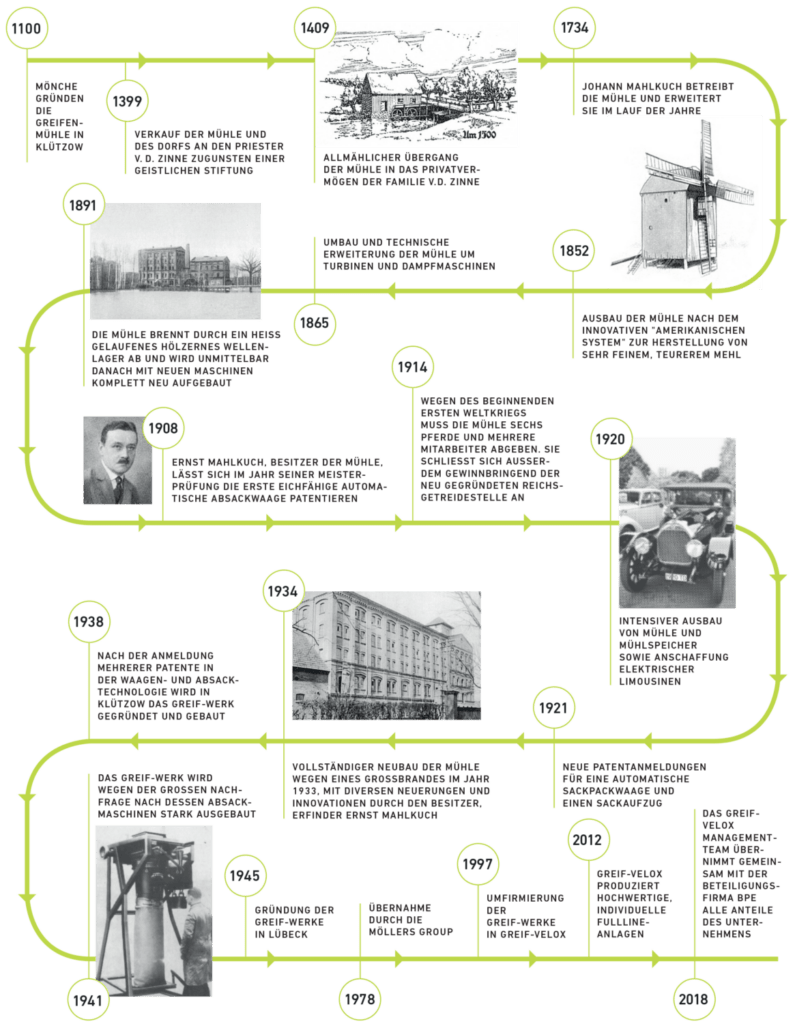

The Greif Velox story begins with one of the oldest documented companies in the world. The development from the Greifen mill to today’s global leader in the field of bagging light materials can be traced back more than a thousand years. The special feature: The full lines which focus equally on the processing of solid and liquid products.

This is something quite extraordinary: the history of Greif-Velox begins more than a thousand years ago with the founding of the Greifen mill by monks in Klützow near Stargard in what is now Poland. Today, the company operates as a developer of innovative and effective bagging and filling systems as well as full lines for the food, chemical and petrochemical industries and is thus firmly anchored in the packaging industry.

In the 18th century, the mill came into the possession of the Mahlkuch family, who over time, steadily expanded and innovated the business – from the installation of turbines and steam engines to the expansion into the then novel „American System“, which served to produce very fine, high-quality flour. By the end of the 19th century, in addition to flour production, the focus increasingly shifted to its bagging.

Several generations later, Ernst Mahlkuch founded the Greif factory in Klützow in 1938 on the basis of technologies he had developed in the bagging sector. His great inventiveness was remarkable: as early as 1908, he patented the first calibratable automatic bagging scale, which was later christened „Velox“ which comes from the Latin term for „quick“ or „fast“. With his developments, Mahlkuch was responding to the needs of users. With the new patent, they could not only weigh and fill their product more accurately but also save a great deal of time. „Better, faster, more rational is the Velox“ was an advertising slogan from the 1940s. Here, the machine’s focus was already on added value for customers: the „Velox“ as well as the „Paradox“ centrifuge, also patented by Mahlkuch, are still well-known in milling circles today.

On the way to becoming a full-line specialist

Due to the high demand for the novel bagging solutions, the factory was expanded as early as 1941 before Mahlkuch established the company as the Greif-Werke in Lübeck four years later. To this day, the company has its headquarters at this location. As early as the 1950s, Greif-Werke was developing market-driven solutions for bagging products. The Möllers Group, under the umbrella of Möllers Maschinenfabrik which specialised in filling and packaging systems, took over Greif-Werke in 1978. The managing directors at the time expected new synergy effects from this.

„Over the years, we have developed more and more into a company that offers not only packers, but entire lines to meet the demands of customers,“ explains Ralf Drews, the current Managing Director. In the following years, highly specialised functions such as bag sealing, palletising or load securing were increasingly integrated into the systems and finally made Greif-Velox one of the leaders in the full-line sector. As early as the mid-1980s, vacuum technology for bagging in valve bags was also developed.

Since 1997, the company has donned the name, „Greif-Velox“, which is still in use today and refers to two important historical milestones in its history: the original Greifen mill and the famous bagging scale from Mahlkuchs, which laid the foundation for the company’s orientation in more recent times.

In 1999, the company, Logdos, one of the market leaders at the time in the field of filling and dosing systems for liquid and viscous products, was taken over and the product portfolio expanded. „There are many customers, especially in the chemical sector, who produce both liquids and powders,“ says Drews. „By expanding the product range, we can offer them more portfolio within the same industry segment in similar applications with the same value context.“ To date, this has clearly set the company apart from its competitors worldwide, who typically serve either the liquid filling or powder bagging segment.

The machines also testify to a robustness that allows the company to stand the test of time. „This longevity is extremely important for our customers,“ Drews explains. „Because the connection between us and the customers often lasts longer than the average marriage in Germany, as the machines work reliably for 20, 30 or more years. That’s why it’s important that our customers can rely on us not only being present and finding the right solutions for them now, but also in the future.“

Greif-Velox has demonstrated this future viability anew in recent years: in 2018, the company separated from its previous parent company, Maschinenfabrik Möllers. The management team and an investment company took over all shares in the company. „This gave us the necessary freedom to grow further,“ says Drews regarding his company, which today employs more than 150 people.

Smarter Packaging

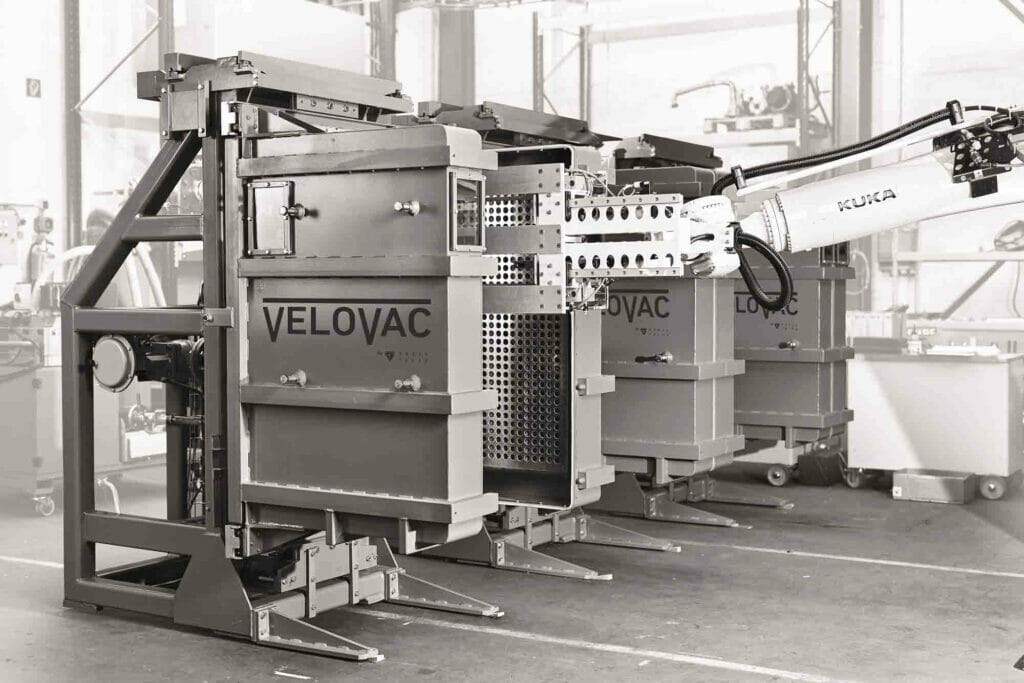

Values such as efficiency, innovation and reliability („EIZ“ for short) have fundamentally shaped Greif-Velox to this day. This philosophy is deeply anchored in the company’s DNA, combined with the incentive to design plants in a solution-oriented and particularly efficient manner. The realignment since 2018 has been accompanied, among other things, by focused support for the research and development department in order to further advance innovations such as the VeloVac-FIBC for bagging in the light materials sector and smart industry applications.

First launched in 2021 as the VeloVac-FIBC by Greif-Velox, it is now called the VeloVac-XL. It can bag ultra-light powders such as carbon black and silica, dust-free and efficiently into Big-Bags. For years, the Research and Development department in Lübeck had been working on this product, which is now going into practical use. There, it helps to solve problems that have long existed in the industry and offers up to 400 per cent compacted bags without product loss and without contamination.

„Enormous innovation potential is usually derived from unsolved or only moderately well-solved customer problems,“ says Ralf Drews, the company’s managing director. „Proactively, we create solutions for these customer problems, which usually always translates directly into productivity increases for the customer. These include, for example, better quality, time and money savings or an improved appearance.“

„We have enough innovative products. Now, the next logical step is to find a way into the world so that even more customers can benefit from our products,“ says Drews. The establishment of further sales partners and channels worldwide as well as the foundation of an American subsidiary in 2020 have also been implemented. This growth strategy is also to be consistently implemented internally. In addition to the expansion of the production areas, Greif-Velox is therefore focusing on a future-oriented orientation. „I am convinced that there is still a lot of room for innovation in the world of our customers,“ Drews summarises.