Labels offer a wide range of functions: They provide information, enable identification, promote organization, support branding and ensure compliance with regulations. All too often, these functions are lost due to unintentional or even willful label removal. Label and carton processing companies in the packaging industry can have their products assessed for durability, stability and tamper evidence.

Whether smooth, textured, porous or flexible: in general, different types of surfaces require suitable adhesive properties to ensure the integrity of the labels over their service life. Some users place particularly high demands on the material combinations to be used. Product protection is an explosive example of the necessity of a label’s function. In various industries, such as pharmaceuticals or cosmetics, this requires packaging to be equipped with first-opening protection. In the case of prescription drug packaging, for example, label-carton laminates must meet the highest quality standards in order to protect the packaged products from tampering and thus the safety of consumers. An anti-tampering device (ATD) is intended to provide an unmistakable indication of whether a folding carton has been opened or tampered with as the outer packaging of a product. Without this security feature, the individual coding (Unique Identifier) for checking the authenticity of the product is worthless, as the contents of the packaging can be altered in an uncontrolled manner.

Problems in the industry

In a global market in which products are constantly exposed to different environmental conditions and mechanical stresses, for example, during storage or transportation, ensuring the stability and ageing resistance of label-cardboard laminates is a key aspect that needs to be verified using targeted test methods.

These include adhesion tests, accelerated ageing tests, exposure to environmental conditions such as moisture, temperature and UV radiation as well as resistance and tampering tests. These tests enable label users to evaluate the behaviour of the materials or the composite under real or simulated conditions and to identify potential weak points before processing their products. For this purpose, the Research Foundation of the Paper Industry provides practical testing facilities to evaluate the durability of labels on different substrates.

The potential of the review

The requirements for the label-cardboard laminate are primarily determined by the intended use. Based on this, various relevant criteria for functionality are evaluated as part of the test methodology:

- stability and irreversibility of the bond between the label and the cardboard surface: The label must not come loose or fall off automatically or as a result of real environmental influences.

- Visibility of any tampering: The removal of the label from the surface must leave visible traces in the form of line removal or fibre tearing. In the case of special void labels, the coloured pigmentation should remain on the surface of the packaging and not be removable without a trace.

- maintaining elasticity during the service life: The label material must not become brittle so that perforations attached to the label in particular do not break without external influence.

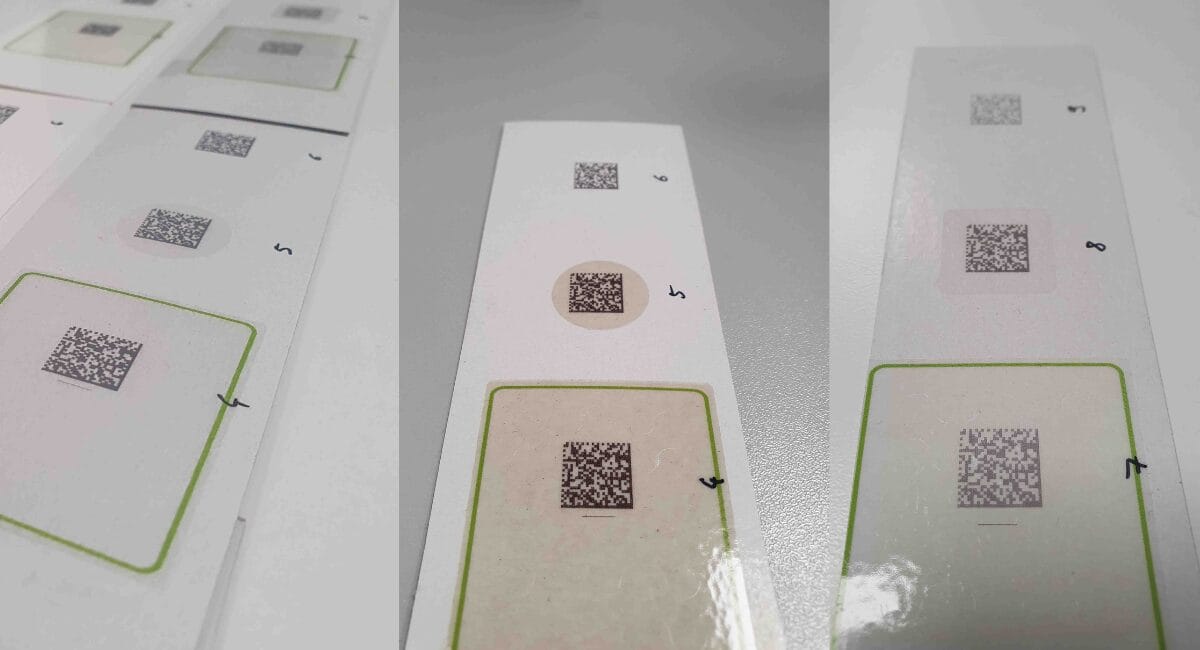

- colour stability or preservation of transparency: The label-cardboard adhesive bond as a whole must not discolour in such a way that this leads to problems with the legibility of the unique identifier (UI).

Test methodology at a glance

To test the durability and stability of label-cardboard laminates, the method includes a defined peel test of the unaged and accelerated aged laminates with subsequent evaluation of the fracture pattern.

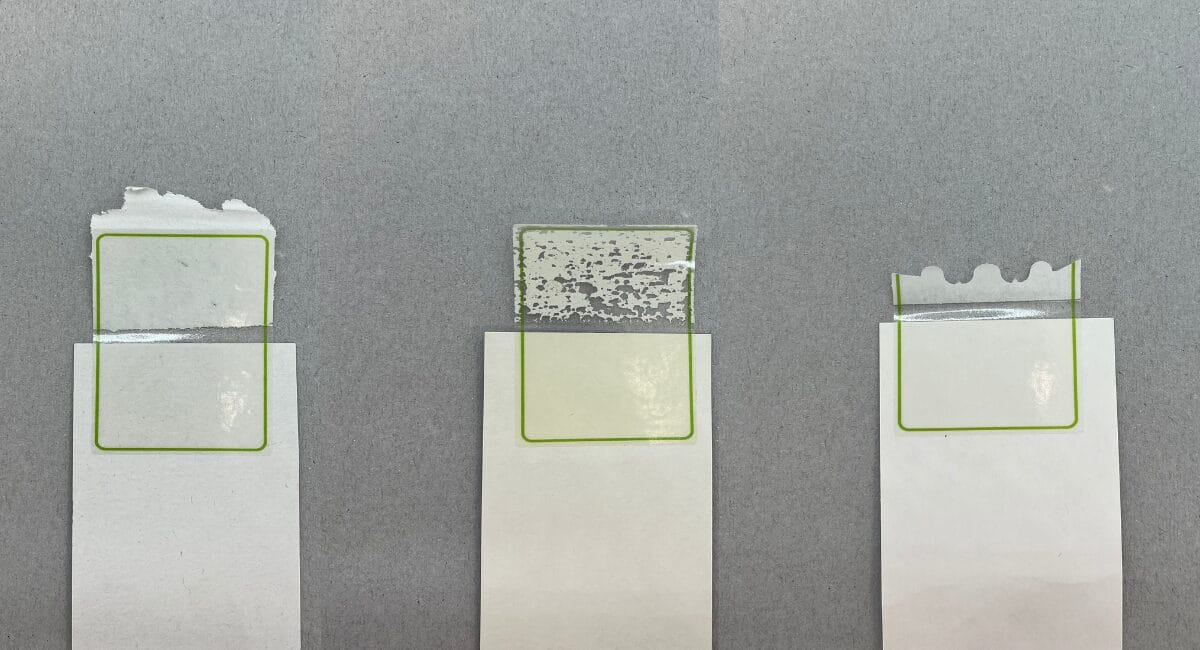

The overview shows examples of breakage patterns for three different adhesive bonds. If the splitting strength of the cardboard is lower than the adhesive strength or the strength of the label, breakage pattern A can be observed. If the line adhesion to the cardboard surface is lower than the adhesive force or strength of the label, breakage pattern B is observed. In example C, the label itself fails because the adhesive forces exceed the strength of the label perforation.

However, it is not only mechanical strength that plays a role in the application of label-cardboard laminates to packaging. Different environmental influences and ageing processes can have a greater or lesser impact on the optical properties of packaging fitted with labels. In addition to purely aesthetic requirements, the legibility of important information for various applications is essential. This must not be altered by ageing and environmental influences to such an extent that data matrix codes, for example, are no longer readable.

How tamper-proof is the product?

Tamper-proof packaging is not only highly relevant in the pharmaceutical sector. The right combination of folding boxboard and label is essential when it comes to ensuring that a product is tamper-proof. As part of a research project, the Research Foundation of the Paper Industry (PTS) has developed tampering tests and underpinned them with an intuitive evaluation scheme. The evaluation is based on the manipulation result and the manipulation effort. The traffic light system introduced shows the degree of difficulty of the respective manipulation attempt at first glance. A label-cardboard adhesive bond that can be easily separated by hand without leaving traces of tampering is classified as RED (a.). The classification GREEN (c.) generally indicates an adhesive bond that is difficult to manipulate.

Implications for practice

The methodical approach to evaluating label-cardboard laminates helps companies to adapt new product developments to the relevant application in a time- and cost-efficient manner and gives potential users an impression of the expected functionality even before the product is used. Significant gains in terms of increased sales and cost savings can be expected.

The test results also offer companies the opportunity to make a qualified material selection and reduce complaint rates in the long term. In addition to a reduction in rejects, this also leads to resource savings in terms of energy, materials and personnel capacities. Companies can significantly reduce cases of damage.

Label-packaging combinations that cannot be tampered with offer security for suppliers and buyers, for example in the case of pharmaceutical packaging, packaging for high-quality cosmetics, but also for cost-intensive electronic devices. An exchange with counterfeit goods is prevented or a corresponding attempt at fraud is made visible. According to a press release from the European Union, counterfeit medicines cause an estimated Europe-wide loss of around 10.2 billion euros. The loss of sales due to counterfeiting amounts to 4.4 per cent of all legally sold medicines in the EU.

Even non-willful detachment of a label from packaging can lead to high amounts of damage. PTS has already analyzed various complaints in the past in which the combination of label and packaging was not matched to the intended use. For example, the labels on meat packaging from the chiller cabinet came off. In another case, more than ten combinations of label and corrugated cardboard materials were submitted for testing, in which the label labelled around the corner detached from the corrugated cardboard.

There is a need for quality-oriented selection not only of labels and cardboard but in principle of all materials to be affixed with a label. This PTS methodology is not only of interest to all companies in the label manufacturing and converting industry but generally to all sectors in which labels are used, whether as product protection, information or advertising media.