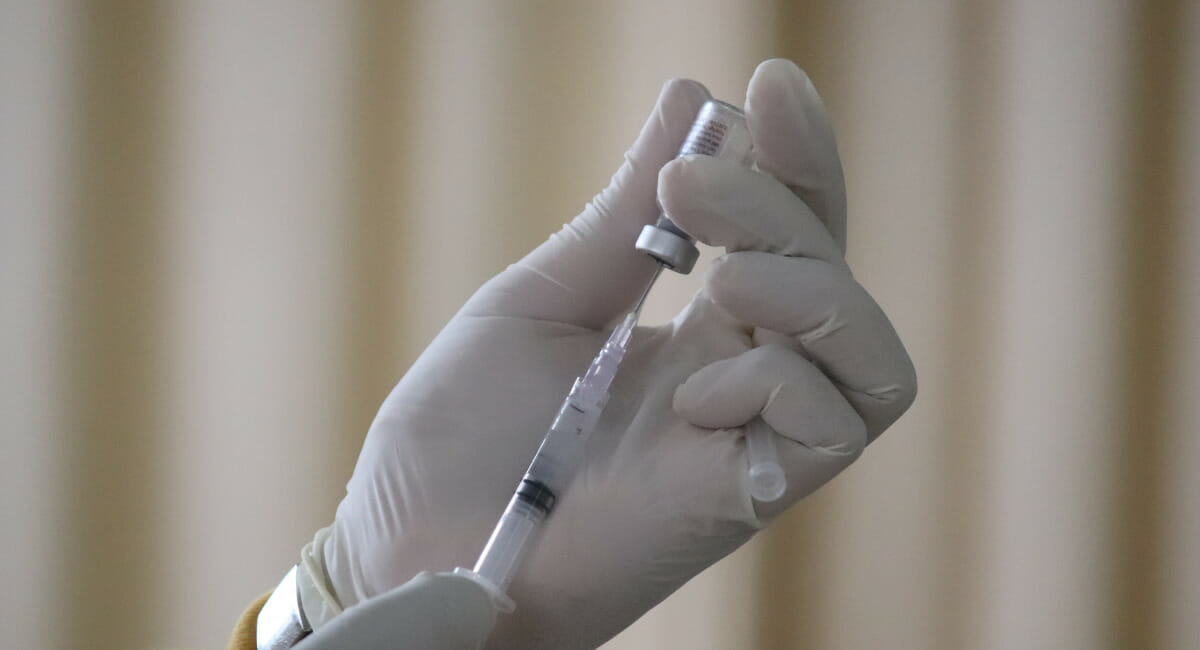

TPE-based pharmaceutical stoppers outperform rubber

Pharmaceutical stoppers made of butyl rubber are often used for injection and drug vials. A look at alternative materials, such as thermoplastic elastomers (TPE), today is all the more worthwhile.