The string labelling system from Logopak, in conjunction with the use of linerless labels that do not require silicone-coated label backing paper, optimally fulfils the ecological catalogue of requirements of the Rothaus State Brewery in Baden. In addition, the system solution provides transport security and labelling of loaded pallets in a single operation.

Since 1791, beer has been brewed in Rothaus, located at an altitude of around 1,000 metres in a district of Grafenhausen in the Upper Black Forest. Situated in a beautiful landscape, committed to an environment fit for life and aware of the importance of pure brewing water for the quality of the beers, the company already felt committed to sustainable management at a time when the idea of environmental protection was far from being a common good and of any social value. The company demonstrates its high level of personal responsibility in terms of sustainability by, among other things, using 100 per cent regional green electricity from hydroelectric plants, generating solar thermal energy on its building roofs, introducing environmental and energy management systems, and strongly considering energy efficiency and sustainability criteria when investing in production facilities and processes.

Pallet labelling according to the "Purity Law

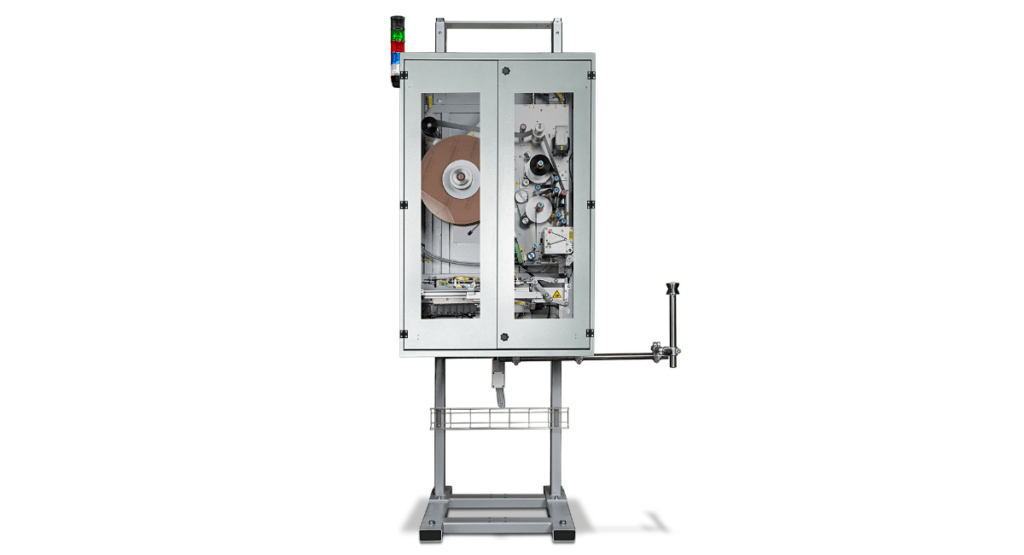

According to the Purity Law, only hops, malt, yeast and water should be used to brew beer in Germany, without any other ingredients. Transferred to the labelling technology of beer pallets, this means that, as far as possible, only waste-avoiding and environmentally friendly techniques and materials should be used, even without „ingredients“ such as disposable plastic films, silicone-coated carrier paper waste or unnecessary CO2 pollution of the environment. For the Badische Staatsbrauerei Rothaus, it was therefore only logical and consistent to opt for a consistently sustainable eco-labelling solution in the sense of the „Purity Law“ with the Logomatic 920 PSCK cord labelling system and the use of liner-free labels. It fulfils these ecological aspects as well as the economic requirements for high-performance pallet labelling that complies with the GS1 standard.

Focus on sustainable management

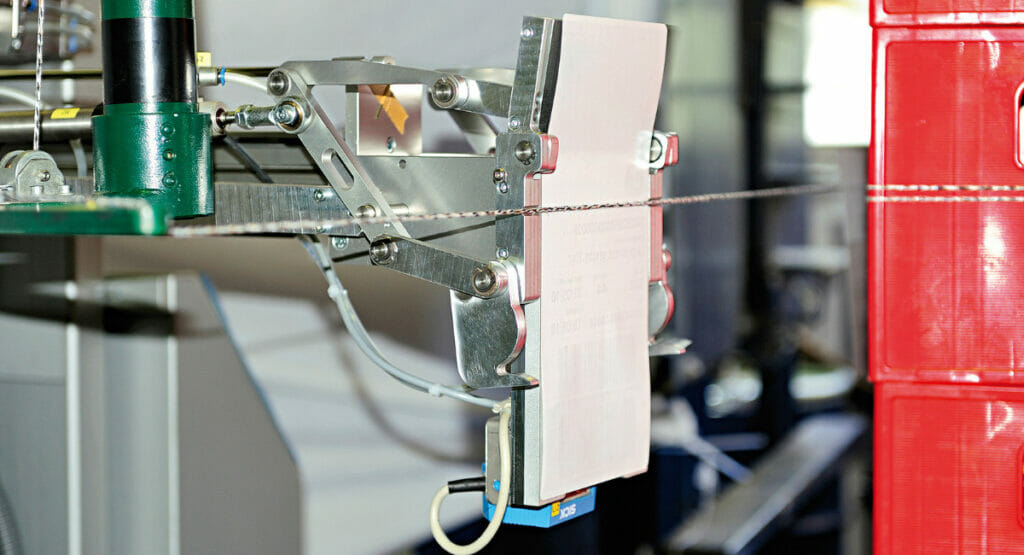

With the Logomatic 920 PSCK cord labelling system, Badische Staatsbrauerei Rothaus has opted for a labelling solution that combines two process steps in one. It secures the pallets loaded with beer crates with a reusable securing cord made from recycled textile fibres.

At the same time, it generates two labels per pallet in real time with all the important information from Rothaus‘ IT system, for example the number of the shipping unit (NVE), the article number, the batch ID and the best-before date (MHD), and attaches them to the securing cord. The label is folded over the string so that the adhesive sides adhere to each other. In the end-of-line area of the Rothaus palletising system, up to 85 pallets are labelled on both sides per hour. It takes less than ten seconds to print and apply a GS1 label. The integrated height adjustment of the labelling system with 300 millimetres of travel enables the cord and the labels to be attached variably to the pallet at the desired height.

To ensure consistent identification security along the supply chain from the brewery to the retailer, the codes and clear text are verified for readability directly after printing and in the event of a „bad read“, a replacement label is generated immediately. Every error-free reading cycle is reported back to the IT system via the LogoSoft software with the data relevant to the application or industry. For incompletely loaded pallets, Rothaus uses the Logomatic 920 PSCK’s residual pallet handling mode. The system operator records the quantity of beer crates on the pallet via the touch display, removes the dispensed labels and attaches them to the securing cord.

Linerless labels improve eco-balance

The Logomatic 920 PSCK cord labelling system meets the demand for ecologically sound pallet labelling in many ways. The securing cord made of recycled textile fibres replaces the stretch films often used to secure loads. The consumption of plastic is completely eliminated and also in the cost balance per pallet, the cord performs significantly better than the film. In addition, the immediate reusability of the beer crates is simplified: while peeling off labels applied directly to the load carrier often leaves unsightly and unhygienic material and adhesive residues that have to be removed at great expense, the cord labelling system does not create any residues.

Further plus points result from operating the labelling system with linerless labels, whose paper itself is FSC-certified. Due to their special cold-seal coating, these labels do not require any silicone-coated backing material. This means there is no liner waste, which is costly and time-consuming to dispose of. Without the backing material, the run length per label roll is 50 to 60 per cent longer. This means that it has a better usable capacity compared to conventional thermal transfer rolls. Accordingly, the rolls in the labelling system at Rothaus need to be changed less frequently. This improves the system and process availability of the end-of-line palletising system. In addition, Rothaus has to procure fewer label reels for the required labelling volume. This saves a considerable amount of effort and CO2 emissions in procurement and replenishment logistics and improves the CO2 footprint.

More packaging news

A contract with a handshake is valid

Managing director Tina Gerfer of Wilhelm Rasch Spezielmaschinenfabrik has modernized the company and successfully guided it through difficult times.

Asynchronous servo solutions for the packaging industry

From primary packaging to final packaging, electric drives play an important role. With a broad portfolio, Nord Drivesystems supports customers.

Label Durability

Labels offer many functions which can get lost due to label removal. PTS assesses labels and cardboard for durability and tamper evidence.

More design for recycling for cosmetics packaging

Packaging for decorative cosmetics is very special. The Forum Rezyklat calls for the recyclability of packaging to be taken into account when designing it.

Innovation Barometer 2024

According to a survey conducted by Aktionsforum Glasverpackung 2024 is set to be a highly innovative year for glass packaging.

Flexible packaging system for natural cosmetics

Sustainability is part of Weleda’s identity. IWK is also contributing to this with its new flexible packaging line for many natural cosmetic products.