What do a car racetrack in the children’s room, an individually assembled food box for the relaxed preparation of favourite meals and the start in automation have in common? Curious about drive and automation technology that arrives at the machine builder? This way to the machine automation solutions …

Packaging machines are an indispensable part of the process in a wide range of industries. Their automation, functions and movements are determined by product characteristics such as size, weight, volume and, especially in the case of food or pharmaceuticals, a multitude of other criteria. Quick changeovers and frequent product changes require a modular and flexible machine design. At the same time, many application and movement sequences are comparable. This approach offers the possibility of simplification through standardisation.

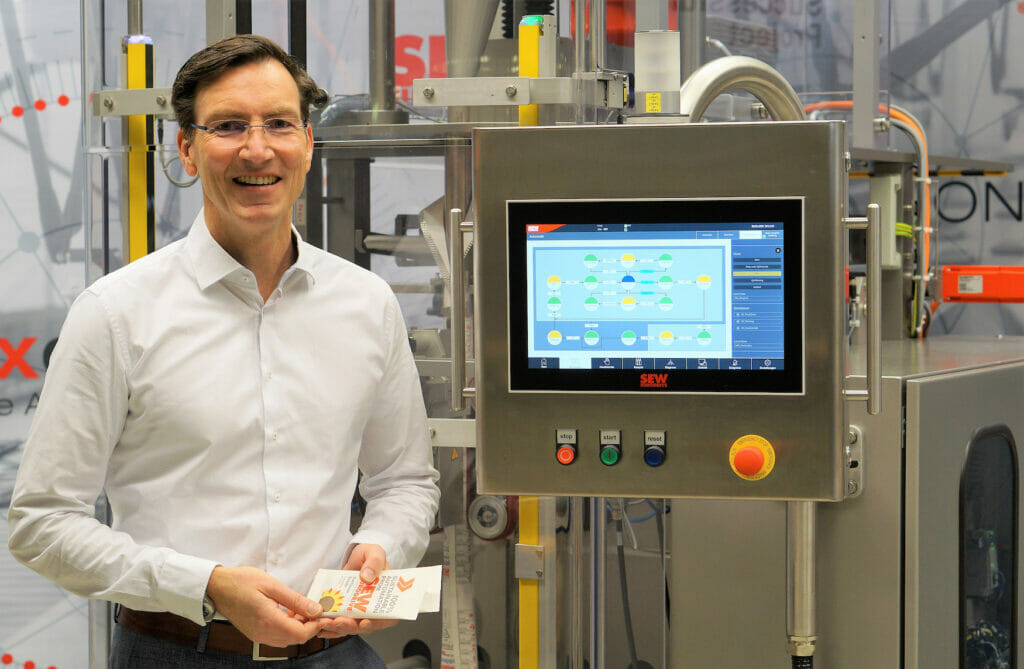

With the image of a conveniently adapted cooking box for a meeting in the kitchen in mind, SEW-Eurodrive packs ready-made automation packages. With this strategy, the Bruchsal-based company is going beyond the approach of prepared technology templates. But what is behind the new „StarterSet“? Alexander Hack, Strategic Portfolio Manager at SEW-Eurodrive, provides information about this:

Mr Hack, in the automation industry people often talk about a kit, so what is so different about your company's StarterSet?

But it doesn't stop there, not even in the children's room.

How should one imagine a StarterSET, for example for a packaging machine from the food sector?

That sounds a lot like a complete cooking box that contains all the recipes you need for a two-course meal in addition to the ingredients. Apart from the hardware, how is this concept implemented in the software?

Does the customer need to know in advance how his machine is to be driven and, if necessary, automated? After all, there are many ways to reach the goal.

How do users benefit from this?

What is the path like?

Which users are the focus of the new StarterSet?

More packaging news

A contract with a handshake is valid

Managing director Tina Gerfer of Wilhelm Rasch Spezielmaschinenfabrik has modernized the company and successfully guided it through difficult times.

Asynchronous servo solutions for the packaging industry

From primary packaging to final packaging, electric drives play an important role. With a broad portfolio, Nord Drivesystems supports customers.

Label Durability

Labels offer many functions which can get lost due to label removal. PTS assesses labels and cardboard for durability and tamper evidence.

More design for recycling for cosmetics packaging

Packaging for decorative cosmetics is very special. The Forum Rezyklat calls for the recyclability of packaging to be taken into account when designing it.

Innovation Barometer 2024

According to a survey conducted by Aktionsforum Glasverpackung 2024 is set to be a highly innovative year for glass packaging.

Flexible packaging system for natural cosmetics

Sustainability is part of Weleda’s identity. IWK is also contributing to this with its new flexible packaging line for many natural cosmetic products.