If you look at the trends in the food industry from a packaging point of view, ecological sustainability will be the defining theme again this year. The eye will continue to eat along with the food, and therefore there is no way around an appetising presentation of the goods, albeit with further increased consideration of the consequences for the environment and climate.

At present, we are not only living in difficult economic times, but also in difficult political times. The high energy prices are of course not only affecting energy-intensive production, but all parts of the economy and European society. Those who believed after Corona and the supply bottlenecks that the deep valley had been passed are being rudely brought back down to earth by inflation and the energy crisis. It is important to remember that difficult times offer opportunities for change. After all, the opportunities to increase entrepreneurial flexibility, agility and efficiency through innovations, automation and digitalisation are also and especially given in times of crisis.

The food industry must also follow the changing consumer behaviour and with it the packaging issue. And this is where it gets exciting: On the one hand, the products have to be safely packaged and protected for transport; on the other hand, the packaging as a means of presentation has to be convincing and sustainable at the same time. However, many consumers are unsure which choice will keep their ecological footprint lean when shopping. They are not alone in this, because most manufacturers or users of packaging feel the same way. Packaging that may be well-intentioned but is more harmful than beneficial to the environment continues to enter the market. The waste management companies know the problem: what cannot be separated well or only has a small share in the collection of recyclable materials cannot be recycled. Then the recyclable material cycle misses out on the material and the recycler misses out on his margin. For non-recyclable materials, the only option is thermal recycling.

Recycling as a determining factor

But it is not only the social trend towards more sustainability that will dominate the future. In the future, politics will set the direction for industry with stricter regulations and recycling quotas. The background is the European Union’s Green Deal with an action plan for a functioning circular economy. In the packaging and food industry, this requires not only the use of fully recyclable materials, but also the targeted collection, clean separation and complete recycling of waste, resulting in a pure material that can be used again for the same purpose without compromise.

In the meantime, several recyclers and dual systems have already developed their own certifications with which the recyclability of the respective packaging solution is reassessed. The food industry will probably have to rely more on the use of mono-packaging materials and paper packaging. In the course of this, the trend towards plastic-free packaging, and also the trend towards „refill“ will increase. So, the crucial questions are: Where can the industry do without plastic? Where can substitute products be used, and how do I protect food from damage during transport?

Whereby consumer behaviour, as is so often the case, cannot necessarily be described as rational. More than half of the packaging produced for consumers globally is used for the food industry. The packaged product accounts for ten to a hundred times more CO2 pollution than the packaging. The protective and shelf-life function of packaging that is suitable for the product is indispensable, and consumers are often not sufficiently aware of it. The packaging industry must take this aspect into account in the future and positively influence customer expectations by using mono-materials and information.

Flexibility and efficiency as the be-all and end-all

So, what matters in food packaging is maximum flexibility and efficiency as the linchpin for success. Especially in a market environment with enormously high competitive pressure and constantly changing consumer behaviour, as well as the rapidly increasing social expectations for more sustainability, flexible, agile and efficient automation solutions are the key to the future of food packaging.

Food manufacturers can draw on the combined expertise of an experienced team of experts at packaging machine manufacturer Schubert. The long-established company offers highly automated flexible packaging processes for all products in the food industry, regardless of whether they are fresh produce, dairy products, frozen foods, long-life foods, baked goods or the ever-growing market for convenience food. Fully automated robot-supported total solutions, from the feeding of goods to the finished product dispatch, increase efficiency, future-proofing and thus the profitability of companies. Robotics and digitalisation are changing the value chains not only in the packaging industry, but for all production processes.

Supporting technologies

The trend towards ever faster product changes and alterations also means that the machines have to be adapted with the appropriate format parts – a time-consuming and cost-intensive undertaking in times of supply bottlenecks and scarce raw materials. This is where the use of 3D printing offers a comprehensive and sustainable solution in tool manufacturing. For example, Schubert customers can use Partbox, a complete package consisting of a virtual streaming platform, a self-developed 3-D printer and suitable plastic material, to produce the required plastic parts in their own production using 3-D printing.

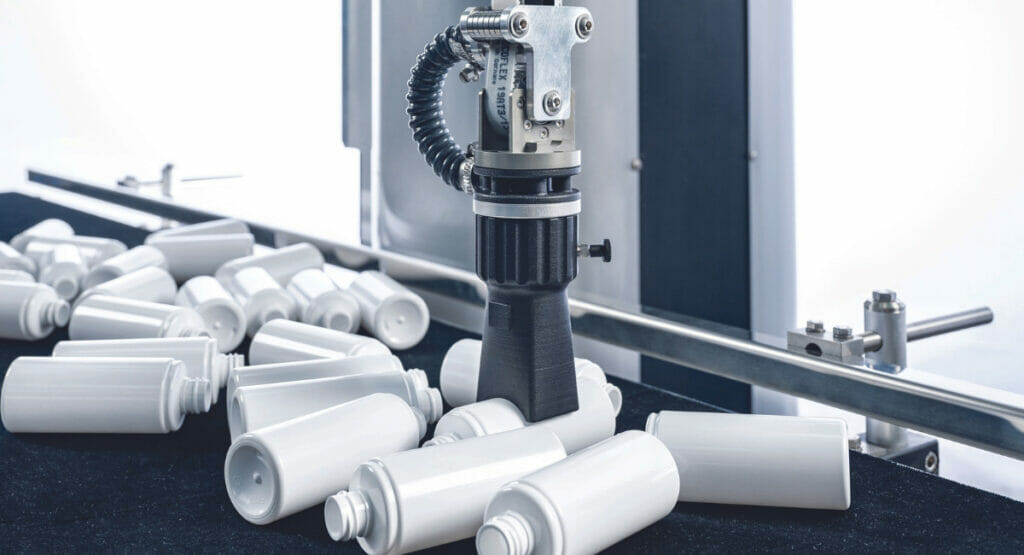

Another addition to the optimised workflow in production is the use of image processing systems as quality control in the continuous packaging process. If we think further, this leads to artificial intelligence (AI) and neural networks which, as self-learning systems, recognise relevant product features and automatically determine user parameters: an application that Schubert has already strongly advanced with the development of its Cobot. As support in the feeding process at the machine, the Cobot independently learns new products and perfects the automated process. In this way, digitalisation helps food manufacturers to react faster, more flexibly and more efficiently to changes in their production. Schubert offers exactly the kind of response that the packaging industry will need in the future thanks to the modular design of the packaging machines, the fastest possible format changes and optimally coordinated processes.

Thinking about processes holistically

It can be assumed that the megatrend of sustainability will continue to strongly influence the food industry through rapidly changing consumer behaviour and the advancing digitalisation of society. Here, the actual products are only part of the overall process. Sales, logistics and also production are part of a value creation process that will be readjusted through digitalisation and automation in the coming years. Only by increasing efficiency, flexibility and agility can this megatrend be successfully countered in all its facets. For this, packaging processes must be thought of holistically and also more broadly: from the choice of packaging material to feeding, the various packaging steps and transport to the recycling process of the packaging after consumption.

In principle, the focus in the future will be on avoiding plastic and substituting it with paper. Where plastic cannot be dispensed with, mixed packaging will be replaced by recyclable mono-material packaging to make it more attractive for the recycling industry. Having a partner in the production process who is a master of the material mix will be a decisive competitive advantage. For this reason, Schubert is currently building up comprehensive expertise in the field of packaging materials with the support of industry partners.

The content is not only far-reaching data on the machinability and recyclability of materials, but also the development and optimisation of packaging and sustainability consulting along the entire supply chain.

Accordingly, the key to the future does not lie in innovative technical silo solutions, but in a holistic approach that considers all parameters of a seamless integrative packaging process in the food industry. Therefore, it is still a matter of facing the future with new ideas, courage and curiosity. This will not change in the years to come.

More packaging news

Asynchronous servo solutions for the packaging industry

Label Durability

More design for recycling for cosmetics packaging

Innovation Barometer 2024