Preparing chocolate specialties of exquisite quality is Lake Champlain Chocolates’ passion. For nearly 40 years, this family enterprise based in North America has been making its products by relying on regional ingredients and a winning combination of creativity, craftsmanship, and efficiency. When it comes to chocolate bar packaging, the premium chocolate manufacturer puts its trust in the system solutions of Loesch Verpackungstechnik (LoeschPack) in Altendorf.

Whether Birthday, Thanksgiving, Christmas, or Valentine’s Day, the production of Lake Champlain Chocolates’ regionally renowned chocolates almost always plays a role in the celebration of special occasions and holidays throughout the year, when the elegant creations in premium packaging are given as gifts. Other products such as chocolate bars are available all year round. The family-owned company’s 8000-square-meter headquarters are located in Williston, Vermont, near the Canadian border and a lake that gives the company its name. The company facility is also not far from an idyllic landscape of forested hills and quaint towns and villages.

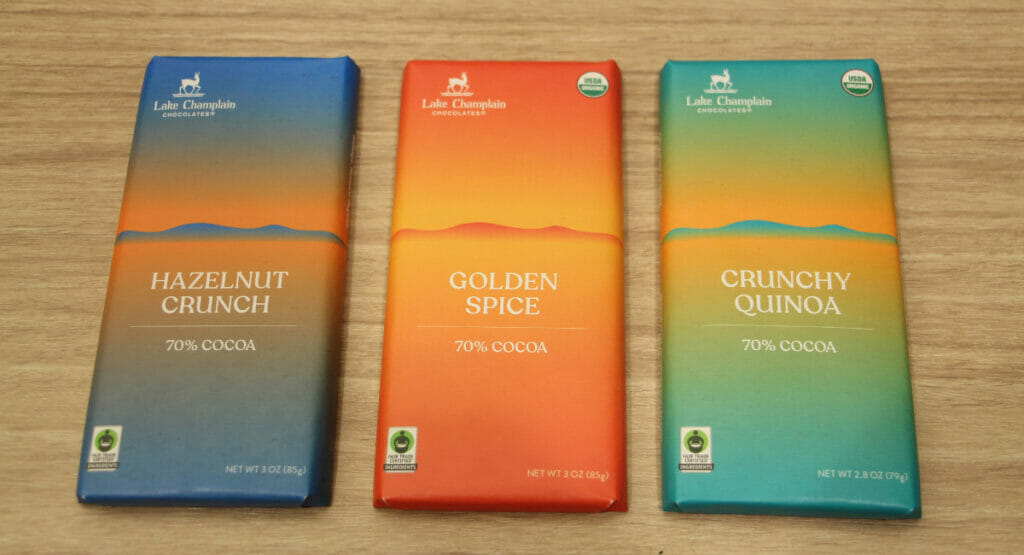

As you pass through the large warehouse and into the production area, you can smell the delicious aromas of chocolate, maple syrup, and roasted nuts. The enticing scent of scrumptious treats from artisanal manufacture hangs in the air as the finest chocolate creations and truffle candies, primarily from seasonal products made all year round, come off the production line here. Each of these products differs in their production as well as packaging, with some produced and packaged by machine in automated or semi-automated processes while others are created entirely by hand. That means that some product lines are quite elaborate and labor intensive, while others require a small number of manual operations. This applies to products such as LoeschPack’s chocolate bar packaging line, which can automatically pack up to 200 chocolate bars per minute.

Just a 15-minute drive from the company building, tourist hotspot Burlington is home to two of the family-owned company’s three retail stores. These stores feature integrated cafés where visitors can not only get a taste of gourmet chocolates and other sweet treats but also watch how certain products are created and learn where chocolate comes from. During the peak season, up to 140 employees work to produce, package, and sell Lake Champlain’s sweet creations. The tasty treats are also available far beyond the borders of the United States and can be purchased in both Canada and Australia.

LoeschPack delivers the perfect solution

Over the course of many years, Lake Champlain has made a name for itself with handcrafted chocolate bars, packaged products, and seasonal items, evolving along the way from a brand exclusively serving the northeastern market of the United States to a nationally known favorite. In the course of further development of its products and equipment in the direction of greater automation, the chocolatier reorganized its packaging technology system for chocolate bars in 2018. With the aim of increasing bar production, Lake Champlain first upgraded its chocolate pouring line.

However, to ensure smooth implementation, the company also needed a packaging system that could keep up with the new production. To meet this need, LoeschPack supplied an appropriate two-stage fold wrapping machine.

“We got to know LoeschPack many years ago at the interpack and PackExpo trade shows. On the lookout for a supplier that could help us make the move from an open fold wrap to a sealed full wrap system, we learned that LoeschPack already had the right solution for making our idea a reality. The US market for chocolate bars, which had traditionally sold its products in the horizontal orientation, had changed over time. More and more retailers were now placing the chocolate bars into the wrapper vertically. That meant less protection for our products, which were wrapped with foil at the ends. We took a look at a comparable LoeschPack machine available on the market and were thrilled.”

Eric Lampman, President Lake Champlain Chocolates

“Our solution consists of the LOMATIC feeding and distribution system with integrated belt buffer and the LTM-DUO packaging machine. The system takes the bars from the upstream pouring line, properly arranges them, and feeds them to the downstream packaging machine. An additional belt buffer in the LOMATIC can buffer the products for a brief period of time and then return them to production. This compensates for fluctuations in production flow and increases the efficiency of the overall system. The LTM-DUO first packs and hermetically seals the chocolate bars and then wraps them in paper or cardboard.” From the start of the project to commissioning took around nine months, during which the two companies worked intensively on the project. They were successful in this endeavor, as confirmed by John Weishaar, Manufacturing Manager at Lake Champlain: “With the new pouring line and packaging system, we were able to triple our original throughput while also increasing the quality of our packaging. As an improvement over the old machine, for the past four years the new system solution has been making it possible for us to hermetically seal our chocolate bars on both ends, lengthening the product shelf life.”

Christoph Bächmann, Project Manager at LoeschPack

Sustainably producing and packaging chocolate

In addition to their shared success on this project, Lake Champlain and LoeschPack also share the philosophy that their businesses should operate on a sustainable basis. With the system solution from Altendorf, the chocolate manufacturer can produce its bars not only faster and with higher quality but also more sustainably.

“The LTM-DUO is easy to operate and requires minimal staff and service. It can package many different recipes, from milk chocolate to chocolate with whole nuts, and it does so with little effort – the customer can change the recipe and format easily, quickly, and on a user-friendly basis. At the same time, Lake Champlain remains flexible when choosing between the two packaging materials. The switch from aluminum foil to OPP foil at the first station is just as easy as the changeover from paper to cardboard in the step that follows. The LTM-DUO, which is easily accessible in all areas, is easy to clean once the chocolate bars leave the belt.”

Christoph Bächmann

When we consider matters beyond the partnership with LoeschPack, it is also obvious that Lake Champlain places a great deal of emphasis on premium packaging, products, and ingredients: “Over the past 12 years, we’ve put our focus more and more on natural and ‘green’ products as well as simple recipes. To make all of this a reality, we primarily use sustainably produced chocolate and other environmentally friendly raw materials while avoiding certain ingredients such as palm oil. When possible, we work with local farmers and suppliers to better achieve these objectives,” Lampman reports, providing the following as an example:

„To make our caramel, we use fresh organic dairy products from the region, and we use local products for flavor like Vermont maple syrup and Mad River Distillers Bourbon. We also sweeten some of our confections with local honey as well as other exquisite flavors prepared in-house. For our gift packaging, we largely use paper and cardboard that is recycled completely within the region. All this is important to us as a family and as a maker of good food.” But when it comes to packaging technology, Americans put their faith in machines “Made in Germany.”

Shared knowledge and direct communication

Good communication and the expertise of everyone involved also played a key role in the success of the project: “Our work with LoeschPack has been great so far because we’ve been able to draw not only on our own resources but also on the knowledge, experience, and perspectives of the experts from Germany,” Lampman says. The technicians from Altendorf successfully installed the machines with the assistance of the machine operators from the North American company: “LoeschPack did a great job coordinating the machine installation,” says Weishaar with satisfaction.

“During commissioning, the colleagues from LoeschPack correctly assessed the system and its potential in a professional manner – and we were also able to learn a lot from the skills demonstrated by the German experts: For example, how do the systems run, and what capabilities do the machines possess? It quickly became clear to us that the new system would also set a new benchmark and take us to the next level as a chocolate manufacturer. We are of course quite grateful to the experts from Germany for the valuable exchange of information and the successful project. The numbers speak for themselves. They are proof that the technology is good and that our investment has paid off.”

Eric Lampman

The interaction with Loesch Support went just as well. The system can be connected remotely so that the team in Germany can perform remote maintenance at the touch of a button. “If we need spare parts, we can quickly have them delivered,” Weishaar reports. Lake Champlain and LoeschPack both find a culture of respectful and straightforward communication to be important, Lampman reports: “We appreciated the open communication we experienced from the outset. If something wasn’t right, we talked about it and together examined what we could do to improve things, what we could do differently, and what new approaches we wanted to try out. We see authenticity as well as open and honest dealings with one another as important values that we live by as a family business.”

“We cultivate a grounded partnership with our customers. The working atmosphere with our colleagues from Vermont is very congenial, and the employees are committed and seem proud to be associated with the chocolate manufacturer, for which many have worked for decades. It was a great project in which we, as a packaging equipment manufacturer with our core competence in chocolate packaging, were able to contribute to a medium-sized, up-and-coming company with products that are both exciting and delicious.”

Christoph Bächmann

Bächmann looks to the future with a positive attitude: “We naturally hope that we can continue to support Lake Champlain with our packaging solutions far into the future and continue to grow together with them along the way.” With the bars and chocolates made in Williston, you don’t have to look far for sweet gift ideas that make for the perfect holiday.

More packaging news

Asynchronous servo solutions for the packaging industry

Label Durability

More design for recycling for cosmetics packaging

Innovation Barometer 2024