Rea Elektronik will be presenting innovations in the field of non-contact direct marking of packaging and products, labelling and code checking. The Rea LabelTower - a co-operation project with Strelen Control Systems - will be presented as a complete solution for code and layout inspection.

Print directly on packaging, never again bring defective codes and incorrectly labelled products into circulation and thus reduce material diversity and error costs: Under the motto "Print - Apply - Verify", Rea Elektronik is bringing something new to the field of contactless direct labelling of packaging and productslabelling and code checking to Nuremberg.

The Mühltal-based company has also developed intelligent solutions for compliance and Implementation of the requirements of the new packaging law for material identification, the Recycling Ordinance and therefore also for the more sustainable use of resources.

New direct printing solutions for cardboard and film packaging

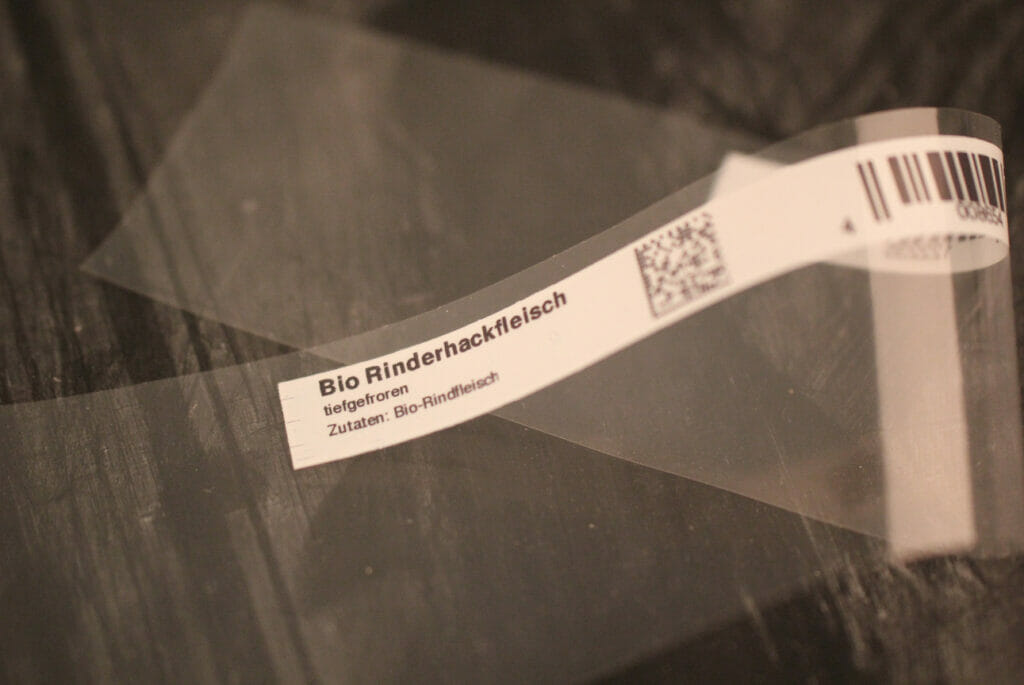

Rea has developed a new, non-contact direct printing technology for transparent or translucent film packaging in order to print codes and plain text with the required contrast. In a single work step, the system creates a white ink mirror and immediately writes on it with black ink. The colour mirror and lettering then dry together in a very short time. A patent application has been filed for this solution.

Right or wrong label?

Rea also presents innovations in the field of Optical inspection of codes and print content before. Unreadable or poorly legible codes, mixed-up labels or incorrect print content are the horror of every manufacturer. Players in the food industry, especially those in the meat and fresh produce packaging industry, are therefore well advised to closely monitor all labelling requirements. To ensure that the correct codes, graphics and fonts are applied to food packaging labels, the Strelen Control Systems GmbH and Rea Elektronik GmbH As a co-operation project, a complete solution for code and layout checking to.

Label inspection with digital image processing

The font recognition software Safe-Ident Label from Strelen is based on the latest technology. Artificial intelligence and machine learning processes for checking dates, product numbers, text and graphics on different types of packaging. The layout check quickly and reliably checks label data for presence, correctness, legibility and completeness. With this process, the products do not have to be checked inline. Instead, before production starts, the complete packaging of a product is placed in the Rea LabelTower inserted.

Due to errors, lack of contrast or poor quality, codes on labelled products are often illegible and cause enormous costs (e.g. for product recalls). The latest verifier technology from Rea has been integrated into the Rea LabelTower, enabling verification that the codes are correct and error-free. Rea will be presenting two new verifier variants in Nuremberg, which Be able to check codes inline or mobile or for code inspection on glossy surfaces.

Rea Elektronik at Fachpack 2021: Hall 1, Stand 228

Source: Rea Electronics