Safety and security are key components of all future technologies today. Pilz, the automation expert with safety as its core competence, is inextricably linked with both terms.

The company not only focuses on all aspects of safety, but also continuously scrutinises them, thereby shaping the safety technology of tomorrow. When Hermann Pilz ventured into self-employment in 1948, the development from glass apparatus construction to electronics was still written in the stars.

Since its beginnings, machine work has been associated with potential dangers for people. What was missing was safety in and around the workplace, i.e. the machine. Today, humans and machines complement each other and are increasingly working hand in hand - and more safely - on the road to Industry 4.0. Security always plays a central role. It is important to distinguish between two safety concepts: The protection of people and the environment from machines, for which the English term „Safety“ and the protection of the machines and systems themselves, including their data, i.e. „security“. This is why the topic of security is already flanking every future technology today.

Milestone in safe automation

The industrial history of safe automation has a concrete starting point: in the post-war years in the Swabian region near Stuttgart, where Hermann Pilz 1948 with a Glassblowing and the production of Mercury switching devices laid the foundation stone for an innovative family business in today's Ostfildern-Nellingen: with mercury switching devices, which were the basis for the industrial switching devices to come.

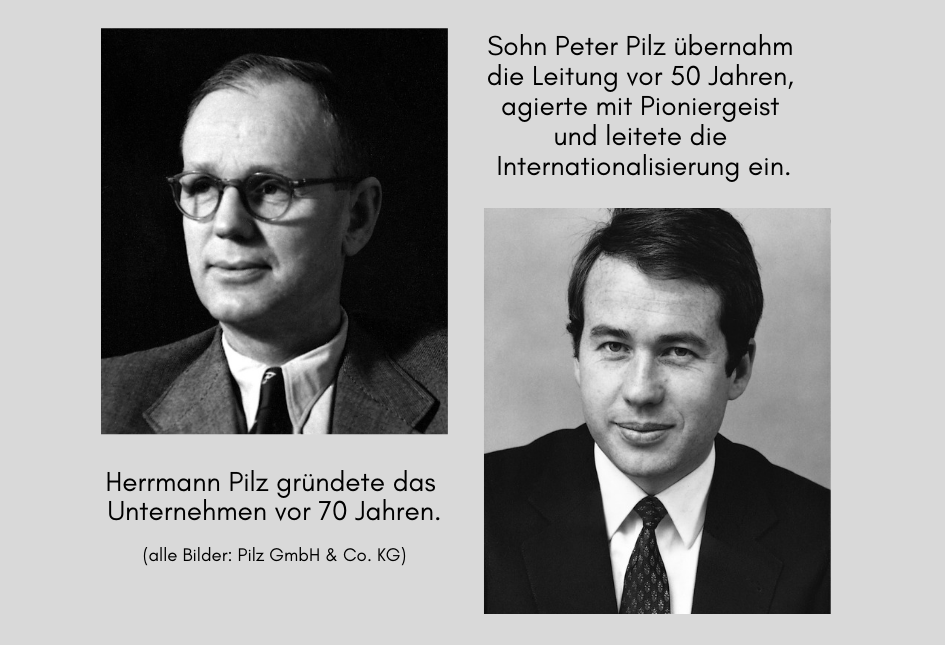

Already at this point in the company's history, his son Peter Pilz whose pioneering spirit would decisively drive the metamorphosis from glass apparatus construction to electronics. He took over the company in 1968 and immediately initiated targeted internationalisation. In the 1970s, too, expansion is the measure of all things. In addition to electronic control and monitoring devices, programmable logic controller systems are now also manufactured and sold. The innovative Swabians also set standards by standardising electronic components.

Patented safety switching device

Taken for granted today, but an important technical breakthrough in 1970: the Two-hand relay for presses. The operator could only use it to operate the machine because he had to use both hands outside the danger zone to operate it.

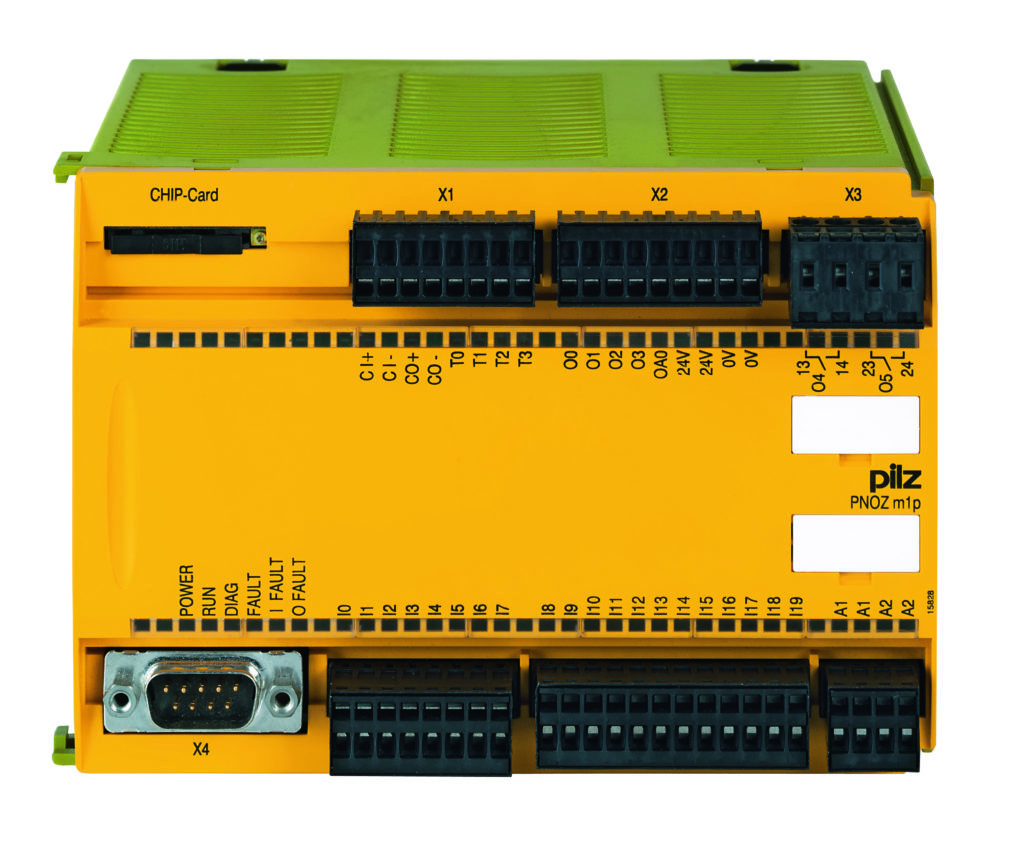

The relay is regarded as the forerunner of an invention that has been making plant and machinery safer all over the world ever since: in 1987, Pilz launched the first emergency stop relay. PNOZ onto the market. The abbreviation PNOZ, which has become a generic term worldwide, stands for Mushroom emergency stop forced guided. The patented safety switching device stops machines reliably and in a controlled manner in the event of danger.

Even from today's perspective, many automation experts categorise it as a „ground-breaking invention“ for automated production processes and it is practically synonymous with safety worldwide. With this stroke of genius, Pilz Initial provider on the global market and European market leader within a few years.

Ambassador of security

The entrepreneurial personality Peter Pilz did not live to see his big breakthrough. He died in an aeroplane crash in 1975. However, his wife Renate continued his life's work and joined the company as Chairwoman of the Advisory Board. In 1995, she took over the management of the company. In the same year, the The world's first programmable safe control system the world's first secure bus system in 1997.

„Security provides protection for personal well-being as well as for any economic endeavour. This is particularly true for automation, because every development here always creates new framework conditions,“ explains Susanne Kunschert, who, together with her brother Thomas Pilz, took over the management of Pilz GmbH & Co. KG in Ostfildern from her mother Renate Pilz at the beginning of 2018. (Image: Pilz GmbH & Co. KG)

„As an ambassador for safety, Pilz has the goal of ensuring the safety of man and machine worldwide,“ says Susanne Kunschert, summarising the task of the „Experts for safe automation“. The granddaughter of the founder and current managing partner has been with the company since 2002 and is responsible for Human Resources, Finance/Controlling, International Sales, Product Management, Marketing and Customer Support.

The company is currently represented by 42 subsidiaries worldwide, and the number of employees has risen from an initial 400 to around 2,400 today. In 2017, the Pilz Group generated a global turnover of 338 million euros.

From electromechanics to electronic solutions

Like most genuine innovations, the safety switching device that is still the most frequently used in machines worldwide initially had to overcome a few hurdles. Just like the First freely programmable control system PSS 3000, which Pilz launched on the market in 1995. Since then it has been possible to use electronic control systems in safety technology for the first time. Pilz had negotiated hard at national and European level so that software-based functions could find their way into safety technology. Legal requirements had previously prevented this.

With PSS 3000, Pilz not only internalised the basic principle of safety control, but also the criteria of safe automation. In this way, the company broke completely new ground in the mid-1990s: from electromechanics to electronic solutions for safety-related applications, which now also offered diagnostic functions. With the development of the first safe bus system SafetyBUS P, Pilz went one step further and in 1997 created a Decentralisation of safe control technology and the Transmission of security-relevant data possible. And this was already the case in the 1990s.

Sounds like the basic features of Industry 4.0 digital networking? Not by chance. „Safe control technology has fundamentally changed the world of automation,“ explains Susanne Kunschert.

Thinking early in the direction of Industry 4.0

When everything communicates in a decentralised manner, the need for secure communication increases. The protection of production data, expertise, access, integrity, products and against plagiarism are therefore added to the existing requirements as new objectives worthy of protection. Or to put it another way: Safety and security are the enablers of Industry 4.0 today. They are an inseparable pair of concepts when data flows through processes in digital form and opens up new functions through intelligent networking.

Pilz often anticipates such new safety requirements in its developments. „We have always spotted trends early on and supported them with our safety expertise,“ says Susanne Kunschert. „It is our declared philosophy and also our business strategy, to take up and pursue innovative ideas.“ To achieve this, Pilz invests around 20 per cent of its turnover in research and development every year - an above-average figure.

Special concept for success

Trying out new things and developing existing ideas further is part of Pilz's recipe for success. One example is the integration of basic concepts such as modularisation and multi-master structure into the controllers of the automation system PSS 4000. The approach: Intelligence must move locally into the control of a machine, so that a system remains in operation when a module or a new function is switched on or off. This is what makes Industry 4.0 applications possible.

„Intelligent networking is a great opportunity for the industry. Lean production achieves optimum plant utilisation. Individualised products can be manufactured under mass production conditions,“ says Susanne Kunschert.

All of this requires a basic understanding of security that does not end with the formulation of a business purpose. „Security must be lived in order to grasp the various dimensions of the need for security,“ says Susanne Kunschert. This can also be found at Pilz in the Motto „Safety for people, machines and the environment“ again.

Generation change: confidence in the future

Security creates trust, also in the future and in every relationship. It is therefore not surprising that the generational change at Pilz last year did not result in a break (in trust). For over 20 years Renate Pilz and shaped the development of the family business.

A personality who, despite his wide sphere of influence in business and society, does not cast a shadow over his successors. On the contrary. The owner family has not only prepared the generational change over a long period of time. They live a corporate culture that, even from an external perspective, can be described as togetherness. Mutual respect and openness are clearly not leitmotifs formulated in a one-day workshop in Ostfildern, but an expression of an inner attitude that is lived out in flexible, responsive structures. Where Appreciation It is well known that ideas can only really unfold when they are felt.

Safety and packaging go hand in hand

The concrete realisation of ideas, namely the solutions from Pilz, are Universally applicable. At the same time, however, they fulfil the primary requirements of a particular industry. Like the packaging industry. Production needs to pick up speed, merge with the IT world and fulfil individual customer wishes. And the issue of safety for man and machine also plays an important role in the packaging industry. highly automated packaging industry plays an important role. Between the small stand-alone machine, which packs components in film and is loaded by an operator, to the fully automated system, which packs food ready for dispatch in three cycles every second, there is a broad spectrum that Pilz has its sights firmly set on.

Globally standardised philosophy and quality

Pilz is active worldwide and the philosophy is the same everywhere: whether in Europe, Asia, North or South America.

„Customers understand the systematic and modular design of our systems, we understand our customers“ requirements. We know the country-specific standards and requirements and adapt quickly to economic and technical changes," explains the managing partner Thomas Pilz, who is responsible for IT, purchasing, research & development, quality management and production.

In this way, the traditional company ensures that with safety and international conformity assessment customers achieve advantages in global competition, especially if they export their (packaging) machines.