In a laboratory experiment at the Royal Netherlands Institute for Marine Research, it was proven that the bacterium Rhodococcus ruber eats and digests plastic. Especially for dealing with plastic in the world’s oceans, the bacterium could be part of the solution.

Based on a model study with plastic in artificial seawater in the lab, PhD student Maaike Goudriaan calculated that bacteria can break down about one percent of the fed plastic per year into CO2 and other harmless substances. „But,“ Goudriaan emphasizes, „this is certainly not a solution to the problem of the plastic soup in our oceans. It is, however, another part of the answer to the question of where all the ‚missing plastic‘ in the oceans has gone.“

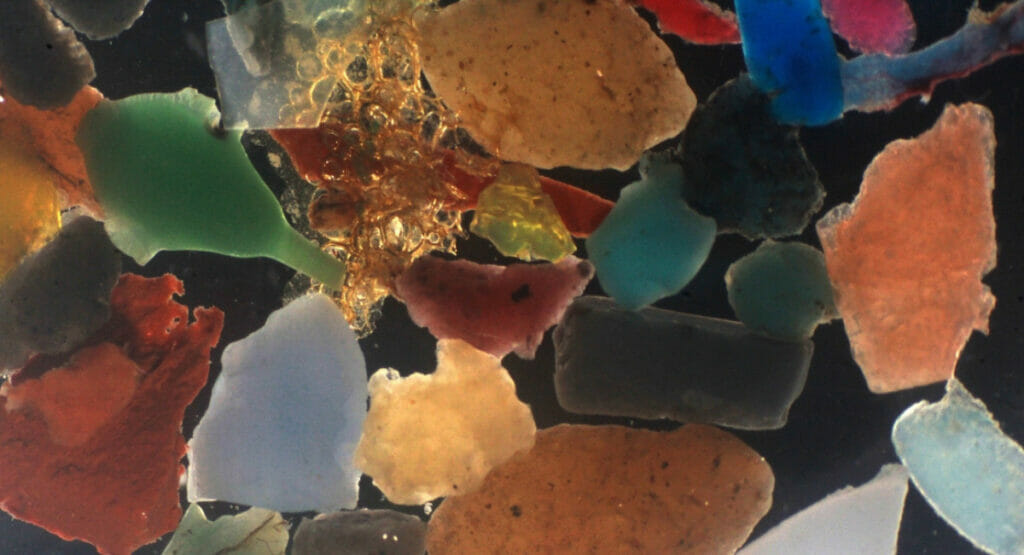

Goudriaan had a special plastic manufactured especially for these experiments with a distinct form of carbon (13C) in it. When she fed that plastic to bacteria after pretreatment with „sunlight“ – a UV lamp – in a bottle of simulated seawater, she saw that special version of carbon appear as CO2 above the water. „The treatment with UV light was necessary because we already know that sunlight partially breaks down plastic into bite-sized chunks for bacteria,“ the researcher explains.

„This is the first time we have proven in this way that bacteria actually digest plastic into CO2 and other molecules,“ Goudriaan states. It was already known that the bacterium Rhodococcus ruber can form a so-called biofilm on plastic in nature. It had also been measured that plastic disappears under that biofilm. „But now we have really demonstrated that the bacteria actually digest the plastic.“

When Goudriaan calculates the total breakdown of plastic into CO2, she estimates that the bacteria can break down about one percent of the available plastic per year.

„That’s probably an underestimate. We only measured the amount of carbon-13 in CO2, so not in the other breakdown products of the plastic. There will certainly be 13C in several other molecules, but it’s hard to say what part of that was broken down by the UV light and what part was digested by the bacteria.“

Maaike Goudriaan

Even though marine microbiologist Goudriaan is very excited about the plastic-eating bacteria, she stresses that microbial digestion is not a solution to the huge problem of all the plastic floating on and in our oceans.

„These experiments are mainly a proof of principle. I see it as one piece of the jigsaw, in the issue of where all the plastic that disappears into the oceans stays. If you try to trace all our waste, a lot of plastic is lost. Digestion by bacteria could possibly provide part of the explanation.“

To discover whether ‘wild’ bacteria also eat plastic ‘in the wild’, follow-up research needs to be done. Goudriaan already did some pilot experiments with real sea water and some sediment that she had collected from the Wadden Sea floor.

„The first results of these experiments hints at plastic being degraded, even in nature. A new PhD student will have to continue that work. Ultimately, of course, you hope to calculate how much plastic in the oceans really is degraded by bacteria. But much better than cleaning up, is prevention. And only we humans can do that.“

Maaike Goudriaan

Source: NIOZ

More packaging news

A contract with a handshake is valid

Managing director Tina Gerfer of Wilhelm Rasch Spezielmaschinenfabrik has modernized the company and successfully guided it through difficult times.

Asynchronous servo solutions for the packaging industry

From primary packaging to final packaging, electric drives play an important role. With a broad portfolio, Nord Drivesystems supports customers.

Label Durability

Labels offer many functions which can get lost due to label removal. PTS assesses labels and cardboard for durability and tamper evidence.

More design for recycling for cosmetics packaging

Packaging for decorative cosmetics is very special. The Forum Rezyklat calls for the recyclability of packaging to be taken into account when designing it.

Innovation Barometer 2024

According to a survey conducted by Aktionsforum Glasverpackung 2024 is set to be a highly innovative year for glass packaging.

Flexible packaging system for natural cosmetics

Sustainability is part of Weleda’s identity. IWK is also contributing to this with its new flexible packaging line for many natural cosmetic products.