From wireless temperature monitoring solutions and active bags for the fresh fruit industry to sustainable alternatives for fruit, vegetables and fresh-cut food: Fruit Logistica offers a wide range of solutions for the fruit and vegetable industry, including some world and European premieres.

SoFruPak: Cardboard packaging with transparent lid

World premiere: The new SoFruPak Witold Gaj (Wola Krzysztoporska, Poland) premium packs are a further development of the SoFruMiniPak®-packaging. A new addition is a lid closure made of clear plastic. Three variants are available for 500, 250 and 125 gram contents. The cardboard tray and lid closure are supplied separately to agricultural producers. The lid can be placed on the carton tray either by hand or by machine. The SoFruMiniPak®-Premium packaging is designed for berries, stone fruit, tomatoes and mushrooms. The advantages include the fact that the new packaging stands out from other comparable products and that it is user-friendly for both packers and consumers. They have been registered for patent in the EU and the USA.

SoFruPak at Fruit Logistica 2018: CityCube Hall B, Stand A08

Christiaens Agro Systems: Automatic sorting of cucumbers

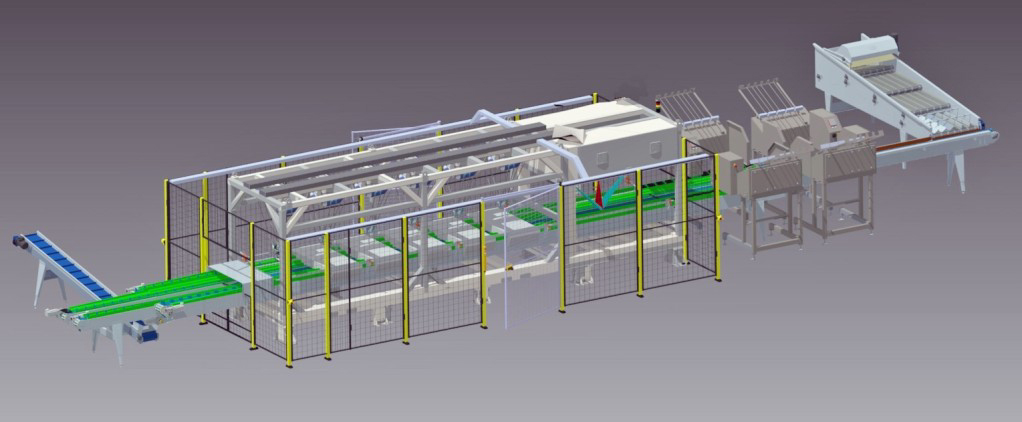

World premiere: The SortiFlex integrated packing robot from Christiaens Agro Systems BV (Neer, Netherlands), which specialises in sorting lines for elongated vegetables, makes it possible to sort, classify and pack cucumbers automatically. It was developed in co-operation with the expert companies Beltech, specialist in image processing technology, and ABI, manufacturer of high-end delta picking robots. The partners developed a new concept for sorting and packing cucumbers automatically and at high speed: This is done by a fully automated robotic system with the latest 3D image recognition and flexible robotic pickers. This sorting cell can pack cucumbers directly into several package types.

Christiaens Agro Systems at Fruit Logistica 2018: Hall 7.1a, Stand A05

Veripack: Compact and easy to stack

World premiere: Veripack Embalajes (Barbera del Vallès, Spain) presents its new DISTRIPACK packaging line®. The containers are compact, easy to stack, safe to transport, easy to store and easy to place on shelves. They are suitable for a wide variety of fresh ready-to-eat products such as loose berries or fresh-cut products. The Spanish exhibitor is presenting a wide range of the new shakers. There is a choice of nine different shaker sizes with hinged lids from 50 to 275 grams, which are easy to stack thanks to the rounded edges on the base and lid. The 200 and 250 gram versions are available with a lid with two hinges and a spout. The packaging material is made of clear PET and is recyclable. The lid and base are ventilated and there are drainage holes on the underside.

Veripack at Fruit Logistica 2018: Hall 5.2, Stand D05

Anacail: Better quality and longer shelf life

World premiere: The unique Anacail system from Anacail Ltd (Leeds, UK) utilises plasma technology to convert some of the oxygen in a food pack into ozone. Ozone is a fast-acting germicide that reduces spoilage organisms and pathogens on the surface of food and increases shelf life. The ozone decomposes completely into oxygen within minutes. Numerous advantages have been established in extensive tests. For example, the shelf life is considerably extended. Furthermore, improved fruit quality was observed throughout the entire shelf life. There was also less in-store loss and fewer customer complaints. The patented in-pack ozone generation can be integrated into a production line directly after the pack seal.

Anacail at Fruit Logistica 2018: Hall 10.1, Stand A15

Redpack: Iceberg lettuce in a flow pack

As a result of its collaboration with growers, Redpack Packaging Machinery (Norwich, UK) is presenting a solution that realises a tight pack for iceberg lettuce and also guarantees the required shelf life. The NTS-BMI flow-wrapping machine (pictured) developed by the exhibitor has numerous impressive features that ensure gentle packaging and prevent damage to the lettuce. For example, the special infeed consists of V-shaped belts that prevent the product from rolling away at high speeds or during operation in the field. During the transfer to the film, the iceberg lettuce is stabilised by a slat system and thus held in position. A further cost reduction is achieved by optional integrated printers and labellers for labelling during the packaging process.

Redpack at Fruit Logistica 2018: Hall 7.1b, Stand B02

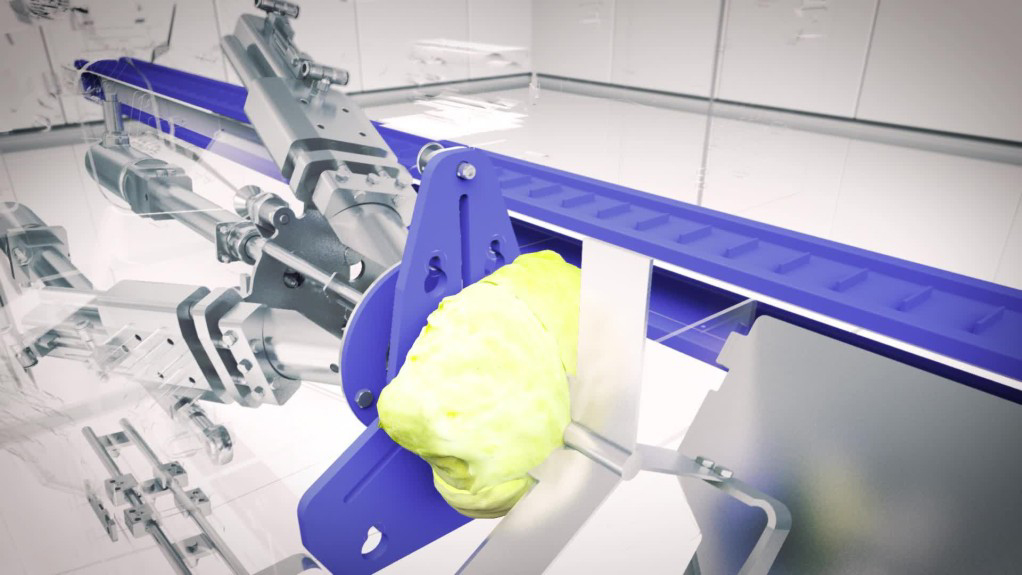

FTNON : Robotic decorating technology

FTNON Almelo B.V. (Almelo, Netherlands) has developed a robotic solution for the uniform arrangement of lettuce and cabbage, combined with 3D product data management. The CoreTakr scans the lettuce or cabbage in a scanning cabinet with five cameras, which together reconstruct a spatial 3D model of each head. A robot picks up the lettuce, rotates it and then places it in a precise and optimised position. The robotic systems can automate repetitive manual tasks in the fresh produce area in a safe and extremely hygienic way. They also generate a lot of useful information, e.g. raw material data such as size, colour, shape and damage, to identify all incoming products and inform the robotic decoring system.

FTNON at Fruit Logistica 2018: Hall 4.1, Stand D08

Carton Pack: Alternative to conventional PET containers

The CARTONPET tray is a sustainable alternative to conventional PET containers for fruit, vegetables and freshly cut food from Carton Pack Srl (Rutigliano, Italy). The packaging tray is made from an innovative material. Compared to normal PET, the material achieves very low specific weights, so that the packaging weighs up to half as much as standard packaging. The functional and mechanical properties of the CARTONPET tray correspond to those of PET containers. The new packaging material consists of 80 per cent recycled material. The bubbles in the core of the material enhance the cardboard-like colour. In addition, the material has a very smooth surface and creates a clear background. This ensures vivid colour reproduction during printing.

Carton Pack at Fruit Logistica 2018: Hall 21, Stand D02

Gruppo Fabbri: User-friendly and flexible

The new packaging machines in the Elixa Libra line from Gruppo Fabbri S.p.A. (Vignola, Italy) offer functions such as weighing, packaging and top & bottom labelling of fresh and ultra-fresh foods on trays without the need for compressed air. The result of a close collaboration with Espera, Elixa 24 and 35 Libra are specially designed for retail and small to medium sized packaging centres. Elixa Libra uses only the 280 millimetre roll width for all tray sizes and meets all of today's requirements for label configuration, barcode, weighing and data management integration with the customer's system, space requirements and performance, and Gruppo Fabbri provides full technical support worldwide for the complete installation, integration and service management of Elixa Libra.

Gruppo Fabbri at Fruit Logistica 2018: Hall 3.1, Stand D12

Pentaplast: Transport box with folding side panels

European premiereDue to high demand on the national and international market, Penta Plast Srl (Agata Feltria, Italy) has developed a new product: ECOBINS H.60 (Fig.). Like the H.80 and H.100 models, this variant also has an „eternal life“ according to the exhibitor. The boxes are fully recyclable and part of the recycling and reuse system. Thanks to the collapsible side panels, the costs for storage and transport when empty can be reduced by up to 66 per cent compared to conventional boxes, while maintaining the same load capacity and resistance. The ECOBINS box is stackable and is made from high-quality, yet cost-effective materials. It can be customised with different colours at the bottom and sides. For every three irreparably damaged parts, the manufacturer supplies a new box free of charge.

Pentaplast at Fruit Logistica 2018: CityCube Hall B, Stand D07

D+E Labelling fruit and vegetables

D+E GmbH, Neuwied, has further developed a natural process for labelling fruit and vegetables without the use of chemical additives, packaging materials or stickers. The new fully automatic EcoMark NB 3002 laser machine only removes the pigments from the outermost layer of the skin and has no effect on the quality or flavour of the food. Natural Branding responds to increasing organic specifications and increases productivity through automation. Both individual items and entire crates can be labelled. Labelling times from as little as 0.3 seconds per logo are possible. The new user-friendly software makes it possible to call up a different product setting with just a few clicks. This achieves optimum results and extends the shelf life of the products. Labelling is carried out in a continuous process without stopping. The type NB 3002 can be customised to fit into existing processes and therefore saves a lot of time.

D+E GmbH at Fruit Logistica 2018: Hall 10.1, Stand B08

Hans Klotz: Packed in a squeeze bag

European premiere: The new fruit and vegetable pouches (photo) from Hans Klotz GmbH (Bolzano, Italy) can be supplied in different squeeze bag sizes and packaging depending on customer requirements. All products are free from preservatives and industrial sugar. The various blends are available in both organic and conventional quality. The range includes various fruit and vegetable purees. Variants with cereals such as oats and spelt are also available as healthy snacks for on the go and in between meals.

Hans Klotz at Fruit Logistica 2018: Hall 2.2, Stand D06

Deka Plastik: Active MA-MH bag for fresh fruit

The Trendlife Gold MA-MH bag is, according to Deka Plastik Ltd Sti. (Istanbul, Turkey), the Trendlife Gold MA-MH bag is the first active bag of its kind in the world for the fresh fruit industry. It can release some nanomolecule-sized compounds into the modified atmosphere containing the fresh produce. Nanotech compounds released from the bag film into the atmosphere can react with excess water molecules released from the product. They are able to destroy excess water molecules and keep moisture at a certain level. Such bags can indirectly influence the development of rot by reducing the moisture inside. A special Trendlife Gold version has been developed to prevent the growth of pathogens and infections, especially during the most critical storage periods. Antimicrobial pockets can directly influence the development of putrefaction by releasing antimicrobial substances (image right).

Deka Plastik at Fruit Logistica 2018: Hall 26, Stand A04

URSCHEL: For the most difficult cutting applications

The new, compact Affinity Integra dicing machine has been specially developed by URSCHEL Deutschland GmbH, Ober-Mörlen, for the most difficult cutting applications in the food industry. It is ideal for cutting dried fruit, fruit and vegetables, cheese, meat and temperature-controlled frozen products. The optimal cutting process achieves high capacities and customised, precise cutting sizes. The food cutting area is completely separated from the drive components to maximise hygiene. The feed drum and spindle ensure a controlled flow (even of sticky or moist products) through the cutting tools. The disc thickness is infinitely adjustable. The distance between the cutting edge and the cross-cutting spindle can also be adjusted, which also increases the cutting quality.

URSCHEL at Fruit Logistica 2018: Hall 3.1, Stand C09

Blulog: Temperamonitoring every minute

World premiere: BluRoad is a wireless temperature monitoring solution. It is not only suitable for refrigerated transport on the road, but also for pallets, containers or refrigeration systems. The system from Blulog (Poznan, Poland), which can be customised to the user's requirements, measures and supplies temperature data every minute. It consists of data loggers that are placed inside the refrigerated areas, as well as a hub or gateway either in the truck cabin or directly in the warehouse or logistics centre. From here, the data is transferred to the cloud. In the event of temperature deviations, employees are alerted by text message and email. All data is also available in real time in an online app. It provides temperature reports in PDF format so that users can react quickly. BluRoad also has an optional lorry fleet geolocator that uses a GPS module or a 2G or 3G connection.

Blulog at Fruit Logistica 2018: CityCube Hall B, Stand E14

You can find more information about the trade fair in our article FRUIT LOGISTICA 2018 - Fruit and vegetable marketing.