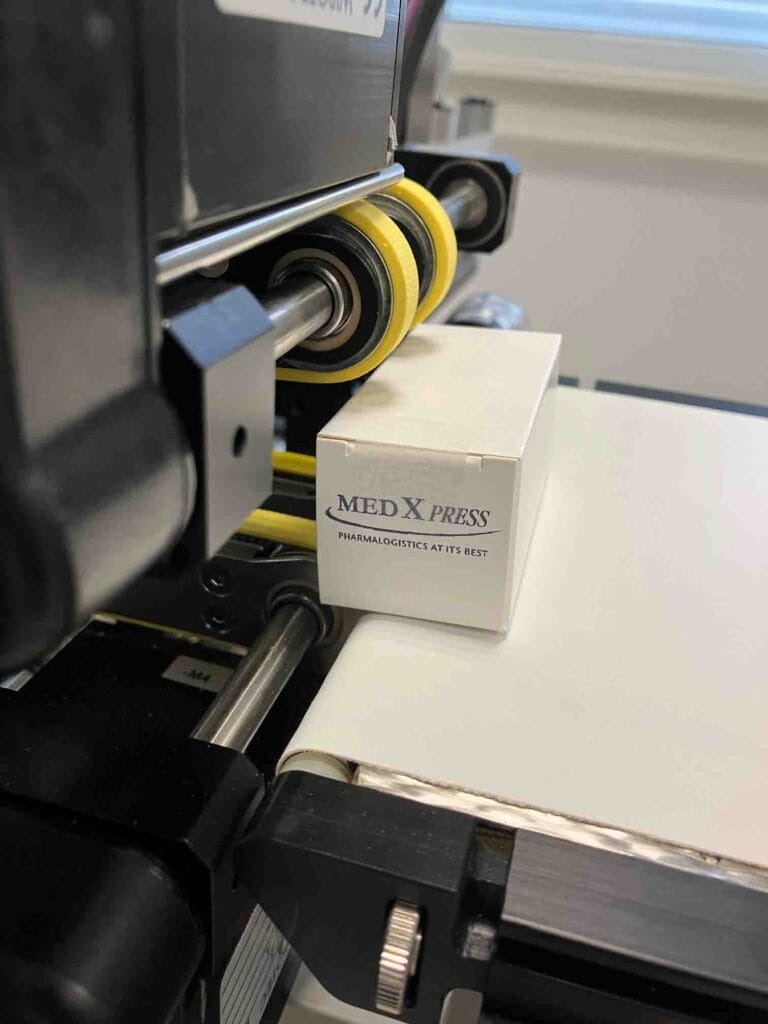

(Image: Med-X-Press)

Voices from the field

The Pharmaceutical logistics company Med-X-Press from Goslar has already put the sustainable TE solution into practice. The leading service provider for anaesthetic logistics in Germany uses the Vioprint solution: „We want to offer our customers added value at all levels of our service portfolio. This also means that we have our finger on the pulse when it comes to packaging. The new TE paper labels are part of how we can fulfil our commitment to sustainability,‚ emphasises Lars Dörhage, Managing Partner of Med-X-Press.

The Upper Bavarian manufacturer Optosol from Miesbach is also convinced. Optosol produces care products for contact lenses and fills sterile solutions as a contract filler. With Optosol, the new label jack from Kraus Maschinenbau takes over the double-sided dispensing. An interesting feature of this unit is the short set-up times when converting from side to upright flap labelling. „The new Eco labels run perfectly through the dispenser,“ says Alfred Hefft, owner and production manager at Optosol. „A new label variant plus an innovative new dispensing system - this allows us to react quickly to customer requests, even as a contract filler.“