REA Elektronik will be showcasing coding and marking solutions for the plastics processing sector at K 2022. The solutions in the REA Jet product line enable process control, clear identification of materials and seamless traceability.

Where previously any attempt to leave permanent markings on extruded surfaces with water-based inks failed, today the diverse range of inks from REA Jet with more than 500 standard and special inks for excellent labelling results, even on complicated surfaces. In addition, all REA Jet systems can be operated with the standardised REA Jet Titan platform. The saves time and costs thanks to a lower error rate, reduced training requirements and easier staff deployment. And now also for applications beyond the application of logos, codes and fonts.

The REA Jet HR inkjet printer focuses on non-absorbent and difficult-to-mark surfaces, such as extruded plastic pipes and profiles and plastic packaging, High-resolution labelling with the best adhesion and legibility with the shortest drying time. Depending on the size of the motif, up to four print heads can be combined and markings up to 50.8 millimetres high can be applied. Alphanumeric texts and logos and variable information, such as date, time, counters, shift codes and database content, remain attached to the plastic part for its entire service life.

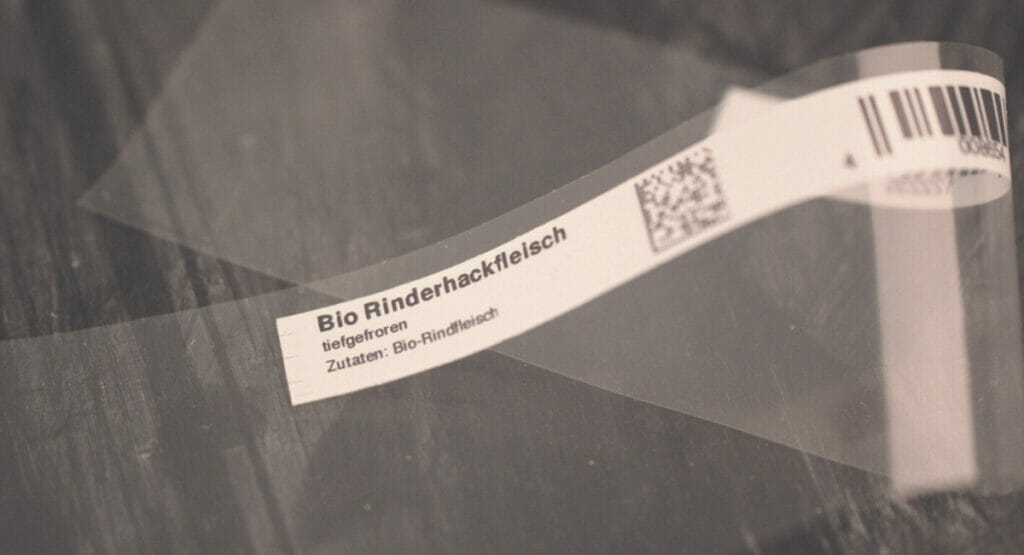

Even for surfaces that are difficult to label the inkjet printer saves the user from having to apply labels and the associated logistics and warehousing. Using the innovative wet-on-wet printing process, it reliably prints machine-readable codes and plain text inline on smooth, transparent and dark surfaces. The inkjet printer, which is equipped with a double print head, first prints a white ink mirror, which it then immediately writes on with black or coloured ink. Both then dry together.

For his proven HR technology, REA Elektronik now has another field of application The REA Jet HR has opened up a new area of application: the precise application of functional chemicals using digital printing. The REA Jet HR prints transparent plastic parts, which are only suitable for laser welding to a limited extent due to their limited light absorption capacity, economically and precisely with the Clearweld Primer. The primer subsequently absorbs the laser energy and enables reproducible, more cost-effective and better welding results.

Using only the power of light, the REA Jet FL fibre laser creates all kinds of variable data markings, codes and labels. On It sets plastic pipe surfaces or plastic parts from injection moulding production by changing the colour., The product is also characterised by its captive markings, which remain on the product for its entire service life and serve to ensure its traceability, partly thanks to incorporated laser-sensitive additives. With its compact design, the REA Jet FL can be integrated into any environment.

The company will also be exhibiting the REA Jet FL fibre laser integrated into the laser processing cabin. Your versatile concept and the autofocus function enable precise adjustment to customer requirements - from stand-alone manual workstations to fully automated networked marking stations, from the size of the process chamber to the laser power and positioning of the labelling field to the way in which the material is fed in and out.

Source: REA Electronics

REA Elektronik at the K 2022: Hall 4, Stand C22

More news on labels and labelling

CCL Industries expands labelling expertise

Perlen gets into moulded fibre packaging

Autajon Group strengthens presence in the Netherlands

Volati takes over Interket Group