The introduction of paper pouches and a boom in sales prompted Swiss pasta manufacturer Pasta Premium to invest in its process technology. Three new packaging lines were equipped with multihead weighers from Ishida. The scales impress with their flexibility in processing short pasta products and small batches.

For the sake of the environment, the Swiss company Pasta Premium AG now markets its Bschüssig brand pasta in paper packaging. The changeover in packaging and the explosion in demand made it necessary to install two new packaging lines for short products and sprinkles. „The pasta was to be dosed and filled using multihead weighers from Ishida because we had had very good experiences with some of the machines we had purchased second-hand from this manufacturer,“ explains Simon Hofer, Head of Technology at Pasta Premium. Reliable technical support was provided at the time by Itech AG from Rotkreuz, the Swiss Ishida representative, which was subsequently commissioned to design a packaging solution.

Specified for the application

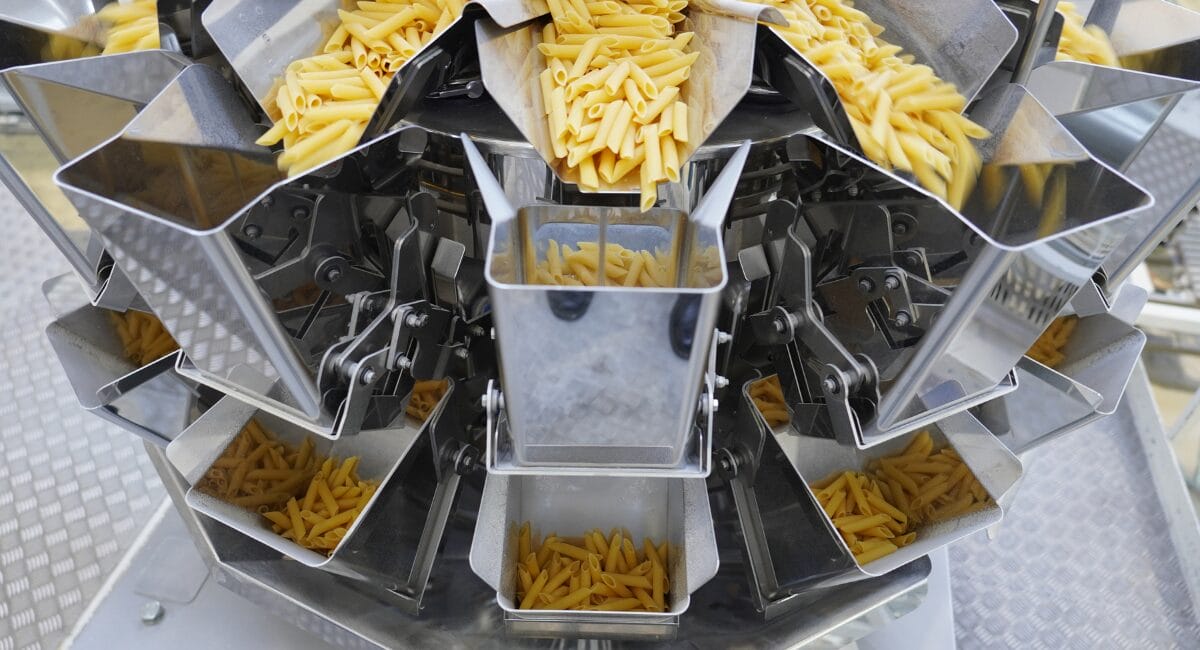

The experts at Itech installed a multihead weigher from the CCW-RVE Enhanced series for weighing the short pasta products. This 14-head weigher was customised by Ishida as standard for free-flowing, dry products such as small pasta products: It achieves convincing accuracy at medium and high speeds. Pasta Premium processes filling weights from 450 to 1,000 grams with this type of machine.

The short pasta products are fed through a hopper onto the distribution plate of the scales. A weighing cell regulates the feed quantity and individually controllable vibrating radial chutes continuously convey the product to the pre-shells. The double-opening and tightly closing tray flaps prevent even very small pasta from slipping out of the trays, which would impair the dosing accuracy. In fractions of a second, a microprocessor calculates the combination of portions that comes closest to the target weight. A five-stage digital filter of the weighing signal enables an accuracy of 0.1 grams. The pasta is then filled directly into the paper bags. Pasta Premium currently achieves a speed of up to 35 cycles per minute and the weigher could work even faster. On average, the overfilling per bag is just one gram.

Protection for fragile items

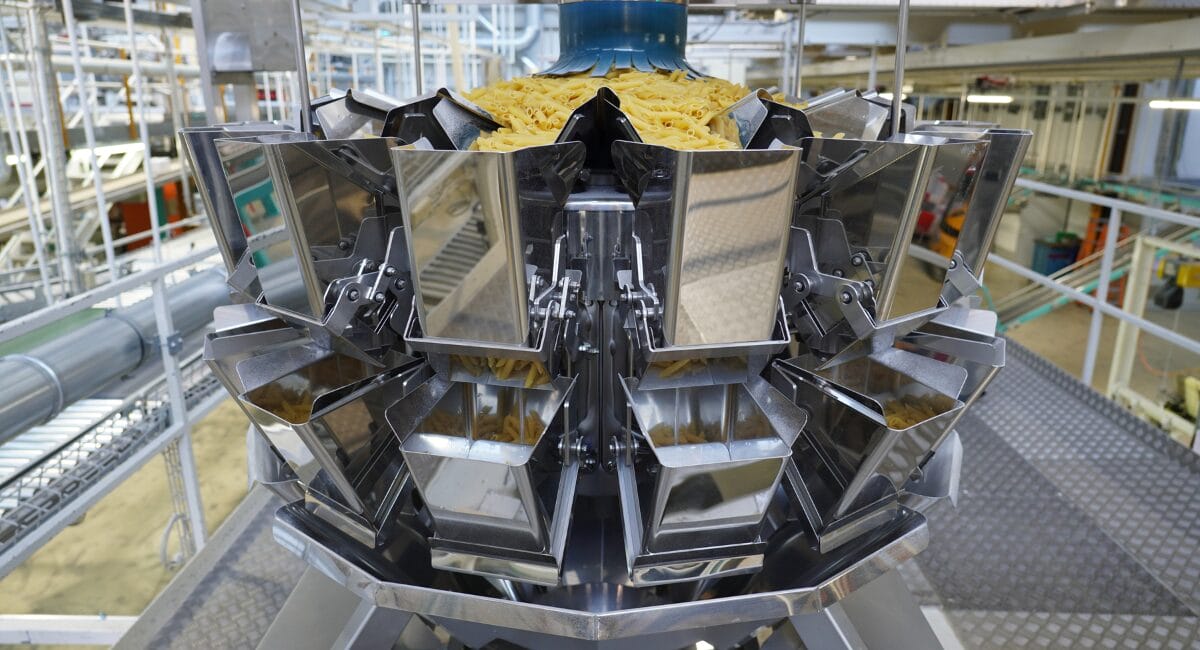

A second CCW-RVE-GS multi-head weigher is intended for sensitive scattered products. Products such as tagliatelle or pasta nests are packed in bags with filling weights of between 450 and 1,000 grams on this 14-head machine. Ishida developed this multi-head weigher specifically for the high-performance and gentle weighing of fragile food products. Its design features include minimised inclines, flat angles, low drop heights and individually opening pan flaps. Thanks to these features, the delicate pasta products glide gently through the weigher and product breakage is minimised. The speed is up to 28 cycles per minute and the dosing accuracy is also one gram.

Fast processing of small batch sizes

(Image: Pasta Premium)

The new lines for packaging pasta in paper bags are now mainly used in two-shift operations. „All multihead weighers are characterised by their high reliability and availability, and maintenance requirements are minimal,“ reports Simon Hofer. The flexibility of the scales is a major advantage.

„Our company specialises in small batch sizes, which means we have to make a lot of things possible in a very short time,“ continues Hofer. The scales favour the frequent changes between over 100 product variants because the changeovers can be carried out quickly and easily by calling up presets. In general, the machines are very easy to operate and the cleaning process takes very little time.“

Successful on the market

Pasta Premium also invested in a packaging line of the same type for paper bags as a replacement investment for an older line for short pasta products, which was also equipped with a CCW-RVE Enhanced multihead weigher. The company is very satisfied with its investment in packaging technology. „The multihead weighers help us to produce small batch sizes efficiently and secure a niche for ourselves in the highly competitive pasta market,“ says Simon Hofer. „The longevity of the scales and the long-term availability of spare parts also fit in with our sustainable corporate culture.“